Carbon fiber offers high strength and lightweight properties ideal for aerospace and automotive industries, while carbon nanotubes provide superior electrical conductivity and tensile strength at the nanoscale. The unique molecular structure of carbon nanotubes enables applications in nanotechnology and advanced electronics that carbon fiber cannot achieve. Both materials leverage carbon's versatility, but carbon nanotubes outperform carbon fiber in terms of mechanical strength and electrical performance on a microscopic level.

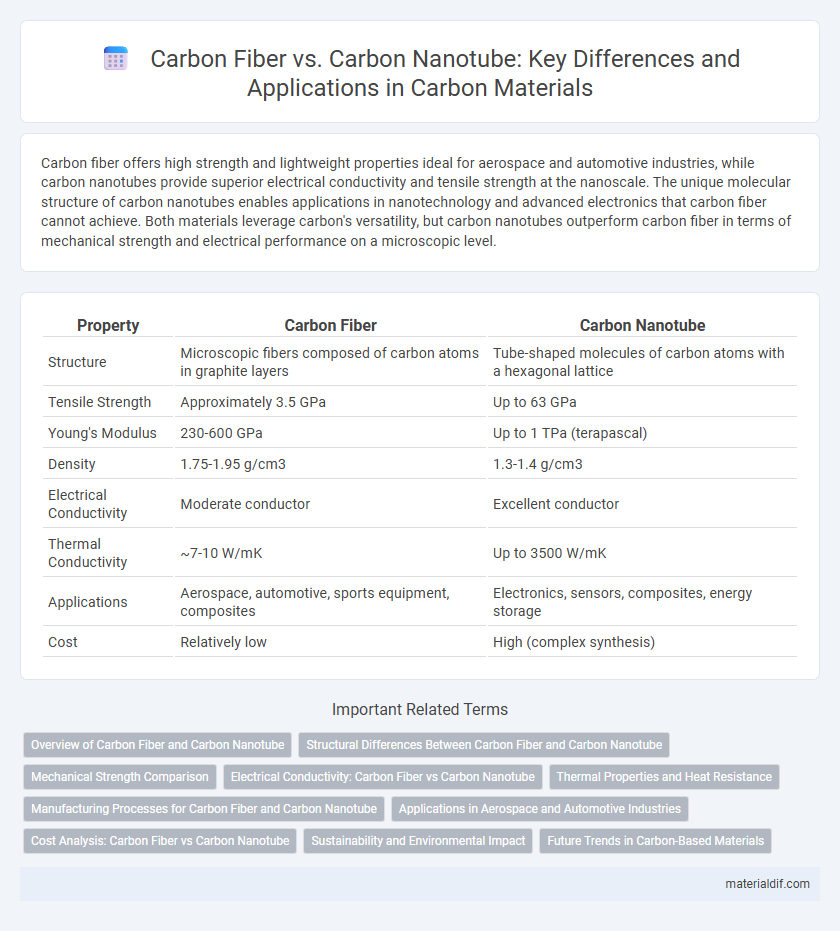

Table of Comparison

| Property | Carbon Fiber | Carbon Nanotube |

|---|---|---|

| Structure | Microscopic fibers composed of carbon atoms in graphite layers | Tube-shaped molecules of carbon atoms with a hexagonal lattice |

| Tensile Strength | Approximately 3.5 GPa | Up to 63 GPa |

| Young's Modulus | 230-600 GPa | Up to 1 TPa (terapascal) |

| Density | 1.75-1.95 g/cm3 | 1.3-1.4 g/cm3 |

| Electrical Conductivity | Moderate conductor | Excellent conductor |

| Thermal Conductivity | ~7-10 W/mK | Up to 3500 W/mK |

| Applications | Aerospace, automotive, sports equipment, composites | Electronics, sensors, composites, energy storage |

| Cost | Relatively low | High (complex synthesis) |

Overview of Carbon Fiber and Carbon Nanotube

Carbon fiber consists of thin, strong crystalline filaments of carbon tightly woven to form a lightweight material with high tensile strength and excellent rigidity, extensively used in aerospace, automotive, and sporting goods industries. Carbon nanotubes are cylindrical nanostructures made of rolled graphene sheets with extraordinary mechanical, electrical, and thermal properties, often applied in nanotechnology, electronics, and advanced composite materials. The major distinction lies in scale and structure: carbon fiber is a macroscopic material with bulk mechanical strength, while carbon nanotubes exhibit exceptional nanoscale properties that enhance composites and electronic components.

Structural Differences Between Carbon Fiber and Carbon Nanotube

Carbon fiber consists of long, thin strands of carbon atoms bonded in a hexagonal lattice, providing high tensile strength and rigidity due to its micro-scale diameter. Carbon nanotubes are cylindrical nanostructures formed by rolling a single layer of graphene into a tube, resulting in exceptional mechanical properties and electrical conductivity at the nanoscale. The key structural difference lies in the scale and arrangement; carbon fibers are macro-scale fibers with crystalline carbon structures, whereas carbon nanotubes exhibit a seamless, hollow tube formation with single or multiple graphene layers enhancing their unique characteristics.

Mechanical Strength Comparison

Carbon fiber exhibits high tensile strength around 3,500 MPa, making it widely used in aerospace and automotive industries for structural reinforcement. Carbon nanotubes possess exceptional mechanical strength, with tensile strength exceeding 60,000 MPa and Young's modulus up to 1 TPa, surpassing carbon fiber by an order of magnitude. The superior strength-to-weight ratio of carbon nanotubes enables their application in next-generation composite materials requiring ultra-high mechanical performance.

Electrical Conductivity: Carbon Fiber vs Carbon Nanotube

Carbon nanotubes exhibit significantly higher electrical conductivity than carbon fibers due to their unique cylindrical nanostructure and exceptional electron mobility. Carbon fibers, composed of graphitized carbon, provide moderate conductivity suitable for structural applications but fall short in nanoelectronics and high-frequency devices. The intrinsic conductive properties of carbon nanotubes enable their widespread use in advanced sensors, flexible electronics, and energy storage technologies.

Thermal Properties and Heat Resistance

Carbon nanotubes exhibit superior thermal conductivity, reaching values up to 3000 W/mK, significantly outperforming carbon fiber, which typically ranges from 8 to 100 W/mK. The exceptional heat resistance of carbon nanotubes, withstanding temperatures above 2800degC in vacuum, contrasts with carbon fibers that degrade around 1500degC. This makes carbon nanotubes highly advantageous for applications requiring advanced thermal management and extreme heat tolerance.

Manufacturing Processes for Carbon Fiber and Carbon Nanotube

Carbon fiber manufacturing involves the controlled pyrolysis of precursor materials such as polyacrylonitrile (PAN) or pitch, followed by stabilization, carbonization, and surface treatment to enhance fiber strength and bonding properties. Carbon nanotube synthesis typically employs chemical vapor deposition (CVD), arc discharge, or laser ablation techniques, allowing the formation of cylindrical graphene structures with superior mechanical and electrical properties. Both processes require precise temperature and environmental controls to optimize the microstructure and performance characteristics of the resulting carbon-based materials.

Applications in Aerospace and Automotive Industries

Carbon fiber offers high strength-to-weight ratio and excellent fatigue resistance, making it ideal for aerospace structures, aircraft components, and automotive body panels that require durability and lightness. Carbon nanotubes, with superior tensile strength and electrical conductivity at the nanoscale, are increasingly integrated into composite materials to enhance mechanical performance and enable advanced sensing or electromagnetic shielding in aerospace and automotive applications. Both materials contribute to weight reduction and fuel efficiency improvements, crucial for aircraft and high-performance vehicle design.

Cost Analysis: Carbon Fiber vs Carbon Nanotube

Carbon fiber offers a more cost-effective solution compared to carbon nanotubes, with production costs significantly lower due to established manufacturing processes and raw material availability. Carbon nanotubes, despite superior mechanical and electrical properties, face high production expenses and scalability issues, limiting their widespread industrial adoption. Cost analysis highlights carbon fiber as the preferred material for large-scale applications, whereas carbon nanotubes remain specialized and cost-prohibitive for mass-market uses.

Sustainability and Environmental Impact

Carbon fiber is widely praised for its high strength-to-weight ratio but involves energy-intensive production processes that contribute to significant carbon emissions and challenges in recycling. In contrast, carbon nanotubes offer enhanced mechanical and electrical properties at the nanoscale with potential for lower material usage, yet their environmental impact remains uncertain due to difficulties in large-scale, eco-friendly manufacturing and unknown toxicity effects. Sustainable advancements focus on developing bio-based precursors and greener synthesis methods to reduce the ecological footprint of both carbon fiber and carbon nanotube technologies.

Future Trends in Carbon-Based Materials

Carbon fiber maintains dominance in aerospace and automotive industries due to its high strength-to-weight ratio and cost-effectiveness, but carbon nanotubes exhibit superior electrical conductivity and mechanical strength at the nanoscale, driving research towards hybrid composites. Advances in carbon nanotube synthesis and alignment techniques promise enhanced material performance, enabling breakthroughs in energy storage, flexible electronics, and lightweight structural applications. Future trends emphasize integrating carbon nanotubes with carbon fibers to develop multifunctional materials that combine durability, conductivity, and thermal management for next-generation technology.

Carbon fiber vs Carbon nanotube Infographic

materialdif.com

materialdif.com