Diamond-like carbon (DLC) is an amorphous carbon material with a mix of sp2 and sp3 bonds, offering high hardness, low friction, and excellent wear resistance. Crystalline diamond consists of a highly ordered sp3 carbon lattice, providing superior hardness and thermal conductivity but less flexibility in coating applications. DLC coatings are preferred for protective layers on tools and medical devices due to their smooth surface and toughness, while crystalline diamonds are prized for cutting edges and optical uses.

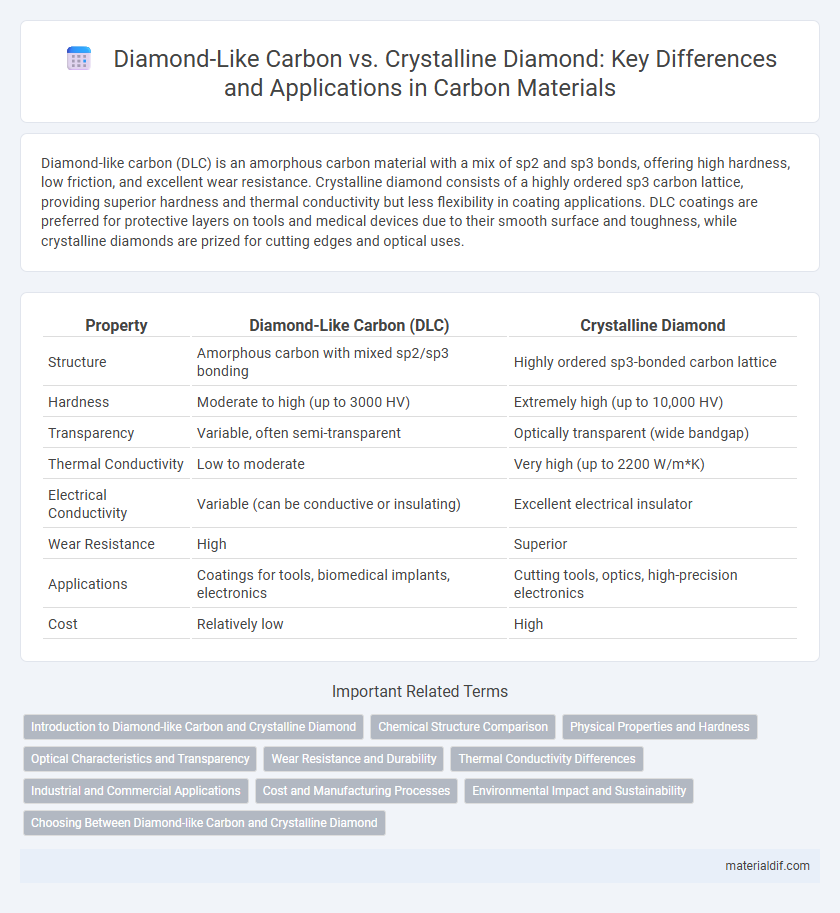

Table of Comparison

| Property | Diamond-Like Carbon (DLC) | Crystalline Diamond |

|---|---|---|

| Structure | Amorphous carbon with mixed sp2/sp3 bonding | Highly ordered sp3-bonded carbon lattice |

| Hardness | Moderate to high (up to 3000 HV) | Extremely high (up to 10,000 HV) |

| Transparency | Variable, often semi-transparent | Optically transparent (wide bandgap) |

| Thermal Conductivity | Low to moderate | Very high (up to 2200 W/m*K) |

| Electrical Conductivity | Variable (can be conductive or insulating) | Excellent electrical insulator |

| Wear Resistance | High | Superior |

| Applications | Coatings for tools, biomedical implants, electronics | Cutting tools, optics, high-precision electronics |

| Cost | Relatively low | High |

Introduction to Diamond-like Carbon and Crystalline Diamond

Diamond-like carbon (DLC) is an amorphous carbon material exhibiting some of the desirable properties of crystalline diamond, such as high hardness, low friction, and chemical inertness, while offering greater flexibility in coating applications. Crystalline diamond, composed of a perfect lattice of carbon atoms arranged in a tetrahedral structure, boasts unmatched hardness, thermal conductivity, and optical clarity. Understanding the differences in atomic structure and resulting physical properties is crucial for selecting DLC or crystalline diamond in industrial, biomedical, and electronic applications.

Chemical Structure Comparison

Diamond-like carbon (DLC) exhibits an amorphous structure composed of a mixture of sp2 and sp3 bonded carbon atoms, creating a non-crystalline network with variable hydrogen content. In contrast, crystalline diamond possesses a highly ordered tetrahedral lattice formed entirely by sp3 hybridized carbon atoms, yielding exceptional hardness and thermal conductivity. These structural differences significantly influence their physical properties and applications in wear resistance and electronic devices.

Physical Properties and Hardness

Diamond-like carbon (DLC) exhibits a combination of high hardness, low friction, and chemical inertness due to its amorphous carbon structure with significant sp3 bonding, whereas crystalline diamond is a pure sp3-bonded carbon lattice known as the hardest natural material with a Vickers hardness of approximately 70-100 GPa. DLC coatings typically have hardness values ranging from 10 to 30 GPa, offering enhanced wear resistance and flexibility compared to the brittle nature of crystalline diamond. The physical properties of DLC, including its lower density and tunable elasticity, make it advantageous for protective coatings, while crystalline diamond excels in applications demanding supreme hardness and thermal conductivity.

Optical Characteristics and Transparency

Diamond-like carbon (DLC) exhibits a broad optical transparency extending from the visible to the infrared spectrum due to its amorphous structure, which minimizes light scattering. Crystalline diamond offers superior optical clarity with a refractive index of approximately 2.42 and exceptional transparency across ultraviolet to far-infrared wavelengths, making it ideal for high-precision optical applications. The absence of grain boundaries in crystalline diamond results in minimal birefringence and high light transmittance, whereas DLC's tunable hydrogen content affects its optical bandgap and transparency.

Wear Resistance and Durability

Diamond-like carbon (DLC) coatings exhibit exceptional wear resistance due to their amorphous structure and high hardness, making them ideal for applications requiring low friction and high durability. Crystalline diamonds possess unparalleled hardness and thermal conductivity, providing superior durability and resistance to abrasion under extreme conditions. While DLC layers offer enhanced toughness and reduced brittleness compared to crystalline diamonds, crystalline diamonds remain the benchmark for the highest wear resistance in cutting and polishing tools.

Thermal Conductivity Differences

Diamond-like carbon (DLC) exhibits significantly lower thermal conductivity compared to crystalline diamond due to its amorphous structure and disordered carbon atoms that scatter phonons more effectively. Crystalline diamond, with its highly ordered carbon lattice, achieves thermal conductivity values exceeding 2000 W/m*K, making it one of the best thermal conductors known. The intrinsic phonon transport efficiency in crystalline diamond enables superior heat dissipation, whereas DLC's structural defects and sp3/sp2 bonding variations limit heat flow.

Industrial and Commercial Applications

Diamond-like carbon (DLC) offers exceptional hardness, low friction, and chemical resistance, making it ideal for industrial coatings on cutting tools, automotive components, and medical devices to enhance wear life and reduce maintenance. Crystalline diamond, known for its unparalleled thermal conductivity and extreme hardness, is extensively used in high-precision cutting, drilling, and grinding applications across aerospace, semiconductor, and oil drilling industries. The choice between DLC and crystalline diamond depends on the specific performance requirements, cost considerations, and operational environments of commercial applications.

Cost and Manufacturing Processes

Diamond-like carbon (DLC) coatings offer a cost-effective alternative to crystalline diamond due to lower raw material expenses and simpler deposition techniques such as chemical vapor deposition (CVD) and sputtering. Crystalline diamond manufacturing involves high-pressure high-temperature (HPHT) or advanced CVD methods that require substantial energy and specialized equipment, significantly increasing production costs. DLC's versatility in application and rapid processing time make it favorable for industrial uses where budget constraints prevail without sacrificing hardness and wear resistance.

Environmental Impact and Sustainability

Diamond-like carbon (DLC) coatings offer significant environmental benefits over crystalline diamonds due to their synthetic production, which avoids mining-related ecological damage and reduces carbon emissions. DLC materials are more sustainable as they require less energy-intensive processes and can be applied to extend the lifespan of industrial components, lowering overall resource consumption. In contrast, the extraction of crystalline diamonds involves extensive land disruption, water usage, and greenhouse gas emissions, raising concerns about their long-term environmental impact.

Choosing Between Diamond-like Carbon and Crystalline Diamond

Diamond-like carbon (DLC) offers exceptional hardness, low friction, and chemical inertness, making it ideal for protective coatings in industrial applications where wear resistance is critical. Crystalline diamond, composed of a well-ordered lattice structure, provides unmatched thermal conductivity and optical clarity, preferred in cutting tools and high-precision optics. Selecting between DLC and crystalline diamond depends on the application's specific needs for durability, thermal management, and cost-effectiveness.

Diamond-like carbon vs Crystalline diamond Infographic

materialdif.com

materialdif.com