Single-walled carbon nanotubes (SWCNTs) consist of a single graphene cylinder, offering exceptional electrical conductivity and mechanical strength at a nanoscale diameter. Multi-walled carbon nanotubes (MWCNTs) feature multiple concentric graphene cylinders, providing enhanced durability and thermal stability but with slightly reduced electrical conductivity compared to SWCNTs. Applications of SWCNTs often target high-performance electronics, while MWCNTs are preferred in composite materials and structural reinforcements.

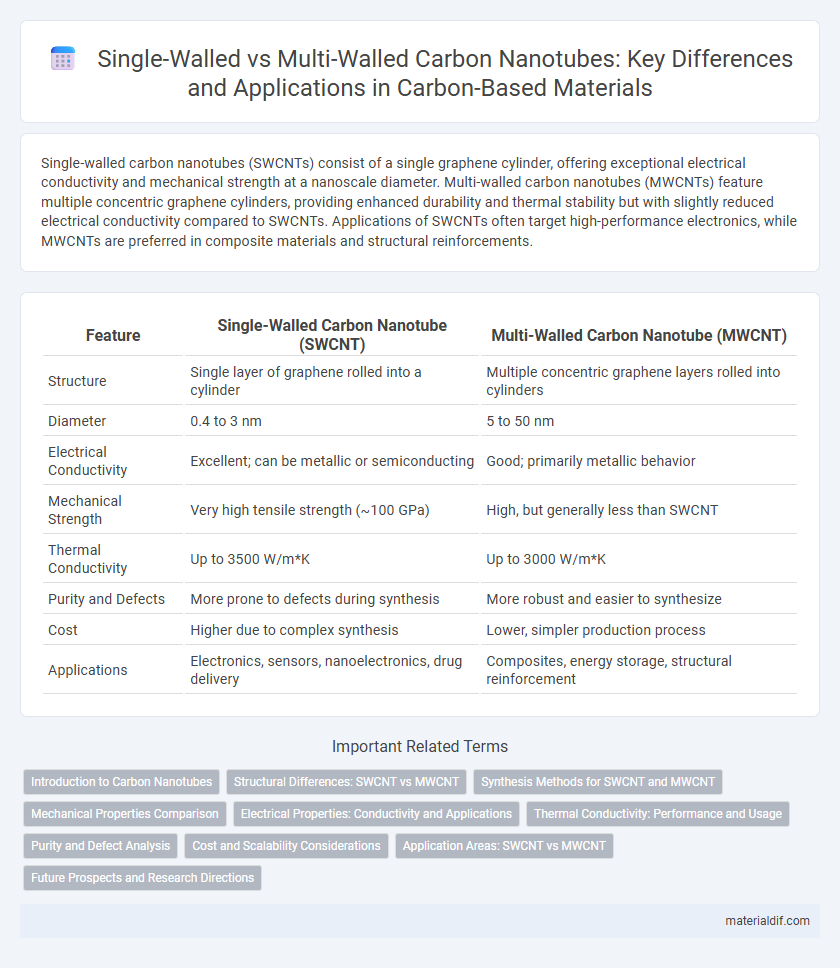

Table of Comparison

| Feature | Single-Walled Carbon Nanotube (SWCNT) | Multi-Walled Carbon Nanotube (MWCNT) |

|---|---|---|

| Structure | Single layer of graphene rolled into a cylinder | Multiple concentric graphene layers rolled into cylinders |

| Diameter | 0.4 to 3 nm | 5 to 50 nm |

| Electrical Conductivity | Excellent; can be metallic or semiconducting | Good; primarily metallic behavior |

| Mechanical Strength | Very high tensile strength (~100 GPa) | High, but generally less than SWCNT |

| Thermal Conductivity | Up to 3500 W/m*K | Up to 3000 W/m*K |

| Purity and Defects | More prone to defects during synthesis | More robust and easier to synthesize |

| Cost | Higher due to complex synthesis | Lower, simpler production process |

| Applications | Electronics, sensors, nanoelectronics, drug delivery | Composites, energy storage, structural reinforcement |

Introduction to Carbon Nanotubes

Single-walled carbon nanotubes (SWCNTs) consist of a single graphene sheet rolled into a cylindrical shape with diameters typically around 1 nanometer, offering exceptional electrical conductivity and mechanical strength. Multi-walled carbon nanotubes (MWCNTs) are composed of multiple concentric graphene cylinders, resulting in larger diameters ranging from 5 to 50 nanometers and enhanced structural stability. Both SWCNTs and MWCNTs exhibit unique properties useful in nanotechnology, electronics, and materials science, with applications defined by their distinct morphologies and electrical characteristics.

Structural Differences: SWCNT vs MWCNT

Single-walled carbon nanotubes (SWCNTs) consist of a single graphene sheet rolled into a cylindrical shape with diameters typically around 0.7 to 2 nanometers. Multi-walled carbon nanotubes (MWCNTs) are composed of multiple concentric graphene cylinders with interlayer spacing close to 0.34 nanometers, resulting in larger diameters ranging from 2 to over 100 nanometers. The structural differences impact their mechanical strength, electrical conductivity, and chemical reactivity, with SWCNTs exhibiting more uniform properties due to their single-layer configuration.

Synthesis Methods for SWCNT and MWCNT

Single-walled carbon nanotubes (SWCNTs) are primarily synthesized using methods such as chemical vapor deposition (CVD), arc discharge, and laser ablation, which facilitate the formation of uniform, single-layer graphene cylinders. Multi-walled carbon nanotubes (MWCNTs) are commonly produced via arc discharge, CVD, and carbon arc techniques, promoting the growth of multiple concentric graphene layers. The choice of catalyst, temperature, and carbon feedstock critically influences the yield and structural quality of both SWCNTs and MWCNTs during synthesis.

Mechanical Properties Comparison

Single-walled carbon nanotubes (SWCNTs) exhibit superior tensile strength and elasticity due to their seamless cylindrical structure, reaching up to 63 GPa in tensile strength and 1 TPa in Young's modulus. Multi-walled carbon nanotubes (MWCNTs), composed of multiple concentric graphene layers, provide enhanced structural stability and higher resistance to bending and compression, with tensile strength typically ranging from 10 to 30 GPa. The interlayer van der Waals interactions in MWCNTs contribute to improved load transfer and durability under mechanical stress, making them suitable for composite reinforcement applications.

Electrical Properties: Conductivity and Applications

Single-walled carbon nanotubes (SWCNTs) exhibit superior electrical conductivity due to their seamless cylindrical structure, enabling ballistic electron transport ideal for nanoelectronics and high-performance sensors. Multi-walled carbon nanotubes (MWCNTs) have lower conductivity because of interlayer interactions and defects but offer enhanced mechanical strength, making them suitable for conductive composites and electromagnetic interference shielding. Both types serve critical roles in flexible electronics, energy storage devices, and advanced conductive materials depending on specific electrical performance requirements.

Thermal Conductivity: Performance and Usage

Single-walled carbon nanotubes (SWCNTs) exhibit exceptional thermal conductivity, typically measuring around 3500 W/mK, making them highly efficient for heat dissipation in nanoelectronics and thermal interface materials. Multi-walled carbon nanotubes (MWCNTs) have lower thermal conductivity, approximately 3000 W/mK, due to interlayer interactions and defects, which affect phonon transport. The superior thermal performance of SWCNTs favors applications requiring rapid heat transfer, while MWCNTs offer durability and cost advantages in composite materials with moderate thermal management needs.

Purity and Defect Analysis

Single-walled carbon nanotubes (SWCNTs) typically exhibit higher purity levels due to their simpler structure, facilitating fewer defects and more consistent electrical properties. Multi-walled carbon nanotubes (MWCNTs) contain multiple concentric graphene layers, which increase the likelihood of defects such as vacancies, dislocations, and amorphous carbon residues, complicating defect analysis. Advanced characterization techniques like Raman spectroscopy and transmission electron microscopy (TEM) are essential for accurately assessing purity and identifying structural defects in both SWCNTs and MWCNTs.

Cost and Scalability Considerations

Single-walled carbon nanotubes (SWCNTs) generally have higher production costs due to complex synthesis processes requiring precise control over catalyst and growth conditions, limiting large-scale manufacturing. Multi-walled carbon nanotubes (MWCNTs) offer more cost-effective and scalable production methods, such as chemical vapor deposition, enabling mass production with consistent quality. The scalability advantage of MWCNTs makes them more commercially viable for applications requiring bulk quantities, despite SWCNTs' superior electrical and mechanical properties.

Application Areas: SWCNT vs MWCNT

Single-walled carbon nanotubes (SWCNTs) find extensive applications in nanoelectronics, sensors, and energy storage due to their exceptional electrical conductivity and mechanical strength. Multi-walled carbon nanotubes (MWCNTs) are widely used in composite materials, conductive films, and structural reinforcement because of their superior mechanical stability and cost-effectiveness. Both SWCNTs and MWCNTs contribute significantly to advancements in biomedical devices and environmental remediation technologies.

Future Prospects and Research Directions

Single-walled carbon nanotubes (SWCNTs) exhibit exceptional electron mobility and mechanical strength, making them ideal for future applications in nanoelectronics and high-performance composite materials. Multi-walled carbon nanotubes (MWCNTs) offer enhanced structural stability and easier mass production, positioning them as key candidates for energy storage and environmental remediation technologies. Emerging research emphasizes hybrid nanotube architectures and functionalization techniques to optimize conductivity, durability, and scalability for next-generation electronic devices and sustainable materials.

Single-walled carbon nanotube vs Multi-walled carbon nanotube Infographic

materialdif.com

materialdif.com