Primary shaped carbon refers to carbon materials formed directly from raw carbonaceous substances through processes like carbonization and graphitization, resulting in high purity and structural integrity. Secondary shaped carbon is produced by reworking or molding existing carbon materials, which may introduce impurities but allows for more complex shapes and customization. Both types are crucial in industries requiring specific mechanical and chemical properties tailored to applications such as electrodes, filters, and composite materials.

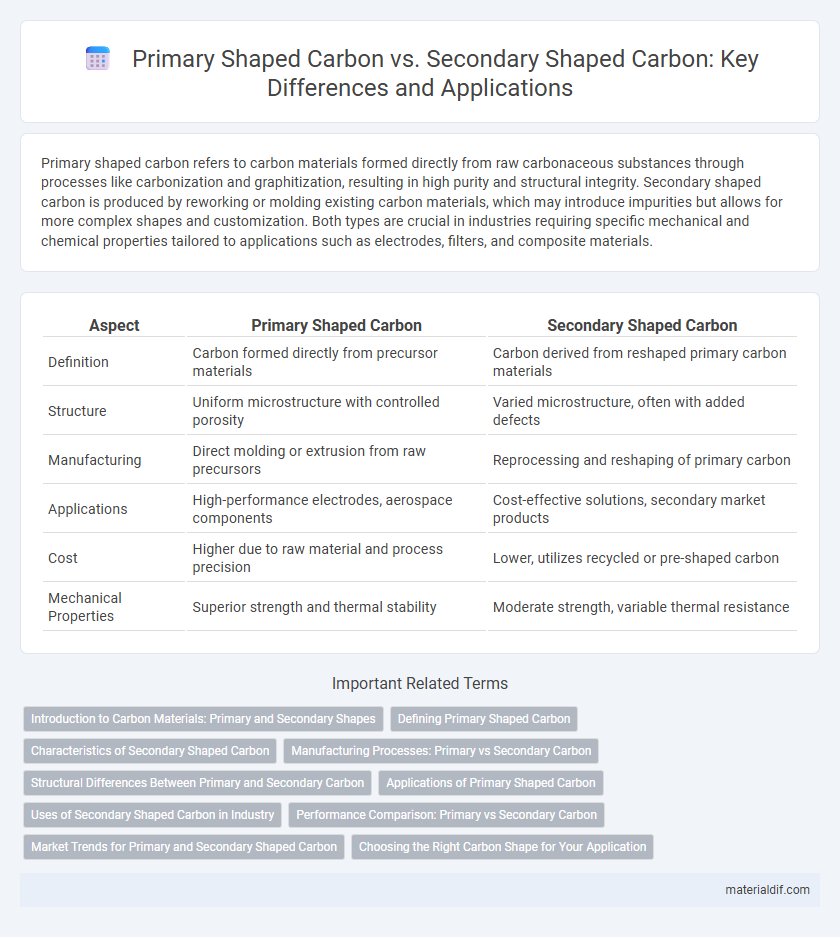

Table of Comparison

| Aspect | Primary Shaped Carbon | Secondary Shaped Carbon |

|---|---|---|

| Definition | Carbon formed directly from precursor materials | Carbon derived from reshaped primary carbon materials |

| Structure | Uniform microstructure with controlled porosity | Varied microstructure, often with added defects |

| Manufacturing | Direct molding or extrusion from raw precursors | Reprocessing and reshaping of primary carbon |

| Applications | High-performance electrodes, aerospace components | Cost-effective solutions, secondary market products |

| Cost | Higher due to raw material and process precision | Lower, utilizes recycled or pre-shaped carbon |

| Mechanical Properties | Superior strength and thermal stability | Moderate strength, variable thermal resistance |

Introduction to Carbon Materials: Primary and Secondary Shapes

Primary shaped carbon refers to carbon materials formed directly through processes like casting or molding, resulting in initial structural configurations such as rods, blocks, or powders. Secondary shaped carbon involves further processing of primary forms through machining, cutting, or sintering to achieve complex geometries and enhanced mechanical properties. Understanding the distinction between primary and secondary shaped carbon is crucial for tailoring material characteristics in applications ranging from electrodes to structural components.

Defining Primary Shaped Carbon

Primary shaped carbon refers to carbon materials derived directly from natural sources such as coal or petroleum through controlled pyrolysis, resulting in distinct morphologies like flakes or spheres. Its structure largely influences key properties including surface area, porosity, and purity, which determine performance in applications such as energy storage and filtration. Unlike secondary shaped carbon, which is manufactured by reprocessing primary carbon into engineered forms, primary shaped carbon maintains the inherent characteristics of its raw material.

Characteristics of Secondary Shaped Carbon

Secondary shaped carbon exhibits enhanced structural uniformity and increased surface area compared to primary shaped carbon, resulting from processes like pulverization and milling. Its improved porosity facilitates superior adsorption and filtration capabilities, essential for industrial applications such as water purification and air treatment. Compared to primary shaped carbon, secondary shaped carbon often features smaller particle sizes and more consistent shapes, optimizing its reactivity and integration into composite materials.

Manufacturing Processes: Primary vs Secondary Carbon

Primary shaped carbon is produced directly from carbonaceous raw materials such as coal tar pitch or petroleum coke through high-temperature carbonization and graphitization processes, ensuring high purity and controlled microstructure. Secondary shaped carbon derives from recycled carbon materials, which undergo reprocessing steps including crushing, screening, and recarbonization, often resulting in lower uniformity and variable performance characteristics. Manufacturing processes for primary carbon emphasize precise thermal treatment and raw material selection, while secondary carbon relies heavily on resource recovery and material reconstitution techniques.

Structural Differences Between Primary and Secondary Carbon

Primary shaped carbon atoms are bonded to only one other carbon atom, resulting in a simpler, linear structure, often found in alkanes like methane. Secondary shaped carbon atoms are connected to two other carbon atoms, creating a more complex and branched framework typical in molecules such as ethane. These structural differences influence the carbon's chemical reactivity, stability, and physical properties in organic compounds.

Applications of Primary Shaped Carbon

Primary shaped carbon is essential for applications requiring high purity and uniform particle size, such as in batteries, electrodes, and advanced composites. Its controlled morphology improves conductivity and mechanical properties, making it ideal in energy storage, aerospace, and electronics industries. The precision in shaping primary carbon enhances performance and reliability in critical manufacturing processes.

Uses of Secondary Shaped Carbon in Industry

Secondary shaped carbon is extensively utilized in industries for its enhanced structural properties and tailored shapes, making it ideal for manufacturing electrodes in electric arc furnaces and components in aerospace engineering. Its precise form and improved density contribute to efficient conductivity and thermal resistance, crucial in steel production and battery technology. The versatility of secondary shaped carbon supports advanced applications in automotive, chemical processing, and energy storage sectors.

Performance Comparison: Primary vs Secondary Carbon

Primary shaped carbon exhibits superior mechanical strength and electrical conductivity due to its chemically bonded crystalline structure, making it ideal for high-performance applications such as aerospace and automotive components. Secondary shaped carbon, formed from reprocessed or recycled carbon materials, offers cost efficiency and environmental benefits but typically shows reduced tensile strength and thermal stability compared to primary carbon. Performance comparisons highlight that while primary carbon ensures enhanced durability and reliability, secondary carbon suits less demanding applications where sustainability and cost reduction are prioritized.

Market Trends for Primary and Secondary Shaped Carbon

The market for Primary Shaped Carbon is experiencing robust growth driven by increasing demand in tire manufacturing and rubber applications, where high purity and consistent particle size are critical. Secondary Shaped Carbon markets are expanding due to their cost-effectiveness and use in industrial applications such as plastics, inks, and coatings, benefiting from advancements in recycling and processing technologies. Forecasts indicate that Primary Shaped Carbon will maintain a higher growth rate due to stringent quality requirements, while Secondary Shaped Carbon will see steady demand influenced by evolving industrial uses and sustainability trends.

Choosing the Right Carbon Shape for Your Application

Primary shaped carbon offers superior structural integrity and thermal conductivity, making it ideal for high-performance industrial applications such as aerospace and automotive components. Secondary shaped carbon, often derived from recycled or modified sources, provides cost-effective solutions suitable for less demanding uses like consumer products and insulation materials. Selecting the right carbon shape depends on application requirements including strength, thermal properties, and budget constraints.

Primary Shaped Carbon vs Secondary Shaped Carbon Infographic

materialdif.com

materialdif.com