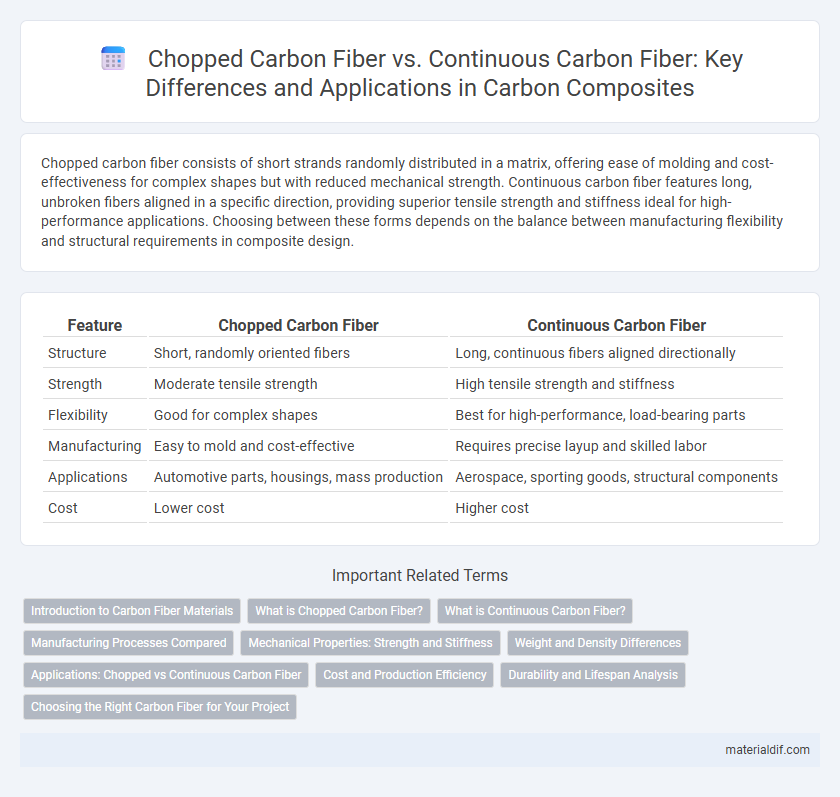

Chopped carbon fiber consists of short strands randomly distributed in a matrix, offering ease of molding and cost-effectiveness for complex shapes but with reduced mechanical strength. Continuous carbon fiber features long, unbroken fibers aligned in a specific direction, providing superior tensile strength and stiffness ideal for high-performance applications. Choosing between these forms depends on the balance between manufacturing flexibility and structural requirements in composite design.

Table of Comparison

| Feature | Chopped Carbon Fiber | Continuous Carbon Fiber |

|---|---|---|

| Structure | Short, randomly oriented fibers | Long, continuous fibers aligned directionally |

| Strength | Moderate tensile strength | High tensile strength and stiffness |

| Flexibility | Good for complex shapes | Best for high-performance, load-bearing parts |

| Manufacturing | Easy to mold and cost-effective | Requires precise layup and skilled labor |

| Applications | Automotive parts, housings, mass production | Aerospace, sporting goods, structural components |

| Cost | Lower cost | Higher cost |

Introduction to Carbon Fiber Materials

Chopped carbon fiber consists of short strands typically measuring a few millimeters, offering ease of molding and cost efficiency for complex shapes and mass production. Continuous carbon fiber features long, unbroken fibers, providing superior strength, stiffness, and load-bearing capacity ideal for aerospace, automotive, and sporting goods applications. The distinct structural properties influence material selection based on performance requirements and manufacturing processes in carbon fiber composites.

What is Chopped Carbon Fiber?

Chopped carbon fiber consists of short strands of carbon fiber typically ranging from a few millimeters to several centimeters in length, used as reinforcement in composite materials. This form enhances material properties like tensile strength and impact resistance while allowing for more versatile molding processes compared to continuous carbon fiber. Chopped carbon fiber is commonly employed in injection molding and additive manufacturing due to its ability to improve stiffness and reduce weight without the complexities of aligning continuous fibers.

What is Continuous Carbon Fiber?

Continuous carbon fiber consists of long, unbroken strands of carbon fibers woven or aligned in a single direction, offering superior tensile strength and stiffness compared to chopped carbon fiber. This material is essential in high-performance applications such as aerospace, automotive, and sporting goods, where maximum strength-to-weight ratios are critical. Continuous carbon fiber composites provide enhanced load transfer capabilities and improved fatigue resistance, making them ideal for structural components.

Manufacturing Processes Compared

Chopped carbon fiber is produced by cutting continuous carbon fibers into short lengths, which are then mixed with resins to create molded composite materials ideal for complex shapes and automated manufacturing processes like injection molding. Continuous carbon fiber manufacturing involves weaving or laying fibers in long, unbroken sheets that are consolidated with resin through processes such as prepreg layup and vacuum bagging, resulting in superior mechanical properties and structural integrity. The manufacturing choice between chopped and continuous carbon fiber significantly impacts the strength, stiffness, and production efficiency of composite components.

Mechanical Properties: Strength and Stiffness

Chopped carbon fiber consists of short strands that provide isotropic reinforcement, resulting in moderate strength and stiffness ideal for complex shapes and impact resistance. Continuous carbon fiber features long, aligned fibers that deliver superior tensile strength and stiffness along the fiber direction, making it optimal for load-bearing structural applications. The mechanical properties of continuous carbon fiber outperform chopped variants in stiffness-to-weight ratio and tensile strength, crucial for aerospace and automotive components.

Weight and Density Differences

Chopped carbon fiber consists of short strands resulting in higher density and slightly increased weight compared to continuous carbon fiber, which features long, aligned fibers offering superior strength-to-weight ratios. Continuous carbon fiber's uniform structure reduces material density, enhancing performance in lightweight applications where minimizing mass is critical. Weight differences between the two impact design choices in aerospace and automotive industries, where continuous fibers optimize strength without sacrificing lightness.

Applications: Chopped vs Continuous Carbon Fiber

Chopped carbon fiber offers enhanced moldability and cost efficiency, making it ideal for complex shapes and automotive interior components where moderate strength is sufficient. Continuous carbon fiber provides superior strength and stiffness, crucial for aerospace structures, sporting goods, and high-performance automotive parts requiring maximum load-bearing capacity. Selecting between chopped and continuous carbon fiber depends on specific application demands for mechanical performance and manufacturing complexity.

Cost and Production Efficiency

Chopped carbon fiber offers lower material costs due to its shorter fiber lengths and simplified production process, making it ideal for high-volume manufacturing with moderate strength requirements. Continuous carbon fiber demands higher investment in raw materials and complex layup techniques, resulting in superior mechanical properties but increased production time and expense. Manufacturers often choose chopped carbon fiber for cost-sensitive applications where efficiency outweighs maximum performance.

Durability and Lifespan Analysis

Chopped carbon fiber offers moderate durability with increased isotropic strength but generally exhibits a shorter lifespan due to fiber discontinuities and stress concentrations. Continuous carbon fiber delivers superior durability and extended lifespan by maintaining fiber alignment, which optimizes load distribution and resists fatigue over time. Material selection depends on application requirements, with continuous carbon fiber favored for high-performance, long-term use cases.

Choosing the Right Carbon Fiber for Your Project

Chopped carbon fiber consists of short, randomly oriented strands ideal for complex shapes and cost-effective reinforcement, while continuous carbon fiber features long, aligned fibers that provide superior strength and stiffness for high-performance applications. Selecting the right carbon fiber depends on project requirements like mechanical properties, weight constraints, and manufacturing processes. For structural components with demanding load-bearing needs, continuous carbon fiber offers optimal durability, whereas chopped carbon fiber suits prototype models or intricate geometries where molding flexibility is crucial.

Chopped Carbon Fiber vs Continuous Carbon Fiber Infographic

materialdif.com

materialdif.com