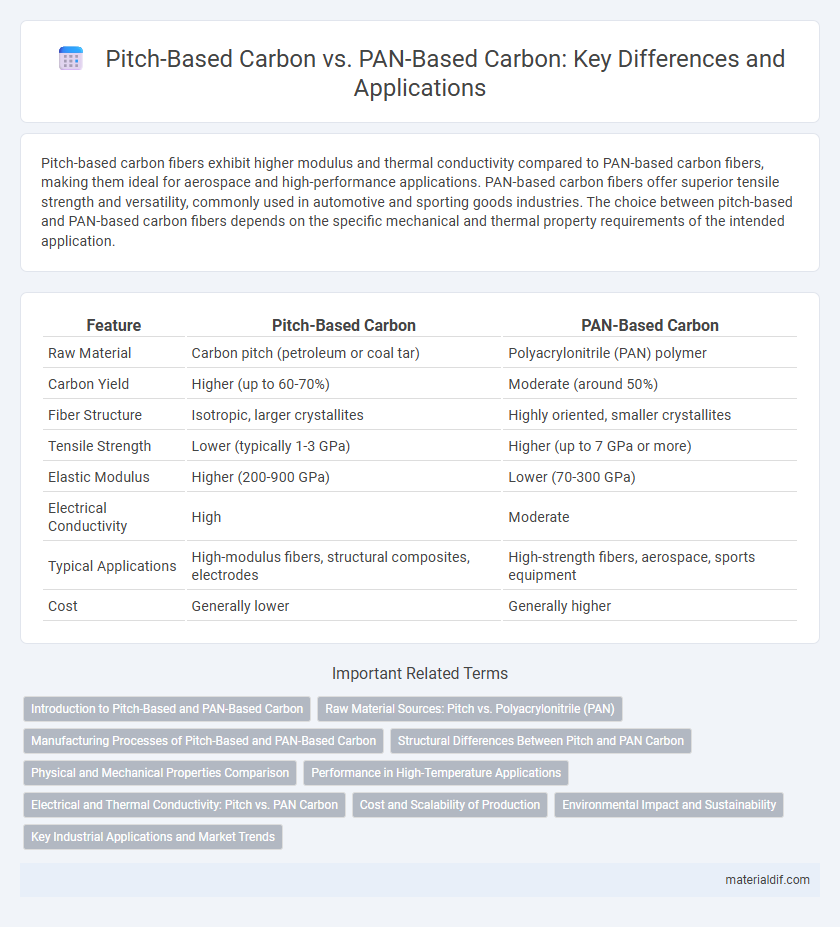

Pitch-based carbon fibers exhibit higher modulus and thermal conductivity compared to PAN-based carbon fibers, making them ideal for aerospace and high-performance applications. PAN-based carbon fibers offer superior tensile strength and versatility, commonly used in automotive and sporting goods industries. The choice between pitch-based and PAN-based carbon fibers depends on the specific mechanical and thermal property requirements of the intended application.

Table of Comparison

| Feature | Pitch-Based Carbon | PAN-Based Carbon |

|---|---|---|

| Raw Material | Carbon pitch (petroleum or coal tar) | Polyacrylonitrile (PAN) polymer |

| Carbon Yield | Higher (up to 60-70%) | Moderate (around 50%) |

| Fiber Structure | Isotropic, larger crystallites | Highly oriented, smaller crystallites |

| Tensile Strength | Lower (typically 1-3 GPa) | Higher (up to 7 GPa or more) |

| Elastic Modulus | Higher (200-900 GPa) | Lower (70-300 GPa) |

| Electrical Conductivity | High | Moderate |

| Typical Applications | High-modulus fibers, structural composites, electrodes | High-strength fibers, aerospace, sports equipment |

| Cost | Generally lower | Generally higher |

Introduction to Pitch-Based and PAN-Based Carbon

Pitch-based carbon fibers derive from petroleum or coal tar pitch, characterized by their high carbon yield and excellent thermal conductivity, making them ideal for high-temperature applications. PAN-based carbon fibers originate from polyacrylonitrile (PAN) precursors and offer superior tensile strength and modulus, widely used in aerospace and automotive industries. Both types undergo carbonization but differ significantly in microstructure and performance properties, influencing their suitability for specific industrial uses.

Raw Material Sources: Pitch vs. Polyacrylonitrile (PAN)

Pitch-based carbon fibers originate from coal tar or petroleum pitch, offering high carbon yield and excellent thermal stability due to their aromatic hydrocarbon structure. PAN-based carbon fibers derive from polyacrylonitrile, a synthetic polymer that provides superior mechanical properties and tensile strength through its molecular alignment during carbonization. The choice between pitch and PAN as raw materials significantly influences fiber morphology, performance characteristics, and applications in aerospace, automotive, and structural composites.

Manufacturing Processes of Pitch-Based and PAN-Based Carbon

Pitch-based carbon is produced by carbonizing pitch, a complex mixture of polycyclic aromatic hydrocarbons derived mainly from petroleum or coal tar, involving a gradual heating process up to 1000-1500degC to remove volatile components and stabilize the carbon structure. PAN-based carbon fibers originate from polyacrylonitrile precursors, undergoing stabilization at 200-300degC in an oxidizing atmosphere, followed by carbonization at 1000-1600degC to convert the polymer chain into a crystalline graphite structure. The manufacturing of pitch-based carbon emphasizes the thermal treatment of pitch to achieve a high degree of graphitization, whereas PAN-based carbon involves precise chemical stabilization and controlled heating to develop tensile strength and structural integrity.

Structural Differences Between Pitch and PAN Carbon

Pitch-based carbon fibers possess a more ordered, graphitic structure with larger crystallite sizes, contributing to higher modulus and thermal conductivity compared to PAN-based carbon fibers. PAN-based carbon fibers exhibit a turbostratic structure characterized by smaller, less ordered graphitic domains, which enhances tensile strength and toughness. The distinct microstructures impact mechanical properties, making pitch-based fibers suitable for high-stiffness applications, whereas PAN-based fibers excel in strength-driven uses.

Physical and Mechanical Properties Comparison

Pitch-based carbon fibers exhibit higher modulus and density compared to PAN-based carbon fibers due to their more graphitic microstructure, resulting in superior stiffness and thermal conductivity. PAN-based carbon fibers generally provide better tensile strength and elongation at break, making them more suitable for applications requiring toughness and flexibility. The distinct manufacturing processes lead to variations in crystallinity and fiber morphology, directly influencing their mechanical performance and suitability for different industrial uses.

Performance in High-Temperature Applications

Pitch-based carbon fibers exhibit superior thermal stability and higher modulus compared to PAN-based carbon fibers, making them more suitable for high-temperature applications exceeding 3000degC. Their graphitic structure allows better retention of mechanical properties under extreme heat, while PAN-based fibers, with amorphous carbon content, tend to degrade faster at elevated temperatures. Consequently, pitch-based carbon fibers are preferred in aerospace components and high-temperature composites requiring excellent thermal resistance and dimensional stability.

Electrical and Thermal Conductivity: Pitch vs. PAN Carbon

Pitch-based carbon fibers exhibit superior electrical and thermal conductivity compared to PAN-based carbon fibers due to their higher degree of graphitization and larger crystal size. The ordered structure of pitch carbon enhances electron mobility and phonon transfer, resulting in conductivity values reaching up to 1000 S/cm electrically and thermal conductivity exceeding 400 W/mK. In contrast, PAN-based carbon fibers typically show lower conductivity, around 200-500 S/cm electrically and 100-200 W/mK thermally, due to their less graphitic and more amorphous microstructure.

Cost and Scalability of Production

Pitch-based carbon fibers generally offer lower production costs due to the abundance and lower price of pitch raw materials compared to PAN (polyacrylonitrile). PAN-based carbon fibers, while more expensive, benefit from well-established large-scale manufacturing processes that enable consistent quality and scalability for high-performance applications. The choice between pitch-based and PAN-based carbon fibers hinges on balancing cost-effectiveness with the required mechanical properties and production volume.

Environmental Impact and Sustainability

Pitch-based carbon fibers exhibit a lower environmental footprint compared to PAN-based carbon fibers due to their utilization of coal tar or petroleum pitch, which are by-products of fossil fuel processing, enabling more efficient resource use and reduced raw material extraction. PAN-based carbon fibers involve energy-intensive stabilization and carbonization steps, contributing to higher greenhouse gas emissions and greater energy consumption throughout their lifecycle. Sustainable alternatives are being explored to improve the recyclability and ecological impacts of both fiber types, with research focusing on bio-based precursors and circular manufacturing processes.

Key Industrial Applications and Market Trends

Pitch-based carbon fibers exhibit superior thermal conductivity and high modulus, making them ideal for aerospace and defense applications requiring lightweight, high-strength materials. PAN-based carbon fibers dominate the automotive and sporting goods sectors due to their balanced tensile strength, cost-effectiveness, and versatility in composite manufacturing. Market trends indicate increasing demand for pitch-based carbon in high-performance industries and growing adoption of PAN-based carbon fibers in mass production, driven by advancements in manufacturing processes and carbon fiber recycling initiatives.

Pitch-based carbon vs PAN-based carbon Infographic

materialdif.com

materialdif.com