Graphitized carbon exhibits an ordered crystalline structure with high thermal conductivity and electrical conductivity, making it ideal for advanced electronic and industrial applications. Non-graphitized carbon has an amorphous, disordered structure, resulting in lower conductivity but increased chemical reactivity and adsorption capacity. The choice between graphitized and non-graphitized carbon depends on the specific requirements for conductivity, strength, and surface activity in various technological applications.

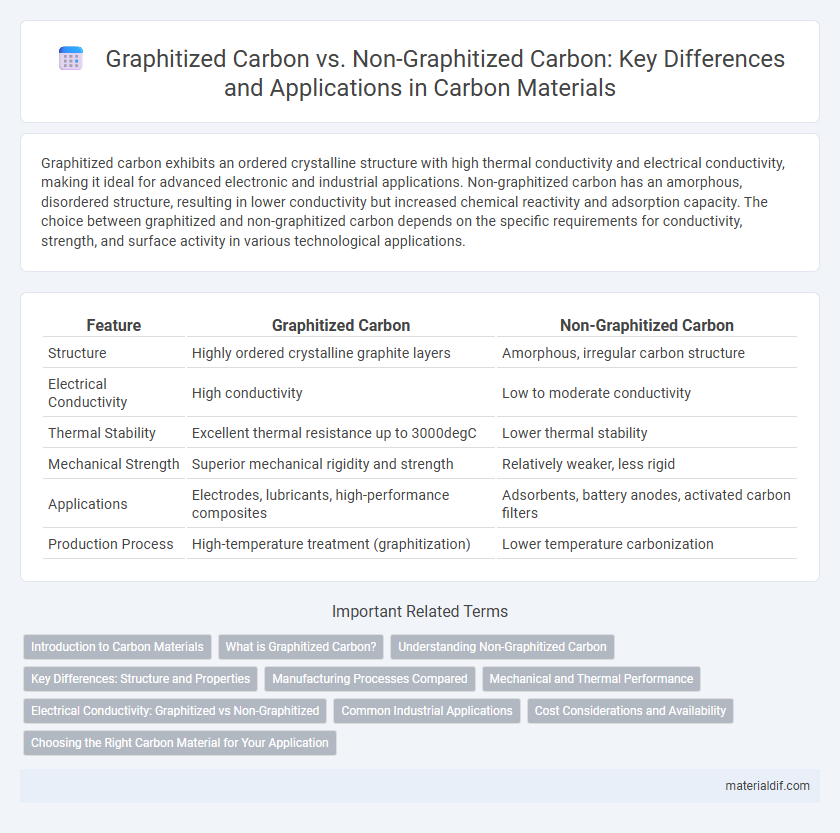

Table of Comparison

| Feature | Graphitized Carbon | Non-Graphitized Carbon |

|---|---|---|

| Structure | Highly ordered crystalline graphite layers | Amorphous, irregular carbon structure |

| Electrical Conductivity | High conductivity | Low to moderate conductivity |

| Thermal Stability | Excellent thermal resistance up to 3000degC | Lower thermal stability |

| Mechanical Strength | Superior mechanical rigidity and strength | Relatively weaker, less rigid |

| Applications | Electrodes, lubricants, high-performance composites | Adsorbents, battery anodes, activated carbon filters |

| Production Process | High-temperature treatment (graphitization) | Lower temperature carbonization |

Introduction to Carbon Materials

Graphitized carbon exhibits a well-ordered crystalline structure with layers of hexagonally arranged carbon atoms, resulting in high electrical conductivity, chemical stability, and superior mechanical strength. Non-graphitized carbon, characterized by its amorphous or disordered atomic arrangement, typically shows lower conductivity and is more reactive due to the presence of numerous defects and functional groups. These structural differences fundamentally influence the performance and application of carbon materials in areas such as energy storage, catalysis, and composite manufacturing.

What is Graphitized Carbon?

Graphitized carbon is a form of carbon material characterized by a highly ordered graphite-like crystalline structure, where carbon atoms are arranged in layers of hexagonal lattices. This structure imparts superior electrical conductivity, thermal stability, and mechanical strength compared to non-graphitized carbon, which lacks this ordered arrangement and is more amorphous. Graphitized carbon is commonly used in applications such as electrodes, batteries, and advanced composites due to its enhanced performance properties.

Understanding Non-Graphitized Carbon

Non-graphitized carbon consists of disordered, amorphous carbon atoms lacking the crystalline structure found in graphitized carbon. This form of carbon exhibits lower electrical conductivity and thermal stability due to its random atomic arrangement, making it more reactive and porous. Non-graphitized carbon is commonly used in applications requiring high surface area and catalytic activity, such as activated carbon filters and electrodes in batteries.

Key Differences: Structure and Properties

Graphitized carbon features a highly ordered crystalline structure characterized by hexagonal layers of carbon atoms arranged in a graphitic lattice, resulting in superior electrical conductivity, thermal stability, and mechanical strength. Non-graphitized carbon, also known as amorphous carbon, lacks long-range order in its atomic structure, displaying random bonding and defects that contribute to higher surface area but lower electrical conductivity and thermal resistance. These structural distinctions directly influence their properties: graphitized carbon excels in applications requiring conductivity and stability, while non-graphitized carbon is favored for adsorption and catalytic support due to its porous nature.

Manufacturing Processes Compared

Graphitized carbon undergoes high-temperature treatment above 2,500degC, which reorganizes carbon atoms into a crystalline, graphite-like structure, resulting in enhanced electrical conductivity and thermal stability. Non-graphitized carbon is produced at lower temperatures, typically below 1,000degC, preserving an amorphous and disordered carbon structure with higher surface area but lower conductivity. The precise thermal conditions and duration during graphitization fundamentally differentiate these carbon types, influencing their physical properties and industrial applications.

Mechanical and Thermal Performance

Graphitized carbon exhibits superior mechanical strength and thermal conductivity due to its ordered crystalline structure, enabling efficient load distribution and heat transfer. Non-graphitized carbon, characterized by its amorphous structure, typically shows lower mechanical durability and reduced thermal performance, leading to higher thermal resistance and increased brittleness. Applications requiring high thermal stability and mechanical resilience favor graphitized carbon over non-graphitized forms.

Electrical Conductivity: Graphitized vs Non-Graphitized

Graphitized carbon exhibits significantly higher electrical conductivity than non-graphitized carbon due to its well-ordered crystalline structure, which facilitates efficient electron mobility. Non-graphitized carbon, characterized by its amorphous and disordered atomic arrangement, presents higher electrical resistance and reduced conductivity. This difference is critical in applications such as batteries, electrodes, and electronic components where conductivity directly impacts performance and efficiency.

Common Industrial Applications

Graphitized carbon is extensively used in high-performance applications such as electrodes for batteries, supercapacitors, and heat exchangers due to its excellent electrical conductivity and thermal stability. Non-graphitized carbon, often referred to as amorphous carbon, finds common industrial applications in activated carbon filters for water purification, gas adsorption, and catalyst support. The structural differences directly influence their functionality, with graphitized carbon favored in energy storage and thermal management, while non-graphitized carbon excels in adsorption and filtration processes.

Cost Considerations and Availability

Graphitized carbon generally commands higher costs due to its complex manufacturing process involving high-temperature treatment and precise structural alignment, making it less readily available compared to non-graphitized carbon. Non-graphitized carbon is more abundant and economical, sourced from simpler production methods such as pyrolyzed organic materials, which enhances its accessibility for large-scale applications. Cost considerations heavily influence material selection in industries like energy storage and filtration, where budget constraints and supply chain reliability are critical.

Choosing the Right Carbon Material for Your Application

Graphitized carbon offers superior electrical conductivity, thermal stability, and chemical resistance, making it ideal for high-performance applications such as electrodes, battery anodes, and advanced composites. Non-graphitized carbon, with its amorphous structure, provides better adsorption properties and is often used in filtration, catalysis support, and activated carbon products. Selecting the right carbon material depends on balancing conductivity, surface area, structural integrity, and cost to meet specific industrial or environmental requirements.

Graphitized carbon vs Non-graphitized carbon Infographic

materialdif.com

materialdif.com