Carbon nanorods and carbon nanoplatelets are both advanced carbon nanomaterials with distinct structural shapes influencing their properties and applications. Carbon nanorods have a rod-like morphology that provides high aspect ratios and enhanced mechanical strength, making them ideal for reinforcing composite materials. In contrast, carbon nanoplatelets possess a flat, plate-like structure that offers excellent surface area and thermal conductivity, beneficial for electronic and thermal management applications.

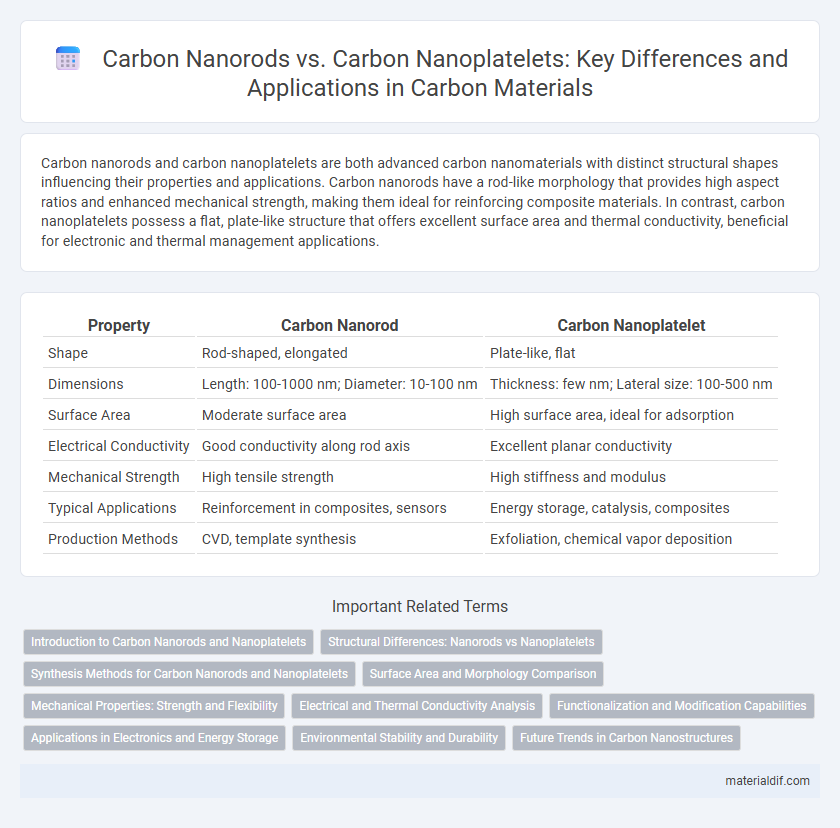

Table of Comparison

| Property | Carbon Nanorod | Carbon Nanoplatelet |

|---|---|---|

| Shape | Rod-shaped, elongated | Plate-like, flat |

| Dimensions | Length: 100-1000 nm; Diameter: 10-100 nm | Thickness: few nm; Lateral size: 100-500 nm |

| Surface Area | Moderate surface area | High surface area, ideal for adsorption |

| Electrical Conductivity | Good conductivity along rod axis | Excellent planar conductivity |

| Mechanical Strength | High tensile strength | High stiffness and modulus |

| Typical Applications | Reinforcement in composites, sensors | Energy storage, catalysis, composites |

| Production Methods | CVD, template synthesis | Exfoliation, chemical vapor deposition |

Introduction to Carbon Nanorods and Nanoplatelets

Carbon nanorods and carbon nanoplatelets represent distinct nanostructures with unique morphologies and properties crucial for advanced material applications. Carbon nanorods exhibit elongated cylindrical shapes with high aspect ratios, enhancing electrical conductivity and mechanical strength, while carbon nanoplatelets are characterized by thin, flat, platelet-like structures offering large surface areas and superior thermal stability. These differences impact their functionality in composites, energy storage, and catalysis, making the choice between nanorods and nanoplatelets essential for optimizing performance in nanomaterial engineering.

Structural Differences: Nanorods vs Nanoplatelets

Carbon nanorods exhibit a cylindrical morphology with high aspect ratios, promoting anisotropic properties and enhanced electrical conductivity along their length. In contrast, carbon nanoplatelets possess a flat, layered structure with a high surface area, offering superior mechanical reinforcement and thermal conductivity in composite materials. The distinct structural differences between nanorods and nanoplatelets influence their application versatility, where nanorods excel in electron transport and nanoplatelets enhance material strength and heat dissipation.

Synthesis Methods for Carbon Nanorods and Nanoplatelets

Carbon nanorods are typically synthesized using chemical vapor deposition (CVD) and hydrothermal methods, which enable controlled growth along one dimension to achieve high aspect ratios. Carbon nanoplatelets are commonly produced via exfoliation techniques and chemical oxidation, facilitating the formation of thin, flat structures with high surface areas. Both synthesis approaches are optimized to tailor morphological properties critical for applications in energy storage, catalysis, and nanocomposites.

Surface Area and Morphology Comparison

Carbon nanorods exhibit a high surface area due to their elongated, cylindrical morphology, which enhances interaction sites for catalytic and adsorption applications. In contrast, carbon nanoplatelets offer a larger planar surface area with a layered, sheet-like morphology conducive to improving electrical conductivity and mechanical reinforcement in composites. The distinct morphologies result in varying surface area-to-volume ratios, influencing their suitability for specific industrial and research applications.

Mechanical Properties: Strength and Flexibility

Carbon nanorods exhibit superior tensile strength and enhanced stiffness due to their elongated crystalline structure, making them ideal for applications requiring high load-bearing capacity. In contrast, carbon nanoplatelets offer greater flexibility and impact resistance owing to their planar geometry and larger surface area, which enable effective stress distribution and deformation. Both nanostructures provide unique mechanical property advantages, with nanorods excelling in strength and nanoplatelets in flexibility for composite material reinforcement.

Electrical and Thermal Conductivity Analysis

Carbon nanorods exhibit higher electrical conductivity due to their elongated structure, facilitating efficient electron transport along their length, while carbon nanoplatelets offer superior thermal conductivity owing to their planar morphology that promotes enhanced phonon transfer. The anisotropic properties of carbon nanorods enable directional electrical conduction, making them ideal for applications in nanoelectronics, whereas the two-dimensional nature of nanoplatelets supports effective heat dissipation in thermal management systems. Comparative studies reveal carbon nanoplatelets achieve thermal conductivity values exceeding 300 W/m*K, surpassing carbon nanorods typically ranging around 200 W/m*K, with electrical conductivity measurements favoring nanorods by approximately 30-50% under similar conditions.

Functionalization and Modification Capabilities

Carbon nanorods exhibit enhanced functionalization capabilities due to their high aspect ratio and anisotropic surface chemistry, which facilitates selective attachment of functional groups for targeted applications. Carbon nanoplatelets offer greater surface area and planar structures that enable uniform modification with various chemical moieties, improving dispersion and interfacial bonding in composites. Both nanostructures allow versatile surface modifications but differ in how their morphology influences attachment efficiency and application-specific performance.

Applications in Electronics and Energy Storage

Carbon nanorods exhibit high electrical conductivity and a one-dimensional structure, making them ideal for use in nanoscale electronic devices and as conductive additives in energy storage systems like lithium-ion batteries. Carbon nanoplatelets possess a two-dimensional morphology with exceptional surface area and mechanical strength, enhancing electrode performance in supercapacitors and flexible electronics through improved charge storage and mechanical flexibility. Both nanostructures offer unique properties that optimize energy storage efficiency and electronic device miniaturization.

Environmental Stability and Durability

Carbon nanorods exhibit enhanced environmental stability due to their elongated morphology, which provides greater resistance to mechanical stress and oxidation compared to carbon nanoplatelets. Carbon nanoplatelets, with their layered structure, offer high surface area but are more susceptible to environmental degradation and structural deformation under prolonged exposure to moisture and UV radiation. The durability of nanorods makes them preferable for applications requiring long-term stability in harsh environmental conditions, while nanoplatelets excel in scenarios demanding high surface reactivity but may require protective coatings to improve lifespan.

Future Trends in Carbon Nanostructures

Carbon nanorods exhibit superior electrical conductivity and enhanced mechanical strength, making them ideal for next-generation electronic devices and energy storage systems. Carbon nanoplatelets offer a larger surface area and improved thermal stability, suited for applications in advanced composites and thermal interface materials. Future trends in carbon nanostructures concentrate on combining these properties to develop multifunctional materials with optimized performance for flexible electronics and high-capacity batteries.

Carbon nanorod vs Carbon nanoplatelet Infographic

materialdif.com

materialdif.com