Carbon composite materials consist of carbon fibers embedded in a resin matrix, offering superior strength-to-weight ratios and enhanced durability for high-performance applications. Carbon laminate, created by layering thin sheets of carbon fiber fabric with resin and curing under heat and pressure, provides increased stiffness and structural integrity while maintaining lightweight properties. Both materials excel in aerospace, automotive, and sports equipment, but carbon composites typically deliver more optimized mechanical performance across complex geometries.

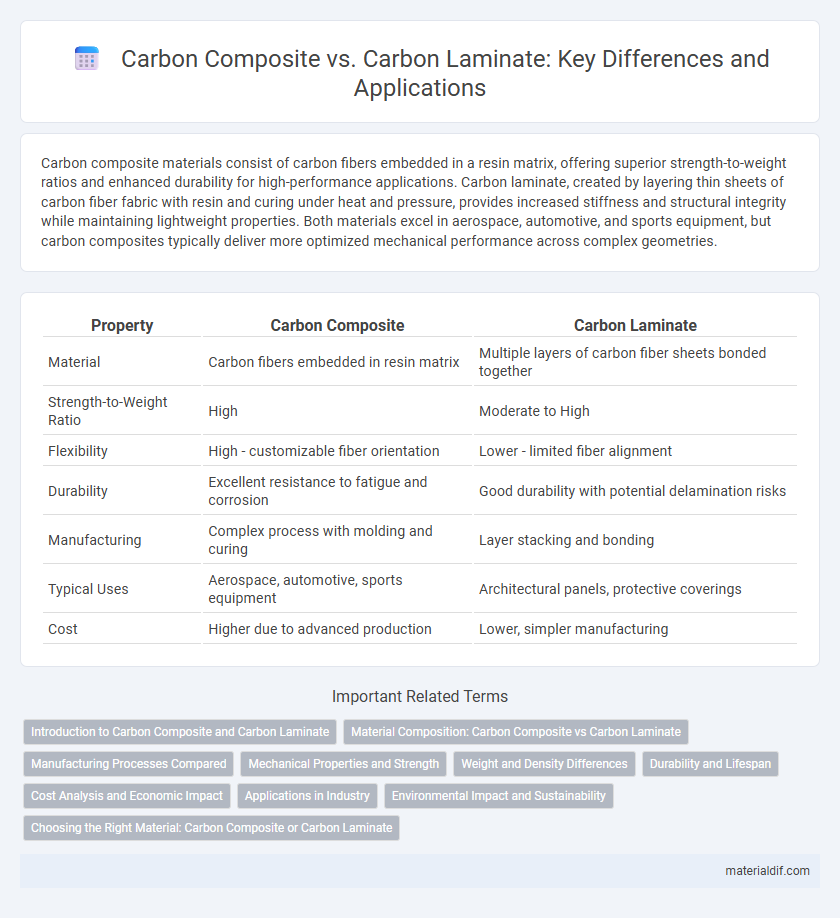

Table of Comparison

| Property | Carbon Composite | Carbon Laminate |

|---|---|---|

| Material | Carbon fibers embedded in resin matrix | Multiple layers of carbon fiber sheets bonded together |

| Strength-to-Weight Ratio | High | Moderate to High |

| Flexibility | High - customizable fiber orientation | Lower - limited fiber alignment |

| Durability | Excellent resistance to fatigue and corrosion | Good durability with potential delamination risks |

| Manufacturing | Complex process with molding and curing | Layer stacking and bonding |

| Typical Uses | Aerospace, automotive, sports equipment | Architectural panels, protective coverings |

| Cost | Higher due to advanced production | Lower, simpler manufacturing |

Introduction to Carbon Composite and Carbon Laminate

Carbon composite materials consist of carbon fibers embedded in a polymer matrix, providing a high strength-to-weight ratio and excellent stiffness. Carbon laminate involves layering sheets of carbon fiber fabric, bonded with resin to form a solid panel with enhanced durability and resistance to impact. Both materials are widely used in aerospace, automotive, and sporting goods industries for their superior mechanical properties and lightweight characteristics.

Material Composition: Carbon Composite vs Carbon Laminate

Carbon composite consists of carbon fibers embedded in a polymer matrix, providing a lightweight yet strong material with high tensile strength and excellent fatigue resistance. Carbon laminate is formed by stacking multiple layers of carbon fiber sheets bonded together with resin, resulting in a rigid and durable material optimized for structural applications. The primary difference lies in the manufacturing process and layer orientation, which influence mechanical properties and performance in aerospace, automotive, and sporting goods industries.

Manufacturing Processes Compared

Carbon composites are created by embedding carbon fibers within a polymer matrix, usually through processes like layup, resin transfer molding, or autoclave curing, offering high strength-to-weight ratios and design flexibility. Carbon laminates consist of multiple thin carbon fiber sheets bonded with adhesives or resins, manufactured through techniques such as vacuum bagging or compression molding, emphasizing uniformity and surface finish. Manufacturing carbon composites often involves more complex equipment and curing steps than carbon laminates, which are generally simpler and faster to produce but may have different mechanical properties.

Mechanical Properties and Strength

Carbon composites exhibit superior mechanical properties and strength due to their fiber-reinforced matrix structure, offering high tensile strength and excellent stiffness. Carbon laminates, while also strong, consist of layered sheets with less fiber continuity, resulting in lower impact resistance and tensile strength compared to composites. The anisotropic nature of carbon composites provides tailored strength and durability optimized for high-performance applications, unlike the more uniform but less robust lamination.

Weight and Density Differences

Carbon composites typically exhibit lower weight and density compared to carbon laminates due to their fiber-reinforced polymer matrix structure, which optimizes strength-to-weight ratio. Carbon laminates consist of multiple layers of carbon fiber sheets bonded together, resulting in slightly higher density and increased weight but enhanced stiffness and structural integrity. Weight differences between the two materials influence application choices, with composites favored in aerospace and automotive industries for lightweight performance and laminates chosen for durability and load-bearing requirements.

Durability and Lifespan

Carbon composite materials exhibit superior durability and a longer lifespan compared to carbon laminates due to their multi-directional fiber reinforcement and strong polymer matrix bonding. Carbon composites resist fatigue, corrosion, and environmental degradation more effectively, making them ideal for high-stress applications like aerospace and automotive components. In contrast, carbon laminates, composed of layered sheets, tend to delaminate under prolonged stress and offer lower resistance to impact and wear, resulting in a reduced operational lifespan.

Cost Analysis and Economic Impact

Carbon composites typically incur higher upfront costs due to complex manufacturing and advanced material requirements, while carbon laminates offer a more cost-effective solution with simpler production processes. Economically, carbon composites deliver superior strength-to-weight ratios that justify investments in aerospace and automotive industries through long-term fuel savings and performance enhancements. The choice between these materials hinges on balancing initial expenditures with lifecycle benefits and application-specific demands.

Applications in Industry

Carbon composites, composed of carbon fibers embedded in a polymer matrix, offer exceptional strength-to-weight ratio, making them ideal for aerospace, automotive, and sporting goods industries where lightweight durability is crucial. Carbon laminates, typically thin layers of carbon fiber sheets bonded together, provide high stiffness and surface strength, frequently used in electronics, construction, and protective gear manufacturing for enhanced rigidity and impact resistance. In industry applications, carbon composites dominate structural components requiring complex shapes and load-bearing capacity, while carbon laminates excel in applications demanding flat, rigid surfaces with superior wear resistance.

Environmental Impact and Sustainability

Carbon composite materials showcase superior strength-to-weight ratios and longer lifespans compared to carbon laminates, resulting in lower overall environmental impact through reduced resource consumption and less frequent replacement. The production process of carbon composites, while energy-intensive, benefits from advances in recycling technologies that enhance material reuse and decrease landfill waste. In contrast, carbon laminates tend to involve simpler manufacturing but generate more waste and have limited recyclability, posing greater challenges for sustainability efforts.

Choosing the Right Material: Carbon Composite or Carbon Laminate

Carbon composites offer superior strength-to-weight ratios due to their woven carbon fiber matrix bonded with resin, making them ideal for high-performance applications requiring lightweight durability. Carbon laminates consist of multiple layers of carbon fiber sheets bonded together, providing enhanced stiffness and surface finish suitable for structural panels and aesthetic components. Selecting between carbon composite and carbon laminate depends on factors such as mechanical strength, weight considerations, and the desired balance between flexibility and rigidity in the final product.

Carbon composite vs Carbon laminate Infographic

materialdif.com

materialdif.com