Activated carbon features a highly porous structure designed for adsorption and purification applications, effectively trapping impurities and contaminants. Carbon black consists of fine carbon particles primarily used as a reinforcing filler in rubber products and as a pigment in inks and coatings. The key distinction lies in activated carbon's surface area targeted for filtration, while carbon black is valued for its conductivity and mechanical strength.

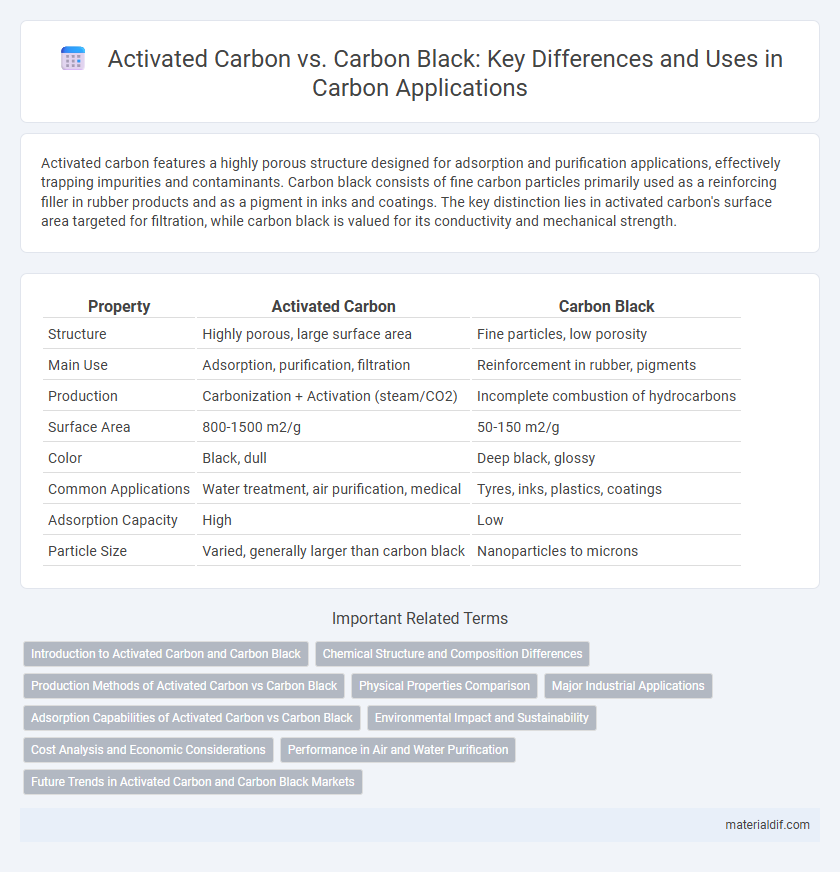

Table of Comparison

| Property | Activated Carbon | Carbon Black |

|---|---|---|

| Structure | Highly porous, large surface area | Fine particles, low porosity |

| Main Use | Adsorption, purification, filtration | Reinforcement in rubber, pigments |

| Production | Carbonization + Activation (steam/CO2) | Incomplete combustion of hydrocarbons |

| Surface Area | 800-1500 m2/g | 50-150 m2/g |

| Color | Black, dull | Deep black, glossy |

| Common Applications | Water treatment, air purification, medical | Tyres, inks, plastics, coatings |

| Adsorption Capacity | High | Low |

| Particle Size | Varied, generally larger than carbon black | Nanoparticles to microns |

Introduction to Activated Carbon and Carbon Black

Activated carbon is a highly porous material primarily used for adsorption and filtration applications due to its large surface area and strong affinity for contaminants. Carbon black is a fine, particulate form of carbon produced by the incomplete combustion of hydrocarbons, commonly utilized as a reinforcing filler in rubber products and as a pigment in inks and paints. Both materials differ significantly in structure, production methods, and industrial uses, with activated carbon emphasizing purification and carbon black focusing on material enhancement.

Chemical Structure and Composition Differences

Activated carbon consists primarily of amorphous carbon with a highly porous structure and a large surface area, featuring numerous oxygen-containing functional groups such as hydroxyl, carbonyl, and carboxyl groups. Carbon black is composed mainly of nearly pure elemental carbon in the form of spheroidal particles with limited surface functionality and minimal porosity. The chemical composition of activated carbon allows for higher adsorption capacity, while carbon black's structure is optimized for reinforcing materials and pigmentation.

Production Methods of Activated Carbon vs Carbon Black

Activated carbon is produced by carbonizing organic materials such as wood, coal, or coconut shells at high temperatures, followed by activation using gases like steam or carbon dioxide to develop its porous structure. In contrast, carbon black is synthesized through the incomplete combustion or thermal decomposition of hydrocarbons, primarily oil or natural gas, resulting in fine particles with high surface area but limited porosity. The distinct production methods impart activated carbon with extensive adsorption capabilities, while carbon black is valued for its reinforcing properties in rubber and pigment applications.

Physical Properties Comparison

Activated carbon exhibits a highly porous structure with a large surface area typically ranging from 500 to 1500 m2/g, enhancing its adsorption capacity, while carbon black has a lower surface area around 50 to 200 m2/g and a more compact particle morphology. Activated carbon particles are irregular and granular or powdered, whereas carbon black consists of finer, spherical particles that tend to aggregate. The density of activated carbon varies between 0.4 to 0.6 g/cm3, compared to carbon black's higher density of approximately 1.8 to 2.1 g/cm3, influencing their application in filtration versus reinforcement and pigmentation.

Major Industrial Applications

Activated carbon is widely used in water purification, air filtration, and medical treatments due to its high porosity and adsorption capacity, effectively removing contaminants and toxins. Carbon black primarily serves as a reinforcing agent in rubber products, especially tires, and as a pigment in inks, coatings, and plastics because of its fine particle size and conductivity. Industrial sectors rely on activated carbon for environmental cleanup and carbon black for enhancing material strength and electrical conductivity.

Adsorption Capabilities of Activated Carbon vs Carbon Black

Activated carbon exhibits superior adsorption capabilities due to its highly porous structure and large surface area, enabling it to capture a wide range of contaminants including gases, chemicals, and organic compounds. Carbon black, primarily used as a reinforcing filler in rubber and pigments, has a lower surface area and limited porosity, resulting in significantly reduced adsorption capacity compared to activated carbon. The microporous texture of activated carbon facilitates efficient removal of pollutants, making it the preferred choice for air and water purification applications.

Environmental Impact and Sustainability

Activated carbon and carbon black differ significantly in environmental impact and sustainability; activated carbon is often produced from renewable biomass sources like coconut shells and wood, making it more eco-friendly. Carbon black, primarily derived from fossil fuel combustion, contributes to higher carbon emissions and environmental pollution. The biodegradability and regeneration capabilities of activated carbon enhance its sustainability compared to the non-renewable, pollutant-heavy production process of carbon black.

Cost Analysis and Economic Considerations

Activated carbon typically incurs higher production costs due to its complex activation processes involving thermal or chemical treatment, which increases its market price compared to carbon black. Carbon black offers a more cost-effective solution with lower manufacturing expenses, primarily derived from incomplete combustion of hydrocarbons, making it preferable for large-scale industrial applications where budget constraints are critical. Economic considerations favor activated carbon in applications requiring high adsorption capacity despite the price premium, whereas carbon black is favored for reinforcement in rubber and pigments due to its affordability.

Performance in Air and Water Purification

Activated carbon exhibits superior adsorption capabilities for air and water purification due to its highly porous structure and large surface area, effectively removing organic compounds, chlorine, and heavy metals. Carbon black, primarily used as a pigment and reinforcing agent, offers limited adsorption performance and is less effective in contaminant removal from air and water. The differences in pore size distribution and surface chemistry make activated carbon the preferred choice for purification applications.

Future Trends in Activated Carbon and Carbon Black Markets

The future trends in activated carbon markets highlight increasing demand for water and air purification driven by stringent environmental regulations and growing industrialization. Carbon black markets exhibit growth fueled by expanding automotive sectors and rising usage in tire manufacturing, alongside innovations in conductive carbon black for electronics. Advancements in sustainable production methods and the development of bio-based activated carbon are set to transform both markets, emphasizing environmental compatibility and performance enhancement.

Activated Carbon vs Carbon Black Infographic

materialdif.com

materialdif.com