Carbon filled polymers exhibit enhanced mechanical strength, thermal conductivity, and electrical properties compared to pure polymers due to the integration of carbon particles into the polymer matrix. The carbon fillers improve stiffness and durability while maintaining weight advantages, making these composites ideal for automotive and aerospace applications. Pure polymers, in contrast, offer superior flexibility and chemical resistance but lack the reinforced structural benefits provided by carbon filling.

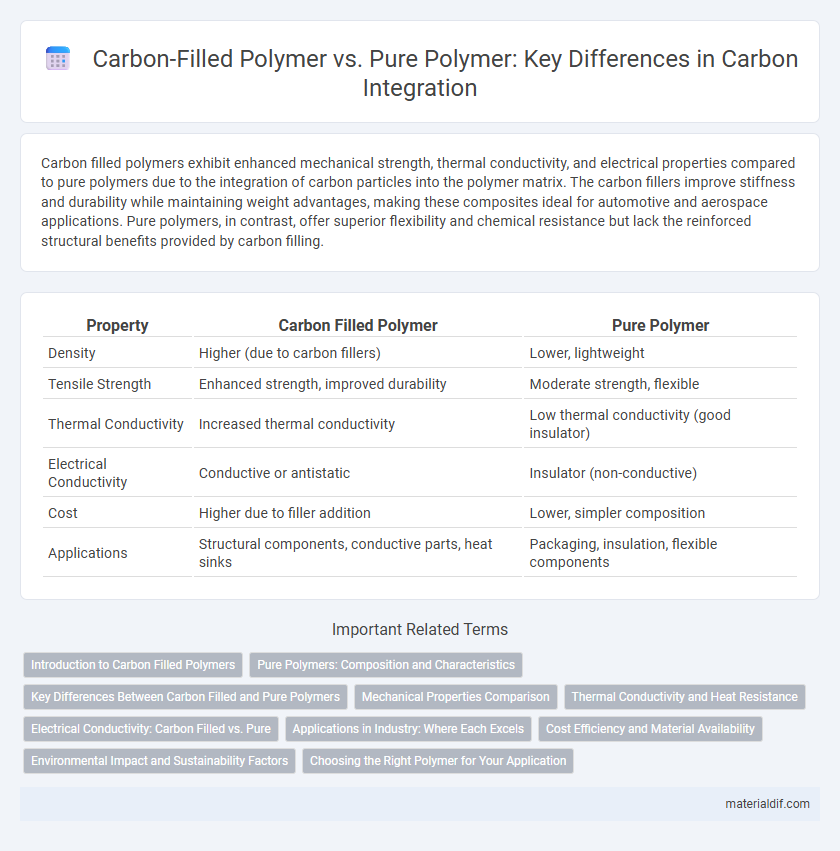

Table of Comparison

| Property | Carbon Filled Polymer | Pure Polymer |

|---|---|---|

| Density | Higher (due to carbon fillers) | Lower, lightweight |

| Tensile Strength | Enhanced strength, improved durability | Moderate strength, flexible |

| Thermal Conductivity | Increased thermal conductivity | Low thermal conductivity (good insulator) |

| Electrical Conductivity | Conductive or antistatic | Insulator (non-conductive) |

| Cost | Higher due to filler addition | Lower, simpler composition |

| Applications | Structural components, conductive parts, heat sinks | Packaging, insulation, flexible components |

Introduction to Carbon Filled Polymers

Carbon filled polymers exhibit enhanced mechanical strength, thermal stability, and electrical conductivity compared to pure polymers due to the incorporation of carbon-based fillers like carbon black or carbon fibers. These composite materials leverage the high surface area and exceptional properties of carbon to improve durability and performance in automotive, aerospace, and electronics applications. The optimized interaction between the polymer matrix and carbon fillers results in superior load transfer and improved resistance to wear, making carbon filled polymers a preferred choice for advanced engineering solutions.

Pure Polymers: Composition and Characteristics

Pure polymers consist of long chains of repeating monomer units with uniform molecular structure, resulting in consistent physical and chemical properties. Unlike carbon-filled polymers, pure polymers typically exhibit lower electrical conductivity but higher optical clarity and flexibility. Their inherent characteristics include high purity, predictable thermal stability, and excellent processability, making them ideal for applications requiring consistent performance without reinforcement additives.

Key Differences Between Carbon Filled and Pure Polymers

Carbon filled polymers exhibit enhanced mechanical strength, thermal conductivity, and electrical conductivity compared to pure polymers due to the dispersion of carbon particles within the polymer matrix. Pure polymers generally offer superior flexibility, chemical resistance, and ease of processing but lack the reinforced structural and conductive properties provided by carbon fillers. The choice between carbon filled and pure polymers depends on application requirements such as durability, conductivity, and weight optimization.

Mechanical Properties Comparison

Carbon-filled polymers exhibit significantly enhanced mechanical properties compared to pure polymers, including increased tensile strength, stiffness, and impact resistance due to the reinforcing effect of carbon particles. The incorporation of carbon fillers improves load transfer capabilities and reduces deformation under stress, making these composites ideal for high-performance applications. Unlike pure polymers, carbon-filled variants also demonstrate superior fatigue resistance and dimensional stability, extending their service life in demanding mechanical environments.

Thermal Conductivity and Heat Resistance

Carbon filled polymers exhibit significantly enhanced thermal conductivity compared to pure polymers, enabling improved heat dissipation in electronic and automotive applications. The incorporation of carbon fillers, such as carbon nanotubes or graphene, increases the composite's ability to withstand higher temperatures without degradation, boosting heat resistance. Pure polymers typically have low thermal conductivity and limited heat resistance, restricting their use in high-temperature or thermally demanding environments.

Electrical Conductivity: Carbon Filled vs. Pure

Carbon filled polymers exhibit significantly higher electrical conductivity compared to pure polymers due to the conductive pathways formed by carbon particles within the polymer matrix. Pure polymers generally act as electrical insulators with very low conductivity values, often below 10^-12 S/cm. The incorporation of carbon fillers, such as carbon black or carbon nanotubes, enhances conductivity by several orders of magnitude, enabling applications in electromagnetic interference shielding and antistatic materials.

Applications in Industry: Where Each Excels

Carbon filled polymers show superior mechanical strength, thermal conductivity, and electrical conductivity compared to pure polymers, making them ideal for automotive parts, aerospace components, and electronic housings where durability and performance under stress are critical. Pure polymers excel in applications requiring chemical resistance, flexibility, and ease of processing, such as packaging, medical devices, and textile fibers. The integration of carbon fillers enhances the functional properties of polymers without compromising weight, expanding their use in demanding industrial environments.

Cost Efficiency and Material Availability

Carbon-filled polymers offer enhanced mechanical properties at a higher cost compared to pure polymers, impacting cost efficiency depending on application requirements. Pure polymers generally provide lower material expenses and greater availability, making them suitable for mass production and budget-sensitive projects. The trade-off between improved durability from carbon fillers and the affordability of pure polymers shapes material selection in industrial manufacturing.

Environmental Impact and Sustainability Factors

Carbon-filled polymers exhibit enhanced mechanical properties and durability compared to pure polymers, leading to longer product lifespans and reduced material consumption. The incorporation of carbon fillers can improve recyclability and reduce the carbon footprint by enabling lightweight designs and energy savings during use. However, sourcing and processing carbon fillers may involve higher energy inputs and environmental considerations compared to producing pure polymers.

Choosing the Right Polymer for Your Application

Carbon-filled polymers offer enhanced mechanical strength, thermal stability, and electrical conductivity compared to pure polymers, making them ideal for high-performance applications. Pure polymers provide excellent flexibility, chemical resistance, and lower weight, which suits applications requiring easy processing and cost-effectiveness. Selecting the right polymer depends on balancing specific application requirements, such as durability and conductivity, against factors like manufacturing complexity and budget constraints.

Carbon filled polymer vs Pure polymer Infographic

materialdif.com

materialdif.com