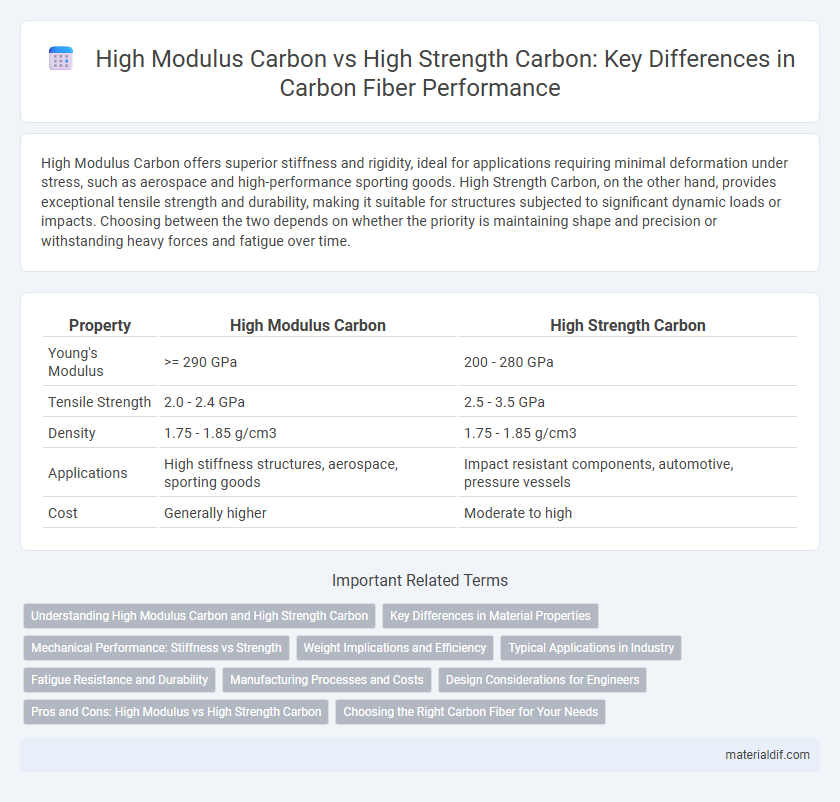

High Modulus Carbon offers superior stiffness and rigidity, ideal for applications requiring minimal deformation under stress, such as aerospace and high-performance sporting goods. High Strength Carbon, on the other hand, provides exceptional tensile strength and durability, making it suitable for structures subjected to significant dynamic loads or impacts. Choosing between the two depends on whether the priority is maintaining shape and precision or withstanding heavy forces and fatigue over time.

Table of Comparison

| Property | High Modulus Carbon | High Strength Carbon |

|---|---|---|

| Young's Modulus | >= 290 GPa | 200 - 280 GPa |

| Tensile Strength | 2.0 - 2.4 GPa | 2.5 - 3.5 GPa |

| Density | 1.75 - 1.85 g/cm3 | 1.75 - 1.85 g/cm3 |

| Applications | High stiffness structures, aerospace, sporting goods | Impact resistant components, automotive, pressure vessels |

| Cost | Generally higher | Moderate to high |

Understanding High Modulus Carbon and High Strength Carbon

High Modulus Carbon fibers exhibit superior stiffness and rigidity, making them ideal for aerospace and high-performance automotive applications where minimal deformation is critical. High Strength Carbon fibers prioritize tensile strength and impact resistance, offering enhanced durability for sports equipment and structural components subject to dynamic loads. The distinction between these two types lies in balancing elasticity and tensile strength to meet specific engineering requirements.

Key Differences in Material Properties

High modulus carbon fibers exhibit greater stiffness, characterized by a higher Young's modulus typically ranging from 230 to 600 GPa, making them ideal for applications requiring minimal deformation under stress. In contrast, high strength carbon fibers prioritize tensile strength, with values often exceeding 4 GPa, enhancing their resistance to fracture and impact forces. The trade-off between modulus and strength affects composite performance, where high modulus fibers enhance rigidity and dimensional stability, while high strength fibers improve toughness and load-bearing capacity.

Mechanical Performance: Stiffness vs Strength

High Modulus Carbon fibers excel in stiffness due to their high tensile modulus, making them ideal for applications requiring minimal deformation under load. In contrast, High Strength Carbon fibers offer superior tensile strength, providing better resistance to fracture and damage in structures subjected to high stress. Selecting between these types depends on whether the mechanical performance prioritizes rigidity or load-bearing capacity in the composite material.

Weight Implications and Efficiency

High Modulus Carbon fibers offer superior stiffness with lower density, resulting in lighter components ideal for applications where weight reduction directly enhances performance efficiency. High Strength Carbon fibers provide greater tensile strength but typically at a slightly higher weight, making them suitable for structures needing maximum load-bearing capacity without excessive mass. Balancing weight implications and efficiency, High Modulus Carbon is preferred in aerospace and automotive industries aiming to optimize fuel economy and speed through lightweight materials.

Typical Applications in Industry

High Modulus Carbon fibers are primarily used in aerospace and high-performance sporting goods where stiffness and lightweight properties are critical, such as in aircraft wings, satellite components, and racing bicycles. High Strength Carbon fibers find widespread application in automotive manufacturing, civil engineering, and pressure vessels, offering excellent fatigue resistance and impact toughness for structural reinforcements and safety equipment. Both fiber types enhance material performance but are selected based on the specific demands for rigidity or durability in industry.

Fatigue Resistance and Durability

High modulus carbon offers superior stiffness and reduced elongation under stress, making it ideal for applications requiring precise structural integrity but typically has lower fatigue resistance compared to high strength carbon. High strength carbon excels in fatigue resistance and durability due to its enhanced ability to withstand cyclic loading and impact without fracturing. Selecting between high modulus and high strength carbon depends on balancing stiffness requirements with long-term durability and fatigue performance in demanding environments.

Manufacturing Processes and Costs

High Modulus Carbon fibers undergo an energy-intensive manufacturing process involving advanced stabilization and carbonization techniques to achieve superior stiffness, resulting in higher production costs compared to High Strength Carbon fibers. High Strength Carbon fibers are produced using less complex processes that emphasize tensile strength through optimized precursor materials like PAN and streamlined carbonization, offering a more cost-effective solution. Differences in precursor treatment, temperature control, and fiber spinning methods significantly impact the manufacturing efficiency and economic feasibility of both fiber types.

Design Considerations for Engineers

High Modulus Carbon offers superior stiffness with a modulus typically above 50 Msi, ideal for applications requiring minimal deflection and precise structural stability. High Strength Carbon, with tensile strength exceeding 500 ksi, is preferred in designs prioritizing impact resistance and durability under dynamic loads. Engineers must evaluate the specific load conditions and required mechanical performance to select the optimal carbon fiber variant, balancing stiffness against strength for maximum design efficiency.

Pros and Cons: High Modulus vs High Strength Carbon

High Modulus carbon fibers offer superior stiffness and dimensional stability, making them ideal for aerospace and high-performance applications where rigidity is critical, but they tend to be more brittle and expensive. High Strength carbon fibers provide enhanced tensile strength and impact resistance, suitable for automotive and sporting goods requiring durability and toughness, though they have lower stiffness compared to High Modulus variants. Selecting between High Modulus and High Strength carbon depends on balancing the need for stiffness versus strength, cost constraints, and specific performance requirements.

Choosing the Right Carbon Fiber for Your Needs

High Modulus Carbon fibers offer exceptional stiffness and dimensional stability, making them ideal for aerospace and precision engineering applications where rigidity is paramount. High Strength Carbon fibers provide superior tensile strength and impact resistance, better suited for automotive, sporting goods, and structural components requiring durability under stress. Selecting the right carbon fiber depends on the specific performance requirements, balancing stiffness versus strength based on environmental and load conditions.

High Modulus Carbon vs High Strength Carbon Infographic

materialdif.com

materialdif.com