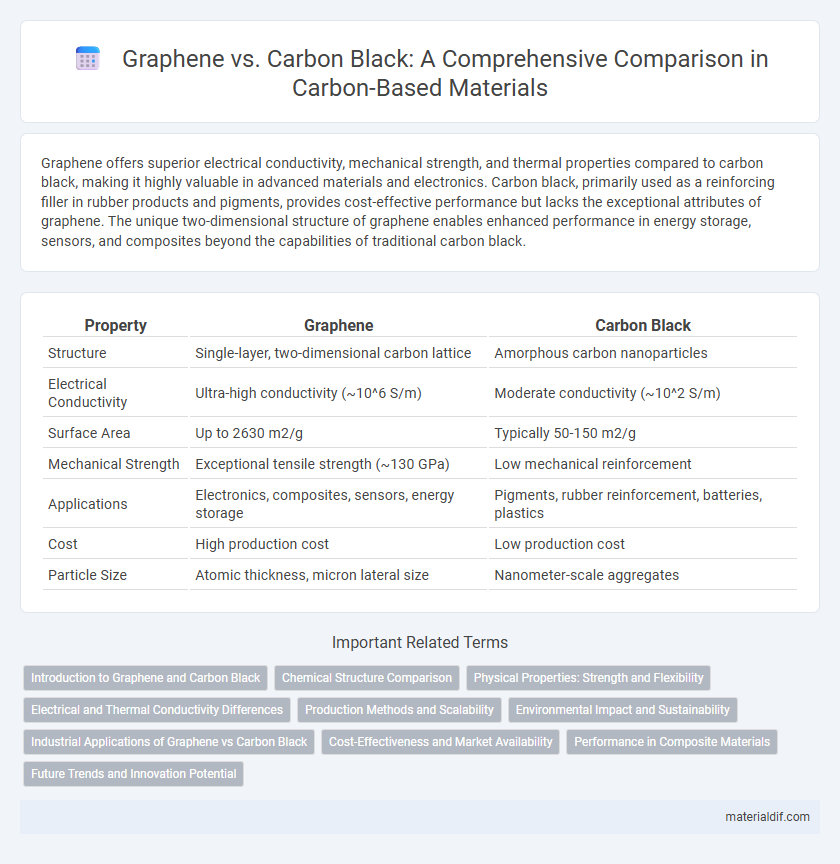

Graphene offers superior electrical conductivity, mechanical strength, and thermal properties compared to carbon black, making it highly valuable in advanced materials and electronics. Carbon black, primarily used as a reinforcing filler in rubber products and pigments, provides cost-effective performance but lacks the exceptional attributes of graphene. The unique two-dimensional structure of graphene enables enhanced performance in energy storage, sensors, and composites beyond the capabilities of traditional carbon black.

Table of Comparison

| Property | Graphene | Carbon Black |

|---|---|---|

| Structure | Single-layer, two-dimensional carbon lattice | Amorphous carbon nanoparticles |

| Electrical Conductivity | Ultra-high conductivity (~10^6 S/m) | Moderate conductivity (~10^2 S/m) |

| Surface Area | Up to 2630 m2/g | Typically 50-150 m2/g |

| Mechanical Strength | Exceptional tensile strength (~130 GPa) | Low mechanical reinforcement |

| Applications | Electronics, composites, sensors, energy storage | Pigments, rubber reinforcement, batteries, plastics |

| Cost | High production cost | Low production cost |

| Particle Size | Atomic thickness, micron lateral size | Nanometer-scale aggregates |

Introduction to Graphene and Carbon Black

Graphene is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice, exhibiting exceptional electrical conductivity, mechanical strength, and thermal properties. Carbon black consists of fine amorphous carbon particles produced by incomplete combustion of hydrocarbons, primarily used as a reinforcing filler in rubber and pigments in inks and coatings. Both materials leverage carbon's versatile bonding but differ significantly in structure, applications, and performance characteristics.

Chemical Structure Comparison

Graphene consists of a single layer of sp2-hybridized carbon atoms arranged in a two-dimensional honeycomb lattice, providing exceptional electrical conductivity and mechanical strength. Carbon black comprises quasi-spherical particles with a largely amorphous, polycrystalline structure, exhibiting sp2 and sp3 hybridizations that contribute to lower conductivity and diverse surface chemistry. The distinct chemical structures of graphene and carbon black influence their performance in applications such as energy storage, catalysis, and composite materials.

Physical Properties: Strength and Flexibility

Graphene exhibits exceptional strength with a tensile strength of approximately 130 GPa, making it one of the strongest known materials, while carbon black typically has lower tensile strength due to its particulate nature. Graphene's single-layer atomic structure provides remarkable flexibility, allowing it to bend without breaking, unlike carbon black, which is rigid and brittle. These contrasting physical properties make graphene ideal for advanced composite materials requiring both high strength and flexibility.

Electrical and Thermal Conductivity Differences

Graphene exhibits exceptional electrical conductivity, surpassing carbon black significantly due to its two-dimensional lattice of sp2-bonded carbon atoms enabling electron mobility up to 200,000 cm2/Vs. Its thermal conductivity exceeds 4,000 W/mK, far higher than carbon black's approximate 0.1-0.5 W/mK, attributed to graphene's ordered crystalline structure facilitating efficient phonon transport. These property differences make graphene highly suitable for advanced electronic and thermal management applications compared to traditional carbon black fillers.

Production Methods and Scalability

Graphene production primarily relies on methods such as chemical vapor deposition (CVD), liquid phase exfoliation, and epitaxial growth, which offer high quality but face challenges in large-scale scalability due to complexity and cost. Carbon black is produced through furnace black and thermal black processes that are highly scalable and economically efficient, enabling mass production for industrial applications. The scalability of carbon black production significantly outpaces graphene, though advances in roll-to-roll CVD and other innovative techniques aim to improve graphene scalability for commercial use.

Environmental Impact and Sustainability

Graphene exhibits superior environmental benefits compared to carbon black due to its higher efficiency and lower material consumption in industrial applications. Carbon black production involves significant greenhouse gas emissions and reliance on fossil fuels, whereas graphene synthesis methods increasingly leverage sustainable processes such as chemical vapor deposition and biomass precursors. The sustainability of graphene is further enhanced by its potential to replace carbon black in tires and batteries, reducing the ecological footprint associated with traditional carbon-based materials.

Industrial Applications of Graphene vs Carbon Black

Graphene exhibits superior electrical conductivity, mechanical strength, and thermal stability compared to carbon black, making it ideal for advanced electronics, energy storage devices, and composite materials in automotive and aerospace industries. Carbon black remains widely used as a cost-effective reinforcing agent in tires, rubber products, and pigments, offering excellent abrasion resistance and UV protection. Industrial applications increasingly favor graphene for high-performance devices while carbon black dominates traditional manufacturing processes due to its scalability and established supply chains.

Cost-Effectiveness and Market Availability

Graphene offers superior conductivity and strength compared to carbon black, but its production costs remain significantly higher, limiting widespread adoption in cost-sensitive applications. Carbon black, with its established large-scale manufacturing infrastructure, provides a more affordable and readily available option for industries such as tires, coatings, and plastics. Market availability of carbon black continues to dominate due to lower prices and mature supply chains, while graphene's niche use grows slowly as production technologies evolve and economies of scale improve.

Performance in Composite Materials

Graphene exhibits superior mechanical strength, electrical conductivity, and thermal stability compared to carbon black in composite materials, enhancing overall performance. Its two-dimensional structure enables better load transfer and reinforcement, resulting in composites with improved durability and flexibility. Carbon black primarily aims to improve conductivity and UV protection but falls short of graphene's multifunctional enhancements in advanced composites.

Future Trends and Innovation Potential

Graphene exhibits superior electrical conductivity, mechanical strength, and thermal stability compared to carbon black, positioning it as a key material in next-generation electronics, energy storage, and composite materials. Emerging research focuses on scalable, cost-effective production methods for graphene to replace carbon black in applications such as battery electrodes and conductive inks. The innovation potential of graphene lies in its ability to enable ultrahigh-performance devices and sustainable materials, driving future trends in nanotechnology and green manufacturing.

Graphene vs Carbon black Infographic

materialdif.com

materialdif.com