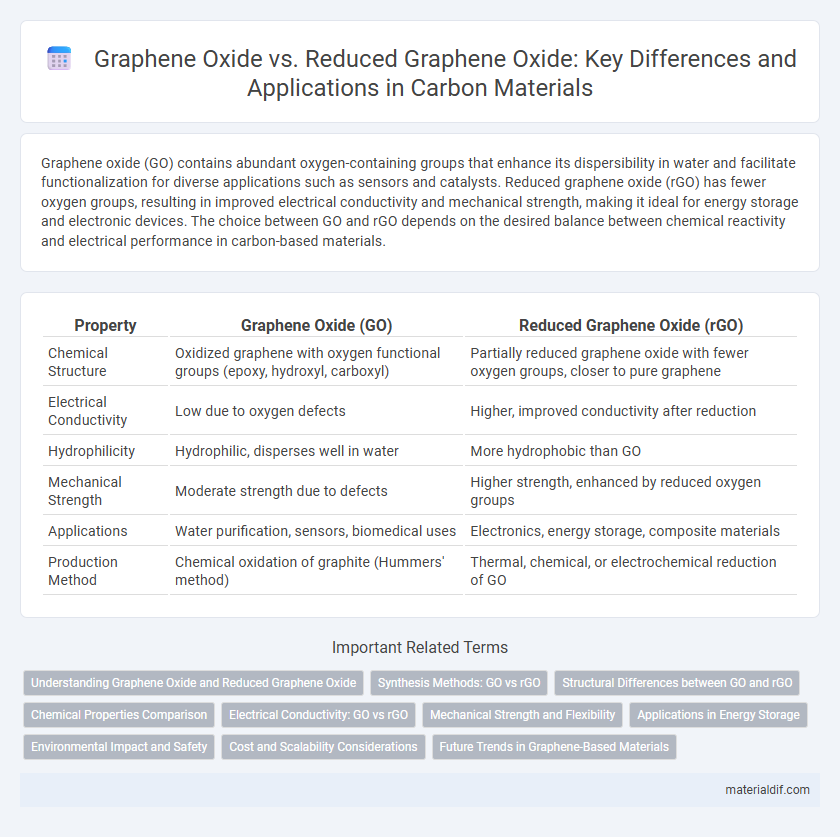

Graphene oxide (GO) contains abundant oxygen-containing groups that enhance its dispersibility in water and facilitate functionalization for diverse applications such as sensors and catalysts. Reduced graphene oxide (rGO) has fewer oxygen groups, resulting in improved electrical conductivity and mechanical strength, making it ideal for energy storage and electronic devices. The choice between GO and rGO depends on the desired balance between chemical reactivity and electrical performance in carbon-based materials.

Table of Comparison

| Property | Graphene Oxide (GO) | Reduced Graphene Oxide (rGO) |

|---|---|---|

| Chemical Structure | Oxidized graphene with oxygen functional groups (epoxy, hydroxyl, carboxyl) | Partially reduced graphene oxide with fewer oxygen groups, closer to pure graphene |

| Electrical Conductivity | Low due to oxygen defects | Higher, improved conductivity after reduction |

| Hydrophilicity | Hydrophilic, disperses well in water | More hydrophobic than GO |

| Mechanical Strength | Moderate strength due to defects | Higher strength, enhanced by reduced oxygen groups |

| Applications | Water purification, sensors, biomedical uses | Electronics, energy storage, composite materials |

| Production Method | Chemical oxidation of graphite (Hummers' method) | Thermal, chemical, or electrochemical reduction of GO |

Understanding Graphene Oxide and Reduced Graphene Oxide

Graphene oxide (GO) consists of graphene sheets functionalized with oxygen-containing groups, enhancing its hydrophilicity and enabling easy dispersion in water, which is crucial for various industrial and biomedical applications. Reduced graphene oxide (rGO) results from the chemical, thermal, or electrochemical reduction of GO, restoring electrical conductivity and improving mechanical properties by partially removing the oxygen groups. Understanding the structural differences between GO and rGO is essential for optimizing their use in energy storage, sensors, and composite materials.

Synthesis Methods: GO vs rGO

Graphene oxide (GO) is typically synthesized through the oxidation of graphite using methods such as Hummers' or modified Hummers' method, which introduces oxygen-containing functional groups. Reduced graphene oxide (rGO) is produced by chemically, thermally, or electrochemically reducing GO, removing oxygen groups to restore electrical conductivity. The synthesis of rGO involves reducing agents like hydrazine, sodium borohydride, or thermal annealing to achieve a more conductive material compared to GO.

Structural Differences between GO and rGO

Graphene oxide (GO) contains abundant oxygen functional groups such as epoxy, hydroxyl, and carboxyl groups distributed on its basal plane and edges, resulting in a disrupted sp2 carbon network and increased interlayer spacing. Reduced graphene oxide (rGO) undergoes chemical, thermal, or electrochemical reduction processes that partially remove these oxygen functionalities, restoring the conjugated graphene lattice and improving electrical conductivity. The structural transition from GO to rGO involves decreased oxygen content, reduced defects, and a more ordered carbon framework resembling pristine graphene.

Chemical Properties Comparison

Graphene oxide (GO) features abundant oxygen-containing functional groups such as epoxides, hydroxyls, and carboxyls, which impart hydrophilicity and high chemical reactivity, enabling facile dispersion in aqueous solutions. Reduced graphene oxide (rGO) undergoes partial removal of these oxygen functionalities through chemical, thermal, or electrochemical reduction, restoring electrical conductivity and increasing hydrophobicity but maintaining some defects and residual oxygen. The varying degrees of oxidation and reduction influence their chemical stability, surface charge, and interaction with other molecules, impacting applications in sensors, catalysis, and energy storage.

Electrical Conductivity: GO vs rGO

Graphene oxide (GO) exhibits significantly lower electrical conductivity due to the presence of abundant oxygen-containing functional groups that disrupt its sp2 carbon network. Reduced graphene oxide (rGO) partially restores the conjugated graphene structure by removing these functional groups, resulting in enhanced electrical conductivity typically ranging from 10 to 10^3 S/m compared to GO's insulating behavior. The degree of reduction and residual oxygen content in rGO critically influence its conductivity, making it a more suitable candidate for applications requiring efficient charge transport.

Mechanical Strength and Flexibility

Graphene oxide (GO) exhibits moderate mechanical strength due to abundant oxygen functional groups disrupting its lattice, while reduced graphene oxide (rGO) demonstrates enhanced mechanical strength resulting from partial restoration of the sp2 carbon network during reduction. Flexibility in GO is limited by its hydrophilic nature and structural defects, whereas rGO offers improved flexibility with increased conductivity and reduced defects, making it more suitable for flexible electronics and composite materials. The balance between mechanical strength and flexibility in rGO makes it a superior choice for applications requiring durable yet adaptable carbon-based materials.

Applications in Energy Storage

Graphene oxide (GO) exhibits excellent dispersibility and functional groups that enhance electrode compatibility in supercapacitors and lithium-ion batteries, improving charge storage capacity. Reduced graphene oxide (rGO) offers higher electrical conductivity and stability, making it ideal for high-performance energy storage devices requiring rapid charge-discharge cycles and long cycle life. The combination of GO's surface chemistry and rGO's conductivity enables advanced hybrid electrodes for next-generation energy storage applications.

Environmental Impact and Safety

Graphene oxide (GO) exhibits higher hydrophilicity and dispersibility in water, which facilitates its biodegradation and reduces environmental persistence compared to reduced graphene oxide (rGO). The reduction process of GO to rGO often involves toxic chemicals and generates hazardous byproducts, raising concerns about environmental contamination and worker safety. Studies indicate GO has lower cytotoxicity and environmental toxicity, making it a safer option for applications where ecological and human health impact are critical.

Cost and Scalability Considerations

Graphene oxide (GO) is generally more cost-effective to produce at scale due to simpler and safer oxidation methods using abundant graphite, making it suitable for large-volume applications. Reduced graphene oxide (rGO) requires additional reduction processes, increasing production complexity and costs, which limits its scalability despite enhanced conductivity and performance. Industries prioritize GO for cost-sensitive projects while reserving rGO for advanced applications demanding higher electrical properties, balancing economic and functional needs.

Future Trends in Graphene-Based Materials

Graphene oxide (GO) and reduced graphene oxide (rGO) continue to shape future trends in graphene-based materials due to their distinct chemical properties and functionalities. GO's abundant oxygen-containing groups enable applications in sensing, water purification, and biomedicine, while rGO's restored conductivity and structural integrity favor electronics, energy storage, and composite materials. Emerging research trends emphasize hybrid materials combining GO and rGO for tunable properties, scalable production methods, and environmentally friendly reduction processes to enhance performance in flexible electronics, supercapacitors, and catalysis.

Graphene oxide vs Reduced graphene oxide Infographic

materialdif.com

materialdif.com