Unidirectional carbon fiber offers superior strength and stiffness along a single axis, making it ideal for applications requiring high tensile strength in one direction. Woven carbon fiber provides more balanced mechanical properties with enhanced impact resistance and torsional strength due to its interlaced fiber pattern. Selecting between unidirectional and woven carbon fiber depends on the specific structural demands and load conditions of the project.

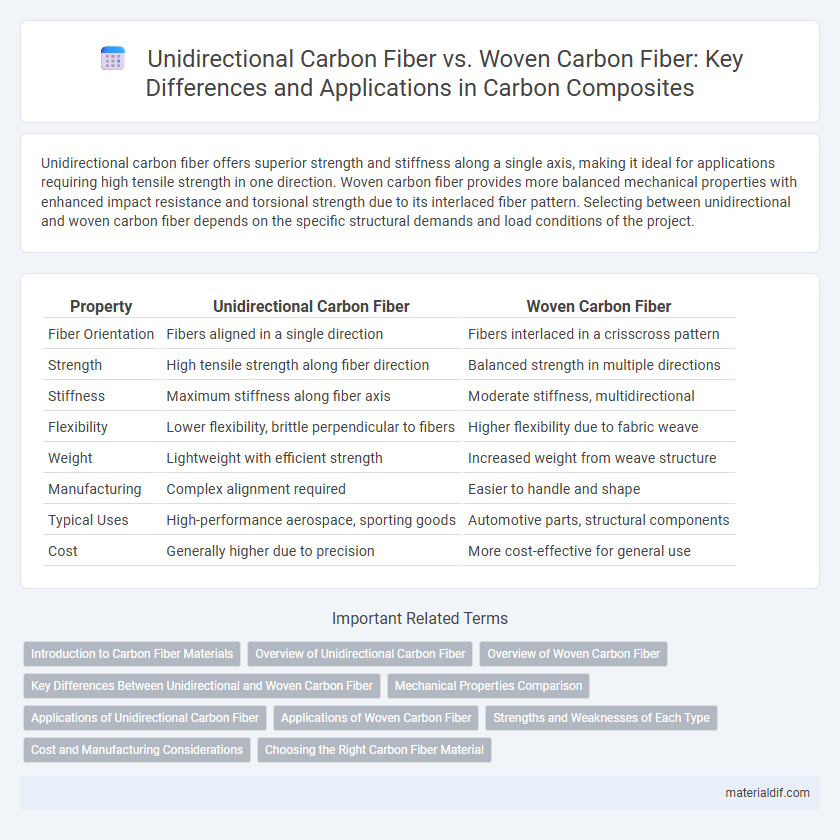

Table of Comparison

| Property | Unidirectional Carbon Fiber | Woven Carbon Fiber |

|---|---|---|

| Fiber Orientation | Fibers aligned in a single direction | Fibers interlaced in a crisscross pattern |

| Strength | High tensile strength along fiber direction | Balanced strength in multiple directions |

| Stiffness | Maximum stiffness along fiber axis | Moderate stiffness, multidirectional |

| Flexibility | Lower flexibility, brittle perpendicular to fibers | Higher flexibility due to fabric weave |

| Weight | Lightweight with efficient strength | Increased weight from weave structure |

| Manufacturing | Complex alignment required | Easier to handle and shape |

| Typical Uses | High-performance aerospace, sporting goods | Automotive parts, structural components |

| Cost | Generally higher due to precision | More cost-effective for general use |

Introduction to Carbon Fiber Materials

Unidirectional carbon fiber consists of fibers aligned in a single direction, providing exceptional tensile strength and stiffness along that axis, making it ideal for high-performance aerospace and automotive applications requiring precise load management. Woven carbon fiber features fibers interlaced at right angles, offering enhanced multidirectional strength, improved impact resistance, and dimensional stability suited for complex structural components. Understanding the differences in fiber orientation and mechanical properties between unidirectional and woven carbon fibers is essential for optimizing composite material selection in engineering designs.

Overview of Unidirectional Carbon Fiber

Unidirectional carbon fiber consists of fibers aligned in a single direction, providing maximum strength and stiffness along that axis. This configuration is ideal for applications requiring high tensile strength and rigidity, such as aerospace components and high-performance sporting goods. Its anisotropic properties make it less flexible but more efficient in load-bearing along the fiber direction compared to woven carbon fiber.

Overview of Woven Carbon Fiber

Woven carbon fiber consists of interlaced fibers arranged in a crisscross pattern, enhancing its multidirectional strength and flexibility compared to unidirectional carbon fiber. This fabric format offers superior impact resistance and improved damage tolerance, making it ideal for complex shapes and dynamic loads in automotive, aerospace, and sporting goods applications. The balanced mechanical properties of woven carbon fiber provide a reliable combination of stiffness and toughness, essential for high-performance composite structures.

Key Differences Between Unidirectional and Woven Carbon Fiber

Unidirectional carbon fiber features fibers aligned in a single direction, offering maximum strength and stiffness along the fiber axis, making it ideal for applications requiring high tensile strength in one direction. Woven carbon fiber consists of interlaced fibers in multiple directions, providing greater flexibility, impact resistance, and dimensional stability, suitable for complex shapes and multi-directional load-bearing. The key differences lie in their mechanical properties and structural behavior, with unidirectional fiber optimizing strength in specific directions while woven fiber balances strength and durability across various axes.

Mechanical Properties Comparison

Unidirectional carbon fiber offers superior tensile strength and stiffness along a single axis, making it ideal for load-bearing applications requiring maximum strength in one direction. Woven carbon fiber provides enhanced multidirectional strength and improved impact resistance due to its interlaced structure, offering better durability under complex loading conditions. Tensile modulus for unidirectional fibers typically ranges from 230 to 600 GPa, while woven composites deliver balanced mechanical properties with slightly lower tensile strength but greater flexibility and damage tolerance.

Applications of Unidirectional Carbon Fiber

Unidirectional carbon fiber exhibits exceptional tensile strength and stiffness along a single axis, making it ideal for aerospace components, high-performance sporting goods, and automotive parts where precise load direction is critical. Its alignment enhances structural efficiency in wind turbine blades, prosthetics, and racing bicycles, optimizing weight-to-strength ratios. Industries leverage unidirectional carbon fiber to achieve superior performance in applications requiring maximal strength in specific orientations.

Applications of Woven Carbon Fiber

Woven carbon fiber is widely used in aerospace, automotive, and sporting goods industries due to its superior impact resistance and flexibility compared to unidirectional carbon fiber. Its bidirectional weave allows for enhanced strength in multiple directions, making it ideal for components subjected to complex stress patterns such as aircraft fuselage panels and high-performance car body parts. Woven carbon fiber's ability to maintain structural integrity while providing a lightweight solution drives its adoption in advanced composite manufacturing.

Strengths and Weaknesses of Each Type

Unidirectional carbon fiber offers superior tensile strength and stiffness along the fiber direction, making it ideal for applications requiring maximum load-bearing capacity in one direction, but it lacks multi-directional strength and can be prone to delamination. Woven carbon fiber provides balanced strength and enhanced impact resistance in multiple directions due to its interlaced fiber structure, though it generally has lower tensile strength and stiffness compared to unidirectional fibers. Choosing between unidirectional and woven carbon fiber depends on specific load requirements and structural demands, balancing directional strength versus durability and flexibility.

Cost and Manufacturing Considerations

Unidirectional carbon fiber offers superior strength-to-weight ratios and streamlined manufacturing processes, making it cost-effective for high-performance applications that require precise load-bearing capabilities. Woven carbon fiber, although generally more expensive due to complex weaving techniques and slower production rates, provides enhanced durability and impact resistance suited for aerospace and automotive components. Manufacturing with unidirectional fibers involves simpler layup procedures, while woven fabrics demand specialized handling and quality control to maintain consistent fiber alignment and structural integrity.

Choosing the Right Carbon Fiber Material

Unidirectional carbon fiber offers superior tensile strength along a single axis, making it ideal for applications requiring maximum stiffness and strength in a specific direction. Woven carbon fiber provides multidirectional strength and enhanced impact resistance due to its interlaced fiber architecture, making it suitable for complex shapes and load scenarios. Selecting the right carbon fiber material depends on the structural requirements, load distribution, and manufacturing process of the end product.

Unidirectional carbon fiber vs Woven carbon fiber Infographic

materialdif.com

materialdif.com