Carbon mat offers a denser and more rigid structure, making it ideal for applications requiring high mechanical strength and durability. Carbon felt is more porous and flexible, providing superior insulation and efficient gas diffusion in thermal and electrochemical systems. Selecting between carbon mat and carbon felt depends on the specific requirements of conductivity, strength, and permeability in the intended use.

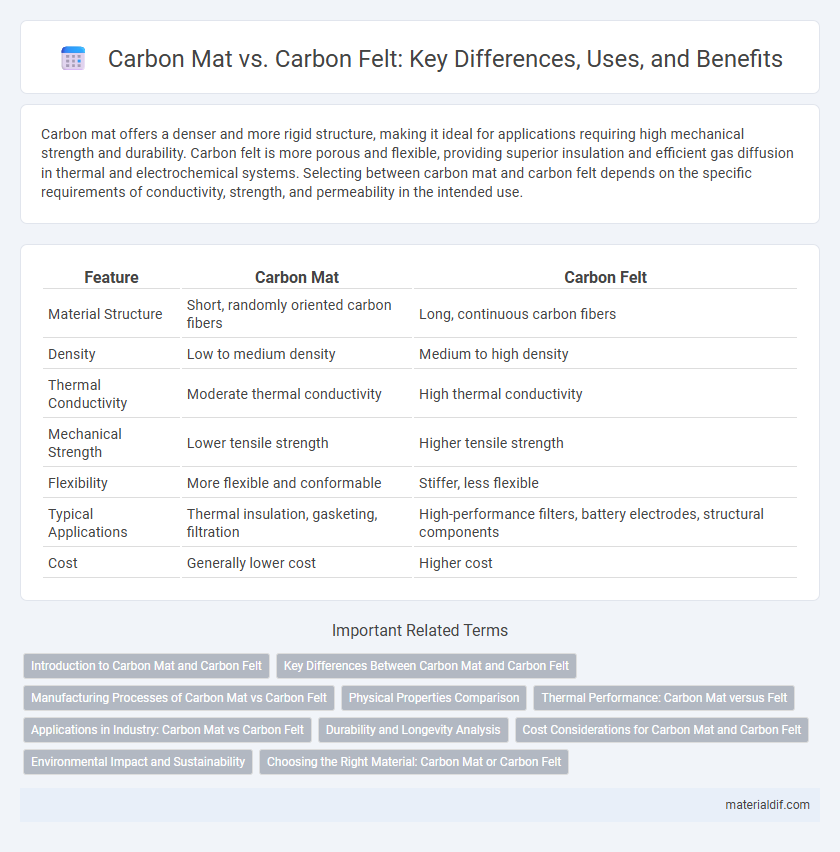

Table of Comparison

| Feature | Carbon Mat | Carbon Felt |

|---|---|---|

| Material Structure | Short, randomly oriented carbon fibers | Long, continuous carbon fibers |

| Density | Low to medium density | Medium to high density |

| Thermal Conductivity | Moderate thermal conductivity | High thermal conductivity |

| Mechanical Strength | Lower tensile strength | Higher tensile strength |

| Flexibility | More flexible and conformable | Stiffer, less flexible |

| Typical Applications | Thermal insulation, gasketing, filtration | High-performance filters, battery electrodes, structural components |

| Cost | Generally lower cost | Higher cost |

Introduction to Carbon Mat and Carbon Felt

Carbon mat consists of dense carbon fibers bonded into a flexible sheet, offering high thermal conductivity and structural integrity in insulation and filtration applications. Carbon felt features a less dense, more porous structure with random fiber orientation, providing superior surface area and enhanced adsorption properties for use in catalyst support and high-temperature gaskets. Both materials serve critical roles in industrial processes, with carbon mat favored for mechanical strength and carbon felt chosen for its permeability and thermal insulation performance.

Key Differences Between Carbon Mat and Carbon Felt

Carbon mat exhibits a denser fiber arrangement with a smooth surface, providing superior mechanical strength and rigidity compared to carbon felt. Carbon felt features a more open, porous structure with longer fibers, enhancing its thermal insulation and filtration capabilities. These key differences make carbon mat ideal for composite reinforcement, while carbon felt is preferred for applications requiring high-temperature resistance and absorbency.

Manufacturing Processes of Carbon Mat vs Carbon Felt

Carbon mat manufacturing involves the formation of continuous carbon fibers or chopped strands laid in random or oriented mats, followed by resin impregnation and curing to achieve structural integrity. Carbon felt, on the other hand, is produced through the entanglement of short carbon fibers using needle-punching or air-laying techniques, creating a highly porous and flexible material. The primary difference in manufacturing lies in carbon mat's emphasis on fiber alignment and resin bonding versus carbon felt's focus on fiber entanglement and porous structure.

Physical Properties Comparison

Carbon mat exhibits a denser, more uniform structure with higher tensile strength and rigidity compared to carbon felt, which has a more porous, flexible texture ideal for insulation. The thermal conductivity of carbon mat is generally lower due to its compact arrangement, while carbon felt offers superior heat resistance and cushioning because of its open, fibrous network. Both materials possess excellent chemical stability and high-temperature tolerance but differ significantly in mechanical durability and surface area.

Thermal Performance: Carbon Mat versus Felt

Carbon felt exhibits superior thermal insulation due to its porous structure that traps heat effectively, making it ideal for high-temperature applications. Carbon mat, while less insulating, offers better thermal conductivity and structural strength, providing efficient heat distribution and mechanical stability. Optimal use depends on balancing thermal retention needs with mechanical support requirements in industrial processes.

Applications in Industry: Carbon Mat vs Carbon Felt

Carbon mat offers superior mechanical strength and uniform thickness, making it ideal for high-temperature insulation in industrial furnaces and thermal protection in aerospace components. Carbon felt provides excellent porosity and flexibility, which enhances filtration efficiency and electrochemical performance in fuel cells and battery electrodes. Industries favor carbon mat for structural support applications while carbon felt excels in catalytic support and gas diffusion layers.

Durability and Longevity Analysis

Carbon felt exhibits superior durability and longevity compared to carbon mat due to its woven fiber structure, which enhances mechanical strength and resistance to thermal degradation. Carbon felt maintains structural integrity under high-temperature and corrosive environments, making it ideal for long-term industrial applications. In contrast, carbon mat typically has lower tensile strength and faster wear rates, reducing its lifespan in demanding conditions.

Cost Considerations for Carbon Mat and Carbon Felt

Carbon mat typically offers a lower initial cost compared to carbon felt due to simpler manufacturing processes and reduced material density, making it a more budget-friendly option for large-scale applications. Carbon felt, however, involves higher production costs because of its intricate weaving and superior structural properties, which can justify the investment in scenarios requiring enhanced durability and thermal performance. When evaluating cost considerations, it is essential to balance the upfront expenditure of carbon felt against its longer lifespan and potential savings in maintenance and replacement.

Environmental Impact and Sustainability

Carbon mat, produced through controlled fiber alignment, offers superior durability and longer lifespan compared to carbon felt, reducing waste and resource consumption over time. Carbon felt, characterized by its loosely woven fibers, tends to degrade faster and often requires more frequent replacement, increasing environmental impact. Choosing carbon mat supports sustainability by minimizing raw material usage and enhancing energy efficiency during production and application.

Choosing the Right Material: Carbon Mat or Carbon Felt

Choosing between carbon mat and carbon felt depends on the specific application requirements, as carbon mat offers higher structural integrity and is ideal for load-bearing components, while carbon felt provides superior thermal insulation and flexibility for high-temperature environments. Carbon mat's woven structure enhances mechanical strength and impact resistance, making it suitable for composite manufacturing and reinforcement purposes. In contrast, carbon felt's non-woven, porous texture excels in filtration, heat shield systems, and energy storage applications where lightweight and thermal management are critical.

Carbon mat vs Carbon felt Infographic

materialdif.com

materialdif.com