Graphitized carbon exhibits a well-ordered crystalline structure, resulting in higher electrical conductivity and greater thermal stability compared to amorphous carbon, which lacks long-range order and contains numerous defects. The enhanced structural arrangement in graphitized carbon makes it ideal for applications requiring durability and efficient electron transport, whereas amorphous carbon is favored for coatings and composites due to its flexibility and ease of production. Understanding the differences in bonding and microstructure between graphitized and amorphous carbon is essential for optimizing material performance in energy storage, catalysis, and electronic devices.

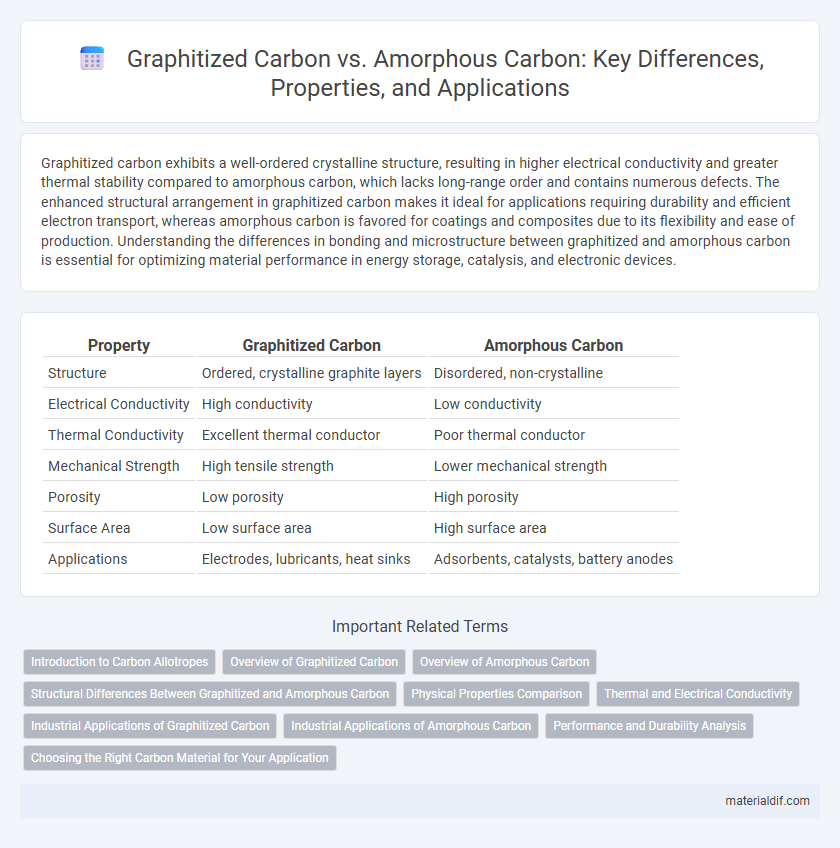

Table of Comparison

| Property | Graphitized Carbon | Amorphous Carbon |

|---|---|---|

| Structure | Ordered, crystalline graphite layers | Disordered, non-crystalline |

| Electrical Conductivity | High conductivity | Low conductivity |

| Thermal Conductivity | Excellent thermal conductor | Poor thermal conductor |

| Mechanical Strength | High tensile strength | Lower mechanical strength |

| Porosity | Low porosity | High porosity |

| Surface Area | Low surface area | High surface area |

| Applications | Electrodes, lubricants, heat sinks | Adsorbents, catalysts, battery anodes |

Introduction to Carbon Allotropes

Carbon allotropes exhibit diverse structural configurations, with graphitized carbon characterized by its ordered, planar hexagonal lattice of sp2-hybridized atoms, leading to high electrical conductivity and mechanical strength. Amorphous carbon lacks long-range order, consisting of a random network of sp2 and sp3 hybridized carbon atoms, resulting in lower density and variable electrical properties. These structural differences define their distinct applications in materials science, electronics, and catalysis.

Overview of Graphitized Carbon

Graphitized carbon consists of highly ordered layers of carbon atoms arranged in a hexagonal lattice, resulting in exceptional electrical conductivity and thermal stability. This structured arrangement distinguishes it from amorphous carbon, which lacks long-range order and exhibits lower conductivity and mechanical strength. Graphitized carbon is widely used in applications requiring high purity and durability, such as electrodes, batteries, and heat-resistant materials.

Overview of Amorphous Carbon

Amorphous carbon is a non-crystalline form of carbon characterized by a disordered atomic structure lacking long-range order, which differentiates it from graphitized carbon with its well-organized hexagonal lattice. This type of carbon exhibits a mixture of sp2 and sp3 hybridized bonds, resulting in unique physical properties such as variable electrical conductivity and enhanced chemical reactivity. Applications of amorphous carbon include use in coatings, battery electrodes, and composite materials due to its versatility and tunable surface properties.

Structural Differences Between Graphitized and Amorphous Carbon

Graphitized carbon is characterized by a well-ordered, crystalline structure with graphene layers stacked in a hexagonal lattice, resulting in high electrical conductivity and mechanical strength. In contrast, amorphous carbon lacks this long-range order, consisting of a random arrangement of carbon atoms with varying sp2 and sp3 hybridizations, leading to lower conductivity and more defects. These structural differences directly impact their applications, with graphitized carbon favored in electronics and amorphous carbon commonly used in coatings and composite materials.

Physical Properties Comparison

Graphitized carbon exhibits a highly ordered crystalline structure with hexagonal layers of carbon atoms, resulting in superior electrical conductivity, high thermal stability, and enhanced mechanical strength compared to amorphous carbon. Amorphous carbon lacks this regular structure, leading to lower density, reduced conductivity, and increased chemical reactivity. The distinct physical properties of graphitized carbon make it ideal for applications requiring durability and efficient electron transport, while amorphous carbon serves well in coatings and composite materials due to its flexibility and surface activity.

Thermal and Electrical Conductivity

Graphitized carbon exhibits significantly higher thermal conductivity, reaching up to 2000 W/m*K, and superior electrical conductivity due to its orderly crystalline structure with sp2 hybridized carbon atoms. In contrast, amorphous carbon, characterized by a disordered arrangement and mixed sp2/sp3 bonding, displays much lower thermal conductivity typically below 10 W/m*K and poor electrical conductivity. The structural differences directly influence electron mobility and phonon transport, making graphitized carbon ideal for applications requiring efficient heat dissipation and electrical conduction.

Industrial Applications of Graphitized Carbon

Graphitized carbon exhibits high electrical conductivity, thermal stability, and chemical resistance, making it ideal for industrial applications such as electrodes in batteries, fuel cells, and supercapacitors. Its ordered crystalline structure enhances durability and performance in high-temperature processes and electrochemical devices. Industries utilize graphitized carbon for manufacturing advanced composites, filtration systems, and high-strength structural materials where superior mechanical and conductive properties are essential.

Industrial Applications of Amorphous Carbon

Amorphous carbon, characterized by its disordered atomic structure, is widely utilized in industrial applications such as battery electrodes, lubricants, and coatings due to its high surface area and chemical reactivity. Its superior electrical conductivity and mechanical flexibility make it ideal for supercapacitors and flexible electronics, outperforming graphitized carbon in these roles. Industrial sectors benefit from amorphous carbon's cost-effective production processes and adaptability in composite materials, enhancing product performance and durability.

Performance and Durability Analysis

Graphitized carbon exhibits superior electrical conductivity and structural stability compared to amorphous carbon, enhancing performance in high-temperature and high-stress applications. Its ordered crystalline structure provides greater durability, resisting wear and oxidation, which prolongs component lifespan. Amorphous carbon, while offering greater surface area and flexibility, generally falls short in mechanical strength and long-term stability under harsh conditions.

Choosing the Right Carbon Material for Your Application

Graphitized carbon features a highly ordered crystalline structure, offering superior electrical conductivity and thermal stability compared to amorphous carbon, which has a disordered atomic arrangement and higher surface area. Selecting graphitized carbon is ideal for applications requiring enhanced conductivity, mechanical strength, and durability, such as electrodes and high-temperature components. Amorphous carbon is better suited for uses demanding high surface reactivity and adsorption properties, including catalysis and filtration systems.

Graphitized Carbon vs Amorphous Carbon Infographic

materialdif.com

materialdif.com