Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, offers exceptional electrical conductivity and mechanical strength, making it ideal for advanced electronics and composite materials. Carbon aerogel, a porous and lightweight form of carbon, excels in applications requiring high surface area and low density, such as energy storage and environmental cleanup. While graphene provides superior conductivity and tensile strength, carbon aerogels stand out for their insulating properties and structural versatility.

Table of Comparison

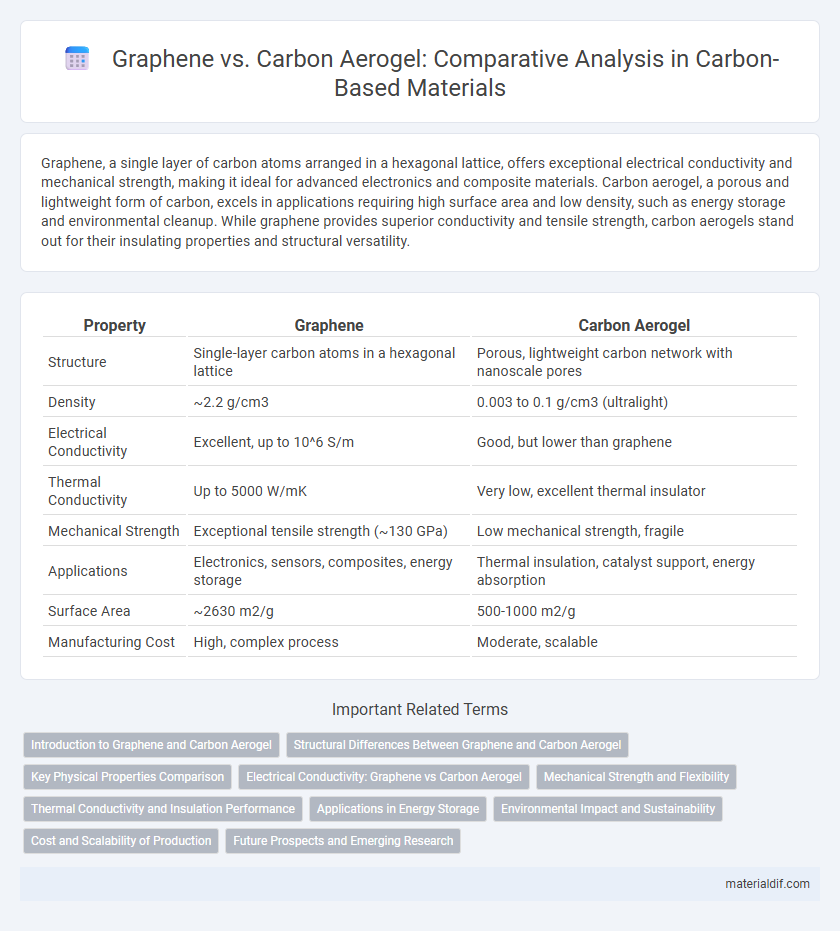

| Property | Graphene | Carbon Aerogel |

|---|---|---|

| Structure | Single-layer carbon atoms in a hexagonal lattice | Porous, lightweight carbon network with nanoscale pores |

| Density | ~2.2 g/cm3 | 0.003 to 0.1 g/cm3 (ultralight) |

| Electrical Conductivity | Excellent, up to 10^6 S/m | Good, but lower than graphene |

| Thermal Conductivity | Up to 5000 W/mK | Very low, excellent thermal insulator |

| Mechanical Strength | Exceptional tensile strength (~130 GPa) | Low mechanical strength, fragile |

| Applications | Electronics, sensors, composites, energy storage | Thermal insulation, catalyst support, energy absorption |

| Surface Area | ~2630 m2/g | 500-1000 m2/g |

| Manufacturing Cost | High, complex process | Moderate, scalable |

Introduction to Graphene and Carbon Aerogel

Graphene, a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice, exhibits exceptional electrical conductivity, mechanical strength, and surface area. Carbon aerogel, a lightweight porous material composed predominantly of carbon, is known for its ultra-low density and high thermal insulation properties. Both materials leverage the versatile nature of carbon but serve distinctly different applications due to their unique structural characteristics.

Structural Differences Between Graphene and Carbon Aerogel

Graphene consists of a single layer of carbon atoms arranged in a two-dimensional hexagonal lattice, resulting in exceptional electrical conductivity and mechanical strength. Carbon aerogel, on the other hand, is a highly porous, three-dimensional network of carbon nanoparticles with a low density and large surface area, enabling superior thermal insulation and adsorption properties. The fundamental structural difference lies in graphene's atomically thin planar sheets versus the interconnected, sponge-like matrix of carbon aerogels.

Key Physical Properties Comparison

Graphene exhibits exceptional electrical conductivity, high mechanical strength with a tensile strength of approximately 130 GPa, and a surface area up to 2,630 m2/g. Carbon aerogel, characterized by its ultra-low density ranging from 0.003 to 0.1 g/cm3 and high porosity (over 90%), offers superior thermal insulation and energy absorption capabilities. Both materials possess unique advantages, with graphene excelling in strength and conductivity, while carbon aerogel provides lightweight structural support and thermal management.

Electrical Conductivity: Graphene vs Carbon Aerogel

Graphene exhibits exceptional electrical conductivity with charge carrier mobility reaching up to 200,000 cm2/V*s, making it one of the most conductive carbon materials available. In contrast, carbon aerogel has significantly lower electrical conductivity, typically ranging from 1 to 100 S/m, due to its porous structure and limited electron pathways. The superior conductivity of graphene stems from its two-dimensional hexagonal lattice of sp2-bonded carbon atoms, facilitating rapid electron transport unlike the three-dimensional, highly porous network of carbon aerogels.

Mechanical Strength and Flexibility

Graphene exhibits exceptional mechanical strength with a tensile strength of approximately 130 GPa and remarkable flexibility due to its single-atom thickness, allowing it to bend without breaking. Carbon aerogel, while significantly lighter and highly porous, offers moderate mechanical strength with compressive strengths typically below 10 MPa but compensates with excellent elasticity and resilience under compressive loads. The stark contrast between graphene's atomic-scale robustness and carbon aerogel's macro-porous structure defines their distinct applications in flexible electronics and lightweight structural materials, respectively.

Thermal Conductivity and Insulation Performance

Graphene exhibits exceptionally high thermal conductivity, reaching up to 5300 W/mK, making it ideal for efficient heat dissipation applications. In contrast, carbon aerogel demonstrates ultra-low thermal conductivity, often below 0.015 W/mK, providing superior insulation performance due to its porous, lightweight structure. The distinct thermal properties of graphene and carbon aerogel enable their targeted use in thermal management, with graphene enhancing conductivity and carbon aerogel maximizing insulation.

Applications in Energy Storage

Graphene exhibits exceptional electrical conductivity and high surface area, making it ideal for enhancing supercapacitors and lithium-ion batteries by improving charge storage capacity and charge-discharge rates. Carbon aerogels offer lightweight, porous structures with excellent thermal stability and conductivity, suitable for electrode materials in energy storage systems requiring rapid ion transport and mechanical flexibility. Both materials accelerate advancements in energy storage technologies, with graphene excelling in power density and carbon aerogel in structural versatility for flexible energy devices.

Environmental Impact and Sustainability

Graphene demonstrates exceptional strength and conductivity with minimal environmental footprint due to its efficient production methods using carbon sources, making it a sustainable material for advanced applications. Carbon aerogel, while lightweight and porous, often requires energy-intensive synthesis processes involving toxic chemicals, leading to higher environmental costs and less sustainability. The development of eco-friendly production techniques for both materials remains critical to maximizing their benefits while minimizing ecological impact.

Cost and Scalability of Production

Graphene production involves complex processes such as chemical vapor deposition and exfoliation, resulting in high costs and limited scalability, especially for large-scale industrial applications. Carbon aerogels benefit from more straightforward synthesis methods like sol-gel polymerization followed by supercritical drying, enabling lower production costs and easier scalability while maintaining high surface area and porosity. Consequently, carbon aerogels are often preferred for commercial applications requiring bulk materials, whereas graphene remains more suited for high-performance, niche markets due to current production constraints.

Future Prospects and Emerging Research

Graphene exhibits exceptional electrical conductivity and mechanical strength, positioning it as a leading material for next-generation electronics and energy storage systems. Carbon aerogel's ultra-lightweight, porous structure drives innovations in environmental applications such as water purification and supercapacitors. Emerging research explores hybrid composites integrating graphene with carbon aerogels to enhance structural stability while maximizing performance in advanced energy and sensor technologies.

Graphene vs Carbon aerogel Infographic

materialdif.com

materialdif.com