Carbon black is a fine black powder produced by incomplete combustion of heavy petroleum products, primarily used as a reinforcing filler in tires and rubber products due to its high durability and conductivity. Carbon white, or white carbon, commonly refers to silica or titanium dioxide, which serve as additives to improve brightness, opacity, and wear resistance in plastics and paints. Understanding the distinct properties of carbon black and carbon white is essential for optimizing material performance in industrial applications.

Table of Comparison

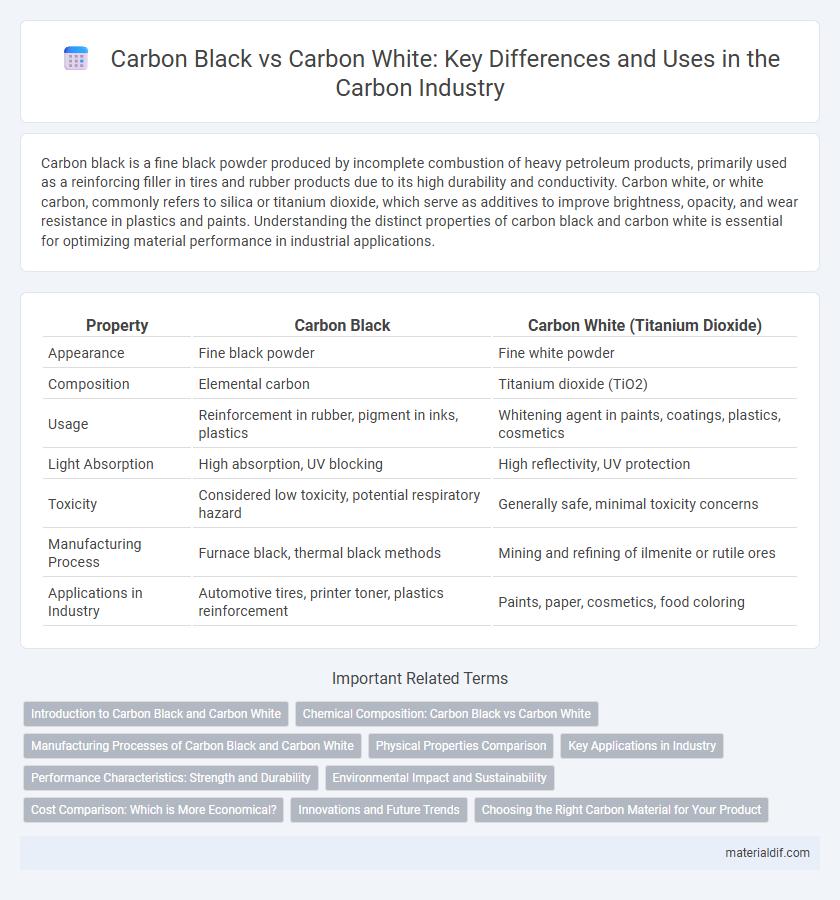

| Property | Carbon Black | Carbon White (Titanium Dioxide) |

|---|---|---|

| Appearance | Fine black powder | Fine white powder |

| Composition | Elemental carbon | Titanium dioxide (TiO2) |

| Usage | Reinforcement in rubber, pigment in inks, plastics | Whitening agent in paints, coatings, plastics, cosmetics |

| Light Absorption | High absorption, UV blocking | High reflectivity, UV protection |

| Toxicity | Considered low toxicity, potential respiratory hazard | Generally safe, minimal toxicity concerns |

| Manufacturing Process | Furnace black, thermal black methods | Mining and refining of ilmenite or rutile ores |

| Applications in Industry | Automotive tires, printer toner, plastics reinforcement | Paints, paper, cosmetics, food coloring |

Introduction to Carbon Black and Carbon White

Carbon black is a fine black powder produced by the incomplete combustion of heavy petroleum products, widely used as a reinforcing filler in tires and other rubber products due to its excellent durability and conductivity. Carbon white, also known as precipitated silica, is a white, porous powder derived from sodium silicate and sulfuric acid, primarily utilized as a filler in rubber and plastics to enhance strength and abrasion resistance. Both materials play crucial roles in industrial applications, with carbon black dominating the pigment and conductivity sectors and carbon white excelling in reinforcing and reinforcing filler roles.

Chemical Composition: Carbon Black vs Carbon White

Carbon black consists primarily of elemental carbon with a high structure of fused carbon particles, while carbon white, often referring to titanium dioxide, is a compound composed mainly of titanium and oxygen atoms. Carbon black is produced through the incomplete combustion of hydrocarbons, resulting in amorphous carbon particles, whereas carbon white is synthesized from mineral ores and exhibits a crystalline structure. The distinct chemical compositions lead to different properties, with carbon black acting as a reinforcing filler in rubber and pigments, and carbon white serving as a bright, opaque white pigment in paints and coatings.

Manufacturing Processes of Carbon Black and Carbon White

Carbon black is produced primarily through the incomplete combustion of heavy petroleum products like FCC tar, coal tar, or ethylene cracking tar, using processes such as furnace black, channel black, or thermal black methods. Carbon white, also known as titanium dioxide, is manufactured via the sulfate or chloride process where titanium-containing minerals undergo chemical treatment and high-temperature reactions to produce a fine white pigment. The contrasting manufacturing techniques result in carbon black's fine particulate form with high surface area, while carbon white is characterized by its pigmentary properties and whiteness.

Physical Properties Comparison

Carbon black exhibits a high surface area with fine particle size ranging from 10 to 500 nanometers and presents a deep black color due to its strong light absorption, while Carbon white, primarily composed of titanium dioxide, features larger particle sizes around 200 to 300 nanometers with a bright white appearance and excellent light scattering properties. Carbon black has a density of approximately 1.8 g/cm3, contrasting with the higher density of Carbon white, which is about 4.2 g/cm3. The differing crystallinity and surface chemistry of these two materials result in distinct thermal conductivity and electrical conductivity characteristics, with Carbon black being conductive and Carbon white generally insulating.

Key Applications in Industry

Carbon black is extensively used in rubber manufacturing, particularly in tire production, due to its reinforcing properties and UV protection, while carbon white (titanium dioxide) plays a critical role in the paint, coatings, and plastics industries by providing superior whiteness, opacity, and brightness. Carbon black also finds applications in ink formulations, plastics, and batteries for enhanced conductivity and durability. Conversely, carbon white is preferred in cosmetics, food packaging, and paper products for its non-toxic nature and excellent color retention.

Performance Characteristics: Strength and Durability

Carbon black enhances strength and durability in materials by providing excellent reinforcement, improving resistance to wear and tear, and increasing tensile strength in rubber and plastics. In contrast, carbon white, or titanium dioxide, primarily acts as a pigment and offers minimal impact on mechanical performance, resulting in lower reinforcement capabilities and durability. The superior performance characteristics of carbon black make it the preferred additive for applications requiring enhanced structural integrity and long-term resilience.

Environmental Impact and Sustainability

Carbon black, produced primarily from incomplete combustion of heavy petroleum products, has a significant environmental impact due to high energy consumption and the release of pollutants such as particulate matter and volatile organic compounds. In contrast, carbon white, often referring to titanium dioxide, exhibits lower direct environmental toxicity but involves substantial mining and chemical processing, raising concerns about resource depletion and water pollution. Sustainable alternatives focus on renewable feedstocks and cleaner production technologies to reduce the carbon footprint and ecological damage associated with both materials.

Cost Comparison: Which is More Economical?

Carbon black is generally more economical than carbon white due to its lower production costs, as it is derived from incomplete combustion of heavy petroleum products. In contrast, carbon white, primarily composed of titanium dioxide, involves more expensive processing techniques, resulting in higher pricing. Industries often favor carbon black for cost-sensitive applications like rubber reinforcement, while carbon white's higher cost is justified in premium uses such as paints and coatings for superior opacity and brightness.

Innovations and Future Trends

Carbon black continues to advance through innovations in nanoparticle synthesis and surface modification, enhancing its conductivity and durability for applications in electric vehicle tires and flexible electronics. Carbon white, particularly in the form of engineered silica and titania, is evolving with developments in photocatalytic properties and UV protection, driving growth in cosmetics and self-cleaning surfaces. Future trends indicate a convergence of these materials in hybrid composites that optimize mechanical strength and environmental sustainability for aerospace and energy storage technologies.

Choosing the Right Carbon Material for Your Product

Selecting the right carbon material depends on the desired properties and application of the product, with carbon black offering superior UV protection, conductivity, and reinforcement for rubber and plastics, while carbon white (titanium dioxide) provides excellent pigmentation, brightness, and opacity for coatings and plastics. Carbon black's nano-scale particles enhance durability and performance in tires, inks, and electronic components, whereas carbon white improves whiteness and opacity in paints, plastics, and paper products. Understanding the specific functional requirements helps optimize product quality by leveraging the distinct advantages of carbon black or carbon white in manufacturing processes.

Carbon black vs Carbon white Infographic

materialdif.com

materialdif.com