3K carbon fiber features 3,000 filaments per tow, offering a balance of strength, weight, and flexibility ideal for high-performance applications like aerospace and sports equipment. In contrast, 12K carbon fiber contains 12,000 filaments per tow, resulting in higher strength and stiffness but increased weight, making it suitable for larger structural components. Selecting between 3K and 12K carbon fiber depends on the specific demands of weight, durability, and cost for the intended use.

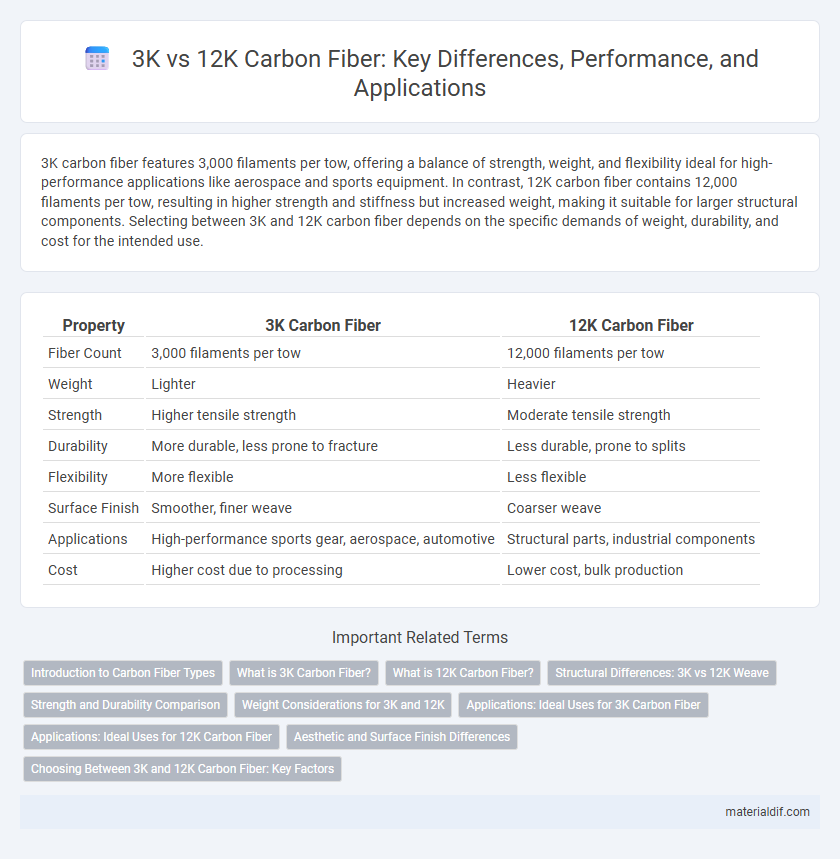

Table of Comparison

| Property | 3K Carbon Fiber | 12K Carbon Fiber |

|---|---|---|

| Fiber Count | 3,000 filaments per tow | 12,000 filaments per tow |

| Weight | Lighter | Heavier |

| Strength | Higher tensile strength | Moderate tensile strength |

| Durability | More durable, less prone to fracture | Less durable, prone to splits |

| Flexibility | More flexible | Less flexible |

| Surface Finish | Smoother, finer weave | Coarser weave |

| Applications | High-performance sports gear, aerospace, automotive | Structural parts, industrial components |

| Cost | Higher cost due to processing | Lower cost, bulk production |

Introduction to Carbon Fiber Types

3K carbon fiber consists of 3,000 individual filaments bundled together, offering a balance of strength, flexibility, and lightweight properties ideal for precision applications like drone frames and sporting goods. In contrast, 12K carbon fiber bundles 12,000 filaments, resulting in higher stiffness and strength suitable for automotive parts, aerospace components, and larger structural elements. Both types are valued for their exceptional strength-to-weight ratio, but selection depends on the required mechanical performance and surface finish quality.

What is 3K Carbon Fiber?

3K carbon fiber consists of 3,000 individual carbon filaments bundled together to form a single tow, offering a balance between strength and weight ideal for lightweight applications like aerospace and sporting goods. Compared to 12K carbon fiber, which contains 12,000 filaments, 3K fiber delivers a finer weave with greater flexibility and aesthetics, making it preferred for precision components and surface finishes. Its high tensile strength and excellent stiffness contribute to superior performance in composites requiring enhanced mechanical properties and reduced material thickness.

What is 12K Carbon Fiber?

12K carbon fiber consists of 12,000 individual carbon filaments bundled into a single tow, providing a balance of strength, stiffness, and weight ideal for high-performance applications. Compared to 3K carbon fiber, which contains 3,000 filaments per tow, 12K fiber offers increased durability and structural integrity but typically results in a heavier and slightly less flexible material. This makes 12K carbon fiber suitable for automotive parts, aerospace components, and sporting equipment where enhanced mechanical properties are essential.

Structural Differences: 3K vs 12K Weave

3K carbon fiber features 3,000 filaments per tow, creating a finer, more pliable weave ideal for detailed applications and improved drape, while 12K carbon fiber comprises 12,000 filaments per tow, resulting in a coarser, stiffer weave that offers higher strength and enhanced durability for structural uses. The 3K weave provides smoother surface finishes and better conformity to complex shapes due to its lighter bundle size, whereas the 12K weave delivers increased stiffness and impact resistance, making it suitable for heavy-duty engineering components. Structural differences between 3K and 12K carbon fibers directly influence mechanical performance, weight, and cost, guiding material selection based on application-specific strength and flexibility requirements.

Strength and Durability Comparison

3K carbon fiber features 3,000 filaments per tow, resulting in a finer weave that offers higher tensile strength and enhanced durability compared to 12K carbon fiber, which contains 12,000 filaments per tow but has a coarser texture. The higher filament density of 3K carbon fiber provides superior resistance to fatigue and impact, making it ideal for high-performance applications requiring lightweight strength. In contrast, 12K carbon fiber, while more affordable and easier to handle in larger layups, delivers lower strength-to-weight ratio and durability, limiting its use in critical structural components.

Weight Considerations for 3K and 12K

3K carbon fiber features approximately 3,000 filaments per tow, resulting in a lighter, more flexible material ideal for applications where weight reduction is critical. In contrast, 12K carbon fiber consists of around 12,000 filaments per tow, offering higher strength but increased weight, making it suitable for structural parts requiring enhanced durability. Weight considerations favor 3K carbon fiber in aerospace and sporting goods, while 12K carbon fiber is often chosen for automotive and industrial uses where strength outweighs minimal weight savings.

Applications: Ideal Uses for 3K Carbon Fiber

3K Carbon Fiber, characterized by its 3,000 filaments per tow, is ideal for lightweight applications requiring high strength and fine surface finish, such as aerospace components, high-performance bicycles, and sporting equipment. Its finer weave compared to 12K Carbon Fiber ensures enhanced precision and aesthetic appeal, making it suitable for visible parts where smooth texture and detailed molding are essential. This type of carbon fiber excels in applications demanding a balance of stiffness, durability, and reduced weight without compromising the material's sleek appearance.

Applications: Ideal Uses for 12K Carbon Fiber

12K carbon fiber offers enhanced strength and stiffness compared to 3K carbon fiber, making it ideal for demanding applications such as aerospace components, automotive parts, and high-performance sporting goods where structural integrity is critical. Its larger tow size supports quicker manufacturing processes and cost efficiency in mass production without compromising durability. Industries requiring robust, lightweight materials for load-bearing structures prefer 12K carbon fiber due to its superior mechanical properties and consistent performance under stress.

Aesthetic and Surface Finish Differences

3K carbon fiber features 3,000 filaments per tow, producing a finer, more intricate weave with a high-gloss, smooth surface finish ideal for aesthetic applications requiring detailed patterns. In contrast, 12K carbon fiber contains 12,000 filaments per tow, resulting in a coarser, more pronounced weave with a matte or textured surface that emphasizes strength over intricate visual detail. The 3K variant is preferred for parts where visual appeal is critical, while 12K is favored in structural components where a rugged finish is acceptable or desired.

Choosing Between 3K and 12K Carbon Fiber: Key Factors

3K carbon fiber features 3,000 filaments per tow, offering a smoother finish, higher flexibility, and better compatibility with complex shapes, ideal for lightweight, precision applications. In contrast, 12K carbon fiber contains 12,000 filaments per tow, providing greater strength and stiffness at the cost of added weight and coarser texture, suited for structural components requiring higher load-bearing capacity. Choosing between 3K and 12K carbon fiber depends on balancing requirements for strength, weight, surface finish, and flexibility in the specific application.

3K Carbon Fiber vs 12K Carbon Fiber Infographic

materialdif.com

materialdif.com