Carbon coating involves applying a thin layer of carbon onto a substrate to enhance surface properties such as conductivity, hardness, and resistance to wear. Carbon infiltration, on the other hand, penetrates carbon into the pores of a material, improving structural integrity and mechanical strength by filling internal voids. Both techniques optimize the performance of carbon-based products, with coating improving surface interaction and infiltration reinforcing the overall material structure.

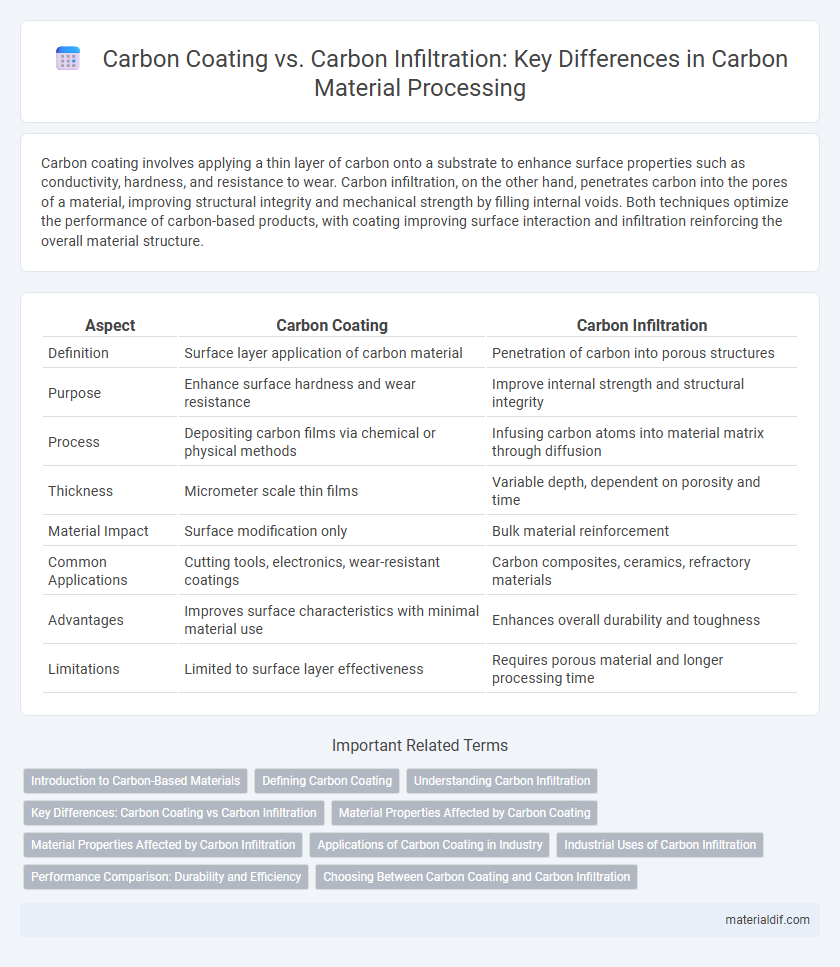

Table of Comparison

| Aspect | Carbon Coating | Carbon Infiltration |

|---|---|---|

| Definition | Surface layer application of carbon material | Penetration of carbon into porous structures |

| Purpose | Enhance surface hardness and wear resistance | Improve internal strength and structural integrity |

| Process | Depositing carbon films via chemical or physical methods | Infusing carbon atoms into material matrix through diffusion |

| Thickness | Micrometer scale thin films | Variable depth, dependent on porosity and time |

| Material Impact | Surface modification only | Bulk material reinforcement |

| Common Applications | Cutting tools, electronics, wear-resistant coatings | Carbon composites, ceramics, refractory materials |

| Advantages | Improves surface characteristics with minimal material use | Enhances overall durability and toughness |

| Limitations | Limited to surface layer effectiveness | Requires porous material and longer processing time |

Introduction to Carbon-Based Materials

Carbon coating forms a thin, uniform layer of carbon atoms on the surface of a substrate, enhancing properties like corrosion resistance, electrical conductivity, and thermal stability. Carbon infiltration involves permeating a carbon-rich precursor into a porous material, followed by pyrolysis to create a carbon matrix within the substrate, improving mechanical strength and durability. These carbon-based materials are essential in applications such as aerospace, electronics, and energy storage due to their versatile structural and functional characteristics.

Defining Carbon Coating

Carbon coating involves applying a thin, uniform layer of carbon onto the surface of a material to enhance properties such as conductivity, corrosion resistance, and wear resistance. This process creates a protective barrier that improves the substrate's performance without significantly altering its bulk characteristics. Carbon infiltration, by contrast, typically refers to embedding carbon deep within a porous structure to reinforce and strengthen the internal matrix.

Understanding Carbon Infiltration

Carbon infiltration involves the process of introducing carbon atoms into the porous structure of a material to enhance its mechanical strength and thermal stability, differing from carbon coating which primarily applies a superficial carbon layer. This method improves the internal bonding and durability of composites, making materials more resistant to wear, oxidation, and high temperatures. Understanding carbon infiltration is essential for applications in aerospace and advanced manufacturing where material performance is critical.

Key Differences: Carbon Coating vs Carbon Infiltration

Carbon coating involves applying a thin carbon layer on surfaces to enhance conductivity, corrosion resistance, and wear properties, while carbon infiltration integrates carbon into porous materials to increase structural integrity and thermal stability. Carbon coating primarily improves surface characteristics without altering the substrate's bulk properties, whereas carbon infiltration modifies the internal matrix of materials for enhanced mechanical performance. The choice between the two depends on whether surface enhancement or bulk material reinforcement is required for specific applications.

Material Properties Affected by Carbon Coating

Carbon coating enhances surface hardness, wear resistance, and corrosion protection by forming a thin, uniform layer of carbon atoms on the substrate, significantly improving durability and reducing friction. This coating modifies electrical conductivity and thermal stability by creating a consistent carbon-rich interface, which is crucial for electronic and high-temperature applications. In contrast, carbon infiltration alters the bulk material by filling pores with carbon, primarily improving structural integrity and density rather than surface properties.

Material Properties Affected by Carbon Infiltration

Carbon infiltration significantly enhances the density and mechanical strength of materials by filling pores with carbon, resulting in improved hardness and wear resistance compared to carbon coating. Unlike thin carbon coatings that primarily affect surface properties, infiltration alters the internal microstructure, boosting thermal conductivity and resistance to chemical degradation. These changes make carbon-infiltrated composites ideal for high-performance applications requiring durability and thermal stability.

Applications of Carbon Coating in Industry

Carbon coating is extensively used in industries such as electronics, aerospace, and automotive for applications requiring enhanced corrosion resistance, electrical conductivity, and thermal stability. It provides a uniform, protective layer that improves the durability and performance of metal components, semiconductor devices, and cutting tools. Unlike carbon infiltration, which penetrates porous materials, carbon coating remains on the surface, making it ideal for surface modification and wear resistance in industrial equipment.

Industrial Uses of Carbon Infiltration

Carbon infiltration is widely used in industrial applications to enhance the structural integrity and thermal stability of refractory materials, such as those in foundries and high-temperature reactors. This process improves material resistance to corrosion and wear by introducing carbon deep into porous substrates, making it ideal for manufacturing components in steelmaking, aerospace, and automotive industries. Compared to carbon coating, which provides a superficial layer, carbon infiltration ensures a more durable and uniform modification essential for heavy-duty industrial environments.

Performance Comparison: Durability and Efficiency

Carbon coating offers enhanced surface hardness and wear resistance, significantly improving durability in high-friction environments, whereas carbon infiltration provides superior structural integrity by embedding carbon deep within the material matrix. Efficiency-wise, carbon coating delivers faster application times and uniform layer control, while carbon infiltration achieves better resistance to thermal and chemical degradation due to its thorough material integration. Performance comparisons indicate carbon infiltration excels in long-term durability for demanding conditions, while carbon coating is preferred for cost-effective, scalable surface protection.

Choosing Between Carbon Coating and Carbon Infiltration

Choosing between carbon coating and carbon infiltration depends on the desired properties and application requirements. Carbon coating provides a thin, uniform layer that enhances surface hardness and wear resistance, ideal for protective finishes and lightweight components. Carbon infiltration involves penetrating porous materials with carbon, improving structural integrity and thermal conductivity, making it suitable for high-performance composites and aerospace parts.

Carbon Coating vs Carbon Infiltration Infographic

materialdif.com

materialdif.com