Carbon fiber weave offers multidirectional strength and enhanced durability due to its interlaced pattern, making it ideal for applications requiring balanced performance and resistance to impact. Carbon fiber unidirectional fibers align in a single direction, providing superior tensile strength and stiffness along that axis, which benefits components subjected to consistent directional loads. Choosing between the two types depends on the specific structural demands and desired mechanical properties in carbon PET manufacturing.

Table of Comparison

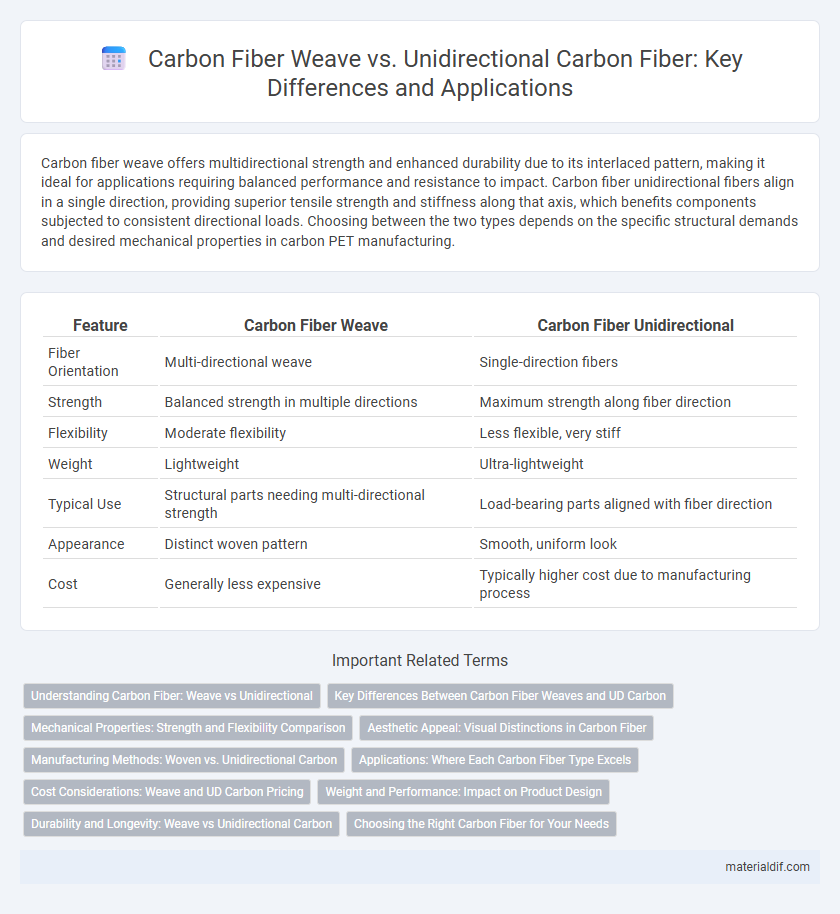

| Feature | Carbon Fiber Weave | Carbon Fiber Unidirectional |

|---|---|---|

| Fiber Orientation | Multi-directional weave | Single-direction fibers |

| Strength | Balanced strength in multiple directions | Maximum strength along fiber direction |

| Flexibility | Moderate flexibility | Less flexible, very stiff |

| Weight | Lightweight | Ultra-lightweight |

| Typical Use | Structural parts needing multi-directional strength | Load-bearing parts aligned with fiber direction |

| Appearance | Distinct woven pattern | Smooth, uniform look |

| Cost | Generally less expensive | Typically higher cost due to manufacturing process |

Understanding Carbon Fiber: Weave vs Unidirectional

Carbon fiber weave features interlaced fibers providing multidirectional strength and enhanced durability, making it ideal for complex shapes and impact resistance. Unidirectional carbon fiber aligns all fibers parallel, offering superior tensile strength and stiffness along a single axis, optimal for weight-critical, linear load applications. Choosing between weave and unidirectional depends on balancing structural demands, flexibility, and load orientation in carbon fiber composite design.

Key Differences Between Carbon Fiber Weaves and UD Carbon

Carbon fiber weave features interlaced fibers that provide enhanced multidirectional strength and flexibility, making it ideal for applications requiring robust structural integrity and impact resistance. Unidirectional (UD) carbon fiber consists of fibers aligned in a single direction, delivering superior tensile strength and stiffness along that axis but less resistance to forces from other angles. These key differences influence material selection based on performance requirements such as load distribution, weight optimization, and manufacturing processes.

Mechanical Properties: Strength and Flexibility Comparison

Carbon fiber weave offers a balanced combination of strength and flexibility due to its interlaced fiber structure, providing multidirectional load resistance and impact durability. Unidirectional carbon fiber exhibits superior tensile strength and stiffness along the fiber axis but lacks flexibility and shear resistance in perpendicular directions. Engineers often select woven carbon fiber for applications requiring toughness and energy absorption, while unidirectional fibers are preferred for maximum strength-to-weight ratio along a single load path.

Aesthetic Appeal: Visual Distinctions in Carbon Fiber

Carbon fiber weave features an interlaced pattern creating a distinctive checkerboard or basket-like visual texture that highlights craftsmanship and complexity. In contrast, carbon fiber unidirectional displays parallel fibers aligned in a single direction, offering a sleek, uniform appearance emphasizing strength and precision. The aesthetic appeal of woven carbon fiber is often favored for its depth and intricacy, while unidirectional carbon fiber is chosen for minimalist, high-performance designs.

Manufacturing Methods: Woven vs. Unidirectional Carbon

Woven carbon fiber involves intertwining multiple fiber strands in a crisscross pattern, providing enhanced strength and torsional rigidity ideal for complex shapes and multi-directional stress. Unidirectional carbon fiber aligns all fibers parallel in a single direction, maximizing tensile strength and stiffness along that axis, making it optimal for aerospace and high-performance automotive components. Manufacturing methods differ significantly, with woven fabrics requiring precise loom weaving and layering, while unidirectional fibers are laid in continuous sheets or pre-preg tapes for controlled fiber orientation and thickness.

Applications: Where Each Carbon Fiber Type Excels

Carbon fiber weave offers enhanced multi-directional strength and is ideal for applications requiring durability and impact resistance, such as automotive body panels and sports equipment. Carbon fiber unidirectional excels in applications demanding maximum tensile strength and stiffness in a single direction, like aerospace components and high-performance bike frames. Choosing between woven and unidirectional carbon fiber depends on load distribution needs and the specific mechanical properties required for the application.

Cost Considerations: Weave and UD Carbon Pricing

Carbon fiber weave typically incurs higher costs due to the complex manufacturing process required to interlace the fibers, resulting in increased labor and material expenses compared to unidirectional (UD) carbon fiber. UD carbon fiber offers cost advantages with its simpler, linear fiber alignment and more efficient production methods, making it a preferred choice for budget-sensitive applications. Price differences between carbon fiber weave and UD carbon fiber directly influence material selection decisions in industries such as aerospace, automotive, and sporting goods.

Weight and Performance: Impact on Product Design

Carbon fiber weave offers a balanced combination of weight and multidirectional strength, enhancing product durability without significant weight increase, making it ideal for complex load-bearing designs. Unidirectional carbon fiber provides superior strength and stiffness along a single axis with minimal weight, optimizing performance in applications where directional loads dominate. Designers prioritize unidirectional carbon fiber for lightweight, high-performance parts while selecting woven carbon fiber when multidirectional strength and structural integrity are critical.

Durability and Longevity: Weave vs Unidirectional Carbon

Carbon fiber weave exhibits superior durability due to its interlaced fibers that provide multidirectional strength, enhancing resistance to impact and fatigue. Unidirectional carbon fiber offers exceptional strength along a single axis but lacks the cross-directional reinforcement, making it more susceptible to damage under multi-directional stresses. Longevity of woven carbon fiber typically surpasses unidirectional variants in applications requiring consistent load-bearing in various directions, maintaining structural integrity over extended periods.

Choosing the Right Carbon Fiber for Your Needs

Carbon fiber weave offers multidirectional strength and enhanced impact resistance, making it ideal for applications requiring durability and aesthetic appeal, such as automotive panels and sports equipment. Carbon fiber unidirectional provides superior tensile strength along a single axis, optimal for structural components like aerospace parts and high-performance sporting goods where stiffness and weight reduction are critical. Selecting the right carbon fiber depends on balancing mechanical requirements, load directions, and environmental factors to ensure maximum performance and longevity.

Carbon Fiber Weave vs Carbon Fiber Unidirectional Infographic

materialdif.com

materialdif.com