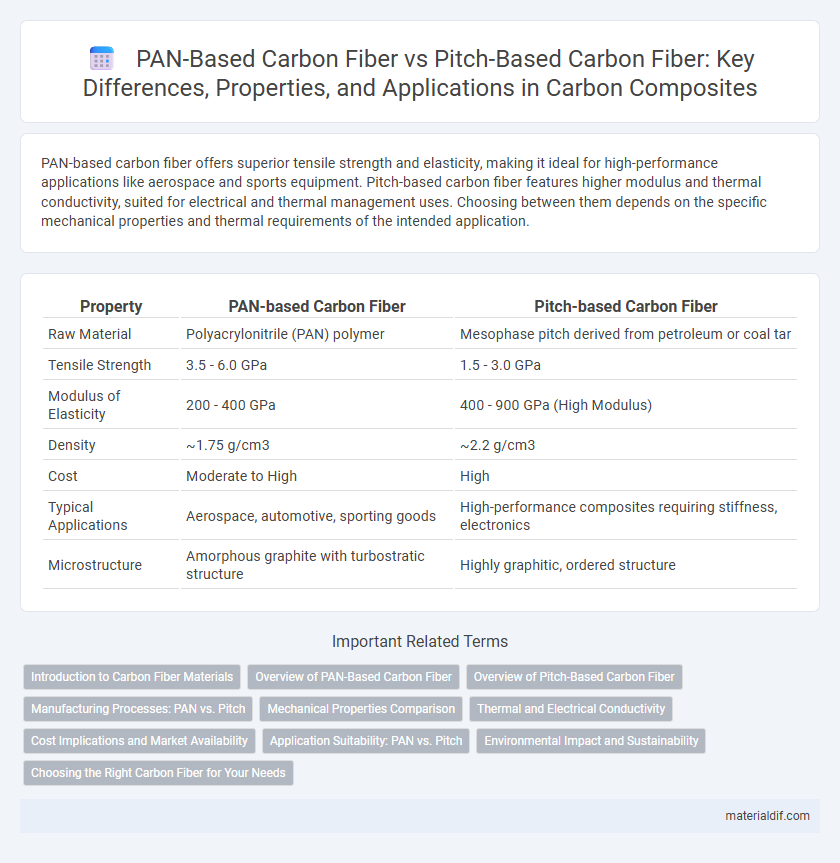

PAN-based carbon fiber offers superior tensile strength and elasticity, making it ideal for high-performance applications like aerospace and sports equipment. Pitch-based carbon fiber features higher modulus and thermal conductivity, suited for electrical and thermal management uses. Choosing between them depends on the specific mechanical properties and thermal requirements of the intended application.

Table of Comparison

| Property | PAN-based Carbon Fiber | Pitch-based Carbon Fiber |

|---|---|---|

| Raw Material | Polyacrylonitrile (PAN) polymer | Mesophase pitch derived from petroleum or coal tar |

| Tensile Strength | 3.5 - 6.0 GPa | 1.5 - 3.0 GPa |

| Modulus of Elasticity | 200 - 400 GPa | 400 - 900 GPa (High Modulus) |

| Density | ~1.75 g/cm3 | ~2.2 g/cm3 |

| Cost | Moderate to High | High |

| Typical Applications | Aerospace, automotive, sporting goods | High-performance composites requiring stiffness, electronics |

| Microstructure | Amorphous graphite with turbostratic structure | Highly graphitic, ordered structure |

Introduction to Carbon Fiber Materials

PAN-based carbon fiber, derived from polyacrylonitrile, offers high tensile strength and excellent fatigue resistance, making it ideal for aerospace and automotive applications. Pitch-based carbon fiber, produced from petroleum or coal tar pitch, provides superior thermal conductivity and modulus, suited for high-temperature environments such as heat exchangers and industrial furnaces. Both types contribute to advanced composite materials by enhancing mechanical properties and weight reduction in various industries.

Overview of PAN-Based Carbon Fiber

PAN-based carbon fiber, derived from polyacrylonitrile precursor, dominates the carbon fiber market due to its high tensile strength and modulus, making it ideal for aerospace, automotive, and sporting goods applications. This fiber undergoes stabilization, carbonization, and graphitization processes to achieve superior mechanical properties and thermal stability. PAN-based carbon fiber typically exhibits tensile strengths exceeding 3.5 GPa and modulus values above 230 GPa, outperforming pitch-based alternatives in weight-sensitive and high-performance sectors.

Overview of Pitch-Based Carbon Fiber

Pitch-based carbon fiber is derived from mesophase pitch, a liquid crystalline precursor offering high carbon yield and graphitic structure. It exhibits superior thermal stability, higher modulus, and greater electrical conductivity compared to PAN-based carbon fibers, making it ideal for aerospace and high-performance applications. The manufacturing process involves carbonization and graphitization at temperatures exceeding 2500degC, resulting in fibers with excellent stiffness and thermal resistance.

Manufacturing Processes: PAN vs. Pitch

PAN-based carbon fiber manufacturing involves stabilizing polyacrylonitrile fibers through oxidation at temperatures around 200-300degC, followed by carbonization at 1000-1500degC in an inert atmosphere, resulting in fibers with high tensile strength and moderate modulus. Pitch-based carbon fiber production starts with mesophase pitch, which undergoes melt spinning, stabilization, and carbonization at higher temperatures typically above 2000degC, yielding fibers with superior modulus and thermal conductivity. The differences in precursor materials and thermal treatment temperatures directly influence the mechanical properties and applications of PAN-based versus pitch-based carbon fibers.

Mechanical Properties Comparison

PAN-based carbon fiber exhibits higher tensile strength and better fatigue resistance compared to pitch-based carbon fiber, making it ideal for aerospace and automotive applications. Pitch-based carbon fiber offers superior modulus and stiffness, beneficial for structural components requiring rigidity and dimensional stability. The mechanical property differences arise from their distinct precursor materials and manufacturing processes, influencing fiber microstructure and performance.

Thermal and Electrical Conductivity

PAN-based carbon fiber exhibits moderate thermal conductivity, typically ranging from 10 to 20 W/m*K, while pitch-based carbon fiber can reach significantly higher values, exceeding 400 W/m*K due to its highly ordered graphitic structure. Electrically, pitch-based carbon fibers demonstrate superior conductivity, often surpassing 10,000 S/cm, compared to PAN-based fibers which usually have conductivity around 1,000 to 5,000 S/cm. These differences make pitch-based carbon fibers more suitable for applications requiring efficient heat dissipation and high electrical performance.

Cost Implications and Market Availability

PAN-based carbon fiber dominates the market due to its cost-effectiveness and widespread availability, accounting for approximately 90% of global production. Pitch-based carbon fiber, while offering superior thermal and electrical conductivity, remains significantly more expensive and is produced in much smaller quantities, limiting its accessibility to niche applications. The higher manufacturing complexity and raw material costs of pitch-based fibers result in price points that are often two to three times greater than PAN-based options, influencing industry preference toward PAN-based carbon fibers in mass-market sectors.

Application Suitability: PAN vs. Pitch

PAN-based carbon fiber excels in aerospace and automotive industries due to its high tensile strength, lightweight nature, and fatigue resistance, making it ideal for structural components and high-performance parts. Pitch-based carbon fiber offers superior thermal stability and electrical conductivity, which suits applications in electronics, thermal management, and high-temperature environments such as heat exchangers and electromagnetic shielding. Selecting between PAN and pitch-based fibers depends on whether mechanical strength or thermal/electrical properties are prioritized in the specific application.

Environmental Impact and Sustainability

PAN-based carbon fiber production consumes less energy and generates lower greenhouse gas emissions compared to pitch-based carbon fiber, making it a more sustainable option. PAN fibers are derived from polyacrylonitrile, a synthetic polymer that enables better recyclability and reduces environmental persistence. In contrast, pitch-based carbon fibers rely on petroleum pitch, resulting in higher carbon footprints and less eco-friendly disposal methods.

Choosing the Right Carbon Fiber for Your Needs

PAN-based carbon fiber offers high tensile strength and excellent fatigue resistance, making it ideal for aerospace and sporting goods applications where durability is crucial. Pitch-based carbon fiber provides superior thermal conductivity and modulus, suited for electrical and thermal management uses. Selecting the right carbon fiber depends on whether strength, stiffness, or thermal properties are the priority for your specific project.

PAN-based carbon fiber vs Pitch-based carbon fiber Infographic

materialdif.com

materialdif.com