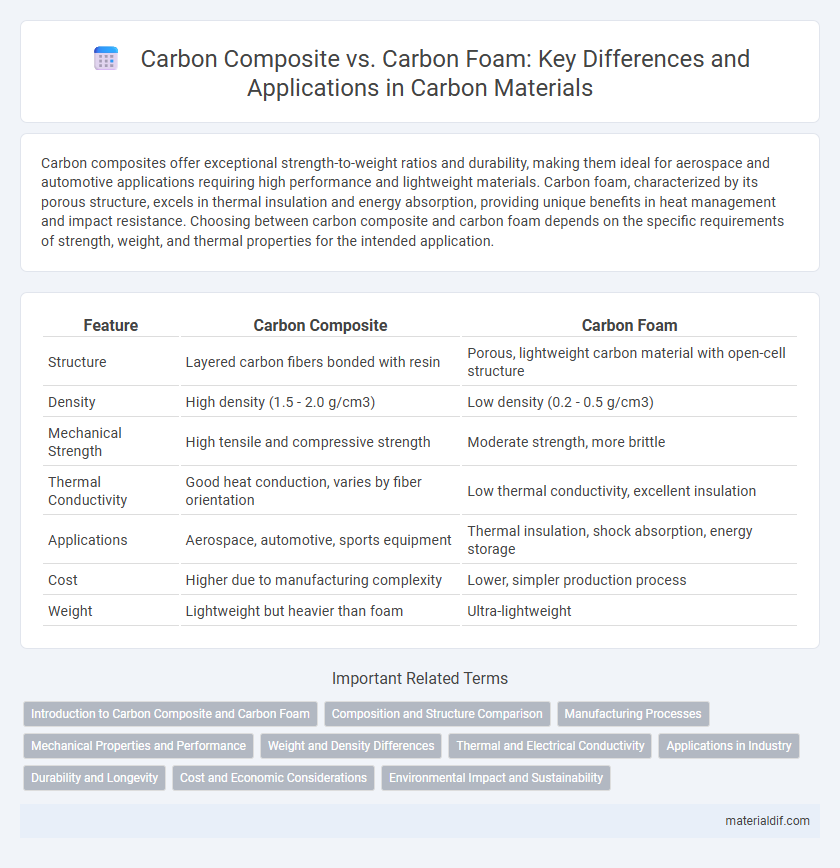

Carbon composites offer exceptional strength-to-weight ratios and durability, making them ideal for aerospace and automotive applications requiring high performance and lightweight materials. Carbon foam, characterized by its porous structure, excels in thermal insulation and energy absorption, providing unique benefits in heat management and impact resistance. Choosing between carbon composite and carbon foam depends on the specific requirements of strength, weight, and thermal properties for the intended application.

Table of Comparison

| Feature | Carbon Composite | Carbon Foam |

|---|---|---|

| Structure | Layered carbon fibers bonded with resin | Porous, lightweight carbon material with open-cell structure |

| Density | High density (1.5 - 2.0 g/cm3) | Low density (0.2 - 0.5 g/cm3) |

| Mechanical Strength | High tensile and compressive strength | Moderate strength, more brittle |

| Thermal Conductivity | Good heat conduction, varies by fiber orientation | Low thermal conductivity, excellent insulation |

| Applications | Aerospace, automotive, sports equipment | Thermal insulation, shock absorption, energy storage |

| Cost | Higher due to manufacturing complexity | Lower, simpler production process |

| Weight | Lightweight but heavier than foam | Ultra-lightweight |

Introduction to Carbon Composite and Carbon Foam

Carbon composites consist of carbon fibers embedded in a polymer matrix, providing exceptional strength-to-weight ratios and high stiffness, making them ideal for aerospace, automotive, and sporting goods applications. Carbon foam, a porous material made from carbon with high surface area and thermal conductivity, is valued for its lightweight structure and efficient heat dissipation properties, widely used in thermal management and filtration systems. Both materials leverage carbon's unique properties but serve different functions based on their structural characteristics and application requirements.

Composition and Structure Comparison

Carbon composites consist of carbon fibers embedded within a polymer resin matrix, offering high tensile strength and lightweight properties due to the aligned fiber structure. Carbon foam is a porous, three-dimensional carbon network with a low density and high surface area, characterized by its open-cell or closed-cell morphology that provides excellent thermal insulation and energy absorption. The primary structural difference lies in carbon composites' layered fiber orientation versus carbon foam's interconnected porous architecture, influencing their respective mechanical and thermal performance.

Manufacturing Processes

Carbon composites are typically manufactured through a layering process involving carbon fiber sheets impregnated with resin, followed by curing under heat and pressure in an autoclave or press, resulting in lightweight, high-strength materials ideal for aerospace and automotive industries. In contrast, carbon foam is produced by pyrolyzing organic precursors or polymer foams under controlled conditions to create a porous, lightweight structure with excellent thermal and electrical conductivity properties, widely used in thermal management and filtration systems. The complexity of composite layup and resin curing contrasts with the foam's pyrolysis and foaming techniques, highlighting distinct manufacturing challenges and applications.

Mechanical Properties and Performance

Carbon composites boast exceptional tensile strength and stiffness, making them ideal for high-performance structural applications demanding durability and lightweight characteristics. Carbon foam, characterized by its porous structure, excels in impact absorption and thermal insulation but offers lower mechanical strength compared to solid composites. The choice between carbon composite and carbon foam depends on balancing mechanical performance requirements with weight reduction and energy absorption needs.

Weight and Density Differences

Carbon composites typically offer a higher strength-to-weight ratio compared to carbon foam, making them lighter for structural applications. Carbon foam is characterized by its low density and porous structure, resulting in significantly reduced weight but lower mechanical strength. The density of carbon composites generally ranges from 1.5 to 2.0 g/cm3, while carbon foam densities can be as low as 0.2 to 0.6 g/cm3, highlighting the substantial difference in weight and structural properties.

Thermal and Electrical Conductivity

Carbon composites exhibit superior electrical conductivity due to their densely packed carbon fibers, making them ideal for applications requiring efficient current flow and electromagnetic interference shielding. Carbon foam, characterized by its porous structure, offers lower thermal conductivity but enhanced thermal insulation, suitable for heat management in aerospace and electronics cooling. The choice between carbon composite and carbon foam hinges on balancing electrical conductivity needs with thermal insulation performance.

Applications in Industry

Carbon composites are extensively used in aerospace and automotive industries due to their high strength-to-weight ratio and excellent fatigue resistance, enhancing vehicle performance and fuel efficiency. Carbon foam finds applications in thermal management and energy storage systems, offering superior heat dissipation and lightweight structural support in electronics and battery technologies. Industrial sectors leverage carbon composite materials for structural components, while carbon foam is preferred for insulation and cushioning in advanced manufacturing processes.

Durability and Longevity

Carbon composite materials exhibit superior durability due to their high tensile strength and resistance to fatigue, making them ideal for structural applications requiring long-term performance. Carbon foam, while lightweight and possessing excellent thermal insulation properties, typically offers lower mechanical strength and may degrade faster under repeated stress or harsh environmental conditions. The inherent fiber reinforcement in carbon composites significantly extends their longevity compared to the porous structure of carbon foam, which can be more susceptible to wear and damage over time.

Cost and Economic Considerations

Carbon composites generally incur higher production costs due to complex manufacturing processes and expensive raw materials, making them less economical for large-scale applications. Carbon foam offers a more cost-effective alternative with simpler fabrication and greater scalability, especially in thermal insulation and lightweight structural uses. Economic considerations favor carbon foam when balancing performance and budget constraints in industries like automotive and aerospace.

Environmental Impact and Sustainability

Carbon composites exhibit high strength-to-weight ratios and long durability, reducing material consumption and vehicle emissions over their lifecycle, but their complex manufacturing and limited recyclability pose environmental challenges. Carbon foam offers superior thermal insulation and potential for reuse in energy-efficient building materials, enhancing sustainability through lower energy demand and recyclability. Evaluating carbon composite versus carbon foam requires balancing performance benefits with end-of-life environmental impacts to optimize sustainable applications.

Carbon Composite vs Carbon Foam Infographic

materialdif.com

materialdif.com