Single-wall carbon nanotubes (SWCNTs) consist of a single layer of graphene rolled into a cylindrical shape, offering exceptional electrical conductivity, mechanical strength, and flexibility. Multi-wall carbon nanotubes (MWCNTs) are composed of multiple concentric graphene cylinders, providing enhanced structural stability and higher tensile strength but slightly lower electrical conductivity compared to SWCNTs. SWCNTs are preferred for applications requiring superior electronic properties, while MWCNTs are more suitable for reinforcing composite materials due to their robustness.

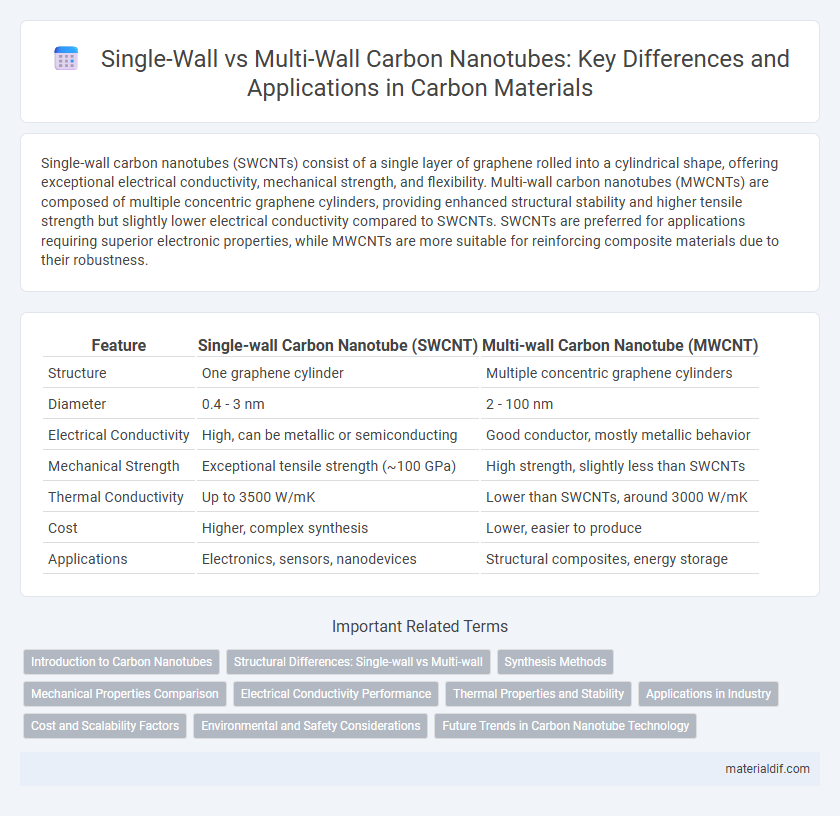

Table of Comparison

| Feature | Single-wall Carbon Nanotube (SWCNT) | Multi-wall Carbon Nanotube (MWCNT) |

|---|---|---|

| Structure | One graphene cylinder | Multiple concentric graphene cylinders |

| Diameter | 0.4 - 3 nm | 2 - 100 nm |

| Electrical Conductivity | High, can be metallic or semiconducting | Good conductor, mostly metallic behavior |

| Mechanical Strength | Exceptional tensile strength (~100 GPa) | High strength, slightly less than SWCNTs |

| Thermal Conductivity | Up to 3500 W/mK | Lower than SWCNTs, around 3000 W/mK |

| Cost | Higher, complex synthesis | Lower, easier to produce |

| Applications | Electronics, sensors, nanodevices | Structural composites, energy storage |

Introduction to Carbon Nanotubes

Single-wall carbon nanotubes (SWCNTs) consist of a single graphene sheet rolled into a cylindrical shape with typical diameters of about 1 nm, offering exceptional electrical conductivity and mechanical strength. Multi-wall carbon nanotubes (MWCNTs) comprise multiple concentric graphene cylinders, with diameters ranging from 5 to 50 nm, providing enhanced durability and thermal stability. Both types of carbon nanotubes exhibit unique properties critical for applications in nanotechnology, electronics, and materials science.

Structural Differences: Single-wall vs Multi-wall

Single-wall carbon nanotubes (SWCNTs) consist of a single cylindrical graphene sheet with a typical diameter of about 0.7 to 2 nanometers, providing high electrical conductivity and flexibility. Multi-wall carbon nanotubes (MWCNTs) feature multiple concentric graphene cylinders with diameters ranging from 2 to 100 nanometers, resulting in enhanced mechanical strength and better durability. The structural difference between SWCNTs and MWCNTs directly influences their thermal, electrical, and mechanical properties, making them suitable for distinct applications in nanotechnology and materials science.

Synthesis Methods

Single-wall carbon nanotubes (SWCNTs) are typically synthesized using chemical vapor deposition (CVD), arc discharge, and laser ablation techniques, with CVD offering high purity and controlled tube diameter. Multi-wall carbon nanotubes (MWCNTs) are commonly produced via CVD and arc discharge methods, which allow for scalable production but may result in a broader diameter distribution and increased defects. Synthesis parameters such as temperature, catalyst type, and gas composition critically influence the structural quality and yield of both SWCNTs and MWCNTs.

Mechanical Properties Comparison

Single-wall carbon nanotubes (SWCNTs) exhibit higher tensile strength, reaching up to 63 GPa, compared to multi-wall carbon nanotubes (MWCNTs), which typically achieve around 30-50 GPa. SWCNTs demonstrate superior Young's modulus values near 1 TPa, whereas MWCNTs show slightly lower moduli due to interlayer interactions and defects. However, MWCNTs provide enhanced toughness and improved resistance to shear forces, benefiting applications requiring durability under complex mechanical stresses.

Electrical Conductivity Performance

Single-wall carbon nanotubes (SWCNTs) exhibit superior electrical conductivity due to their seamless cylindrical graphene structure, which allows ballistic electron transport with minimal scattering. Multi-wall carbon nanotubes (MWCNTs) have multiple concentric graphene layers, causing interlayer interactions that increase resistance and reduce overall conductivity. SWCNTs are preferred in high-performance electronic devices where maximum electrical conductivity and nanoscale dimensions are critical.

Thermal Properties and Stability

Single-wall carbon nanotubes (SWCNTs) demonstrate superior thermal conductivity, reaching values up to 3500 W/m*K, due to their uniform atomic structure and fewer defects. Multi-wall carbon nanotubes (MWCNTs) exhibit enhanced thermal stability, maintaining structural integrity at temperatures above 1000degC, attributed to their multiple concentric graphene layers. The thermal performance of SWCNTs is optimal for heat dissipation applications, whereas MWCNTs offer durability in high-temperature environments.

Applications in Industry

Single-wall carbon nanotubes (SWCNTs) exhibit superior electrical conductivity and mechanical strength, making them ideal for use in nanoelectronics, sensors, and high-performance composites in aerospace and automotive industries. Multi-wall carbon nanotubes (MWCNTs) offer enhanced thermal stability and cost-effectiveness, which are advantageous for energy storage devices, conductive coatings, and reinforced polymer materials. The selection between SWCNTs and MWCNTs depends on application-specific requirements, balancing performance, durability, and economic factors.

Cost and Scalability Factors

Single-wall carbon nanotubes (SWCNTs) generally have higher production costs due to their complex synthesis methods and strict quality control requirements, limiting large-scale manufacturing. Multi-wall carbon nanotubes (MWCNTs) offer more cost-effective and scalable production processes, making them more suitable for bulk applications. The trade-off between SWCNTs' superior electrical and mechanical properties and MWCNTs' economic scalability often guides material selection in industrial applications.

Environmental and Safety Considerations

Single-wall carbon nanotubes (SWCNTs) and multi-wall carbon nanotubes (MWCNTs) exhibit distinct environmental and safety profiles due to their structural differences; SWCNTs, with smaller diameters and higher surface area, tend to pose greater respiratory risks during inhalation exposure. MWCNTs, characterized by multiple concentric graphene layers, exhibit increased durability and persistence in the environment, raising concerns about long-term ecological accumulation and toxicity. Both nanomaterials require rigorous handling protocols and environmental impact assessments to mitigate potential health hazards and ensure safe industrial applications.

Future Trends in Carbon Nanotube Technology

Single-wall carbon nanotubes (SWCNTs) offer superior electrical conductivity and mechanical strength, making them ideal for next-generation nanoelectronic devices and flexible transparent conductors. Multi-wall carbon nanotubes (MWCNTs) provide enhanced thermal stability and robustness, enabling their application in high-performance composites and energy storage systems. Future trends in carbon nanotube technology emphasize hybrid CNT structures and scalable synthesis methods to optimize performance for advanced electronics, energy, and biomedical uses.

Single-wall carbon nanotube vs Multi-wall carbon nanotube Infographic

materialdif.com

materialdif.com