Forged carbon offers superior strength and lightweight properties due to its random fiber orientation, making it ideal for complex shapes and high-performance applications. Woven carbon, characterized by its interlaced fiber patterns, provides excellent structural integrity and consistent mechanical performance. The choice between forged and woven carbon depends on the specific design requirements, balancing flexibility, strength, and manufacturing complexity.

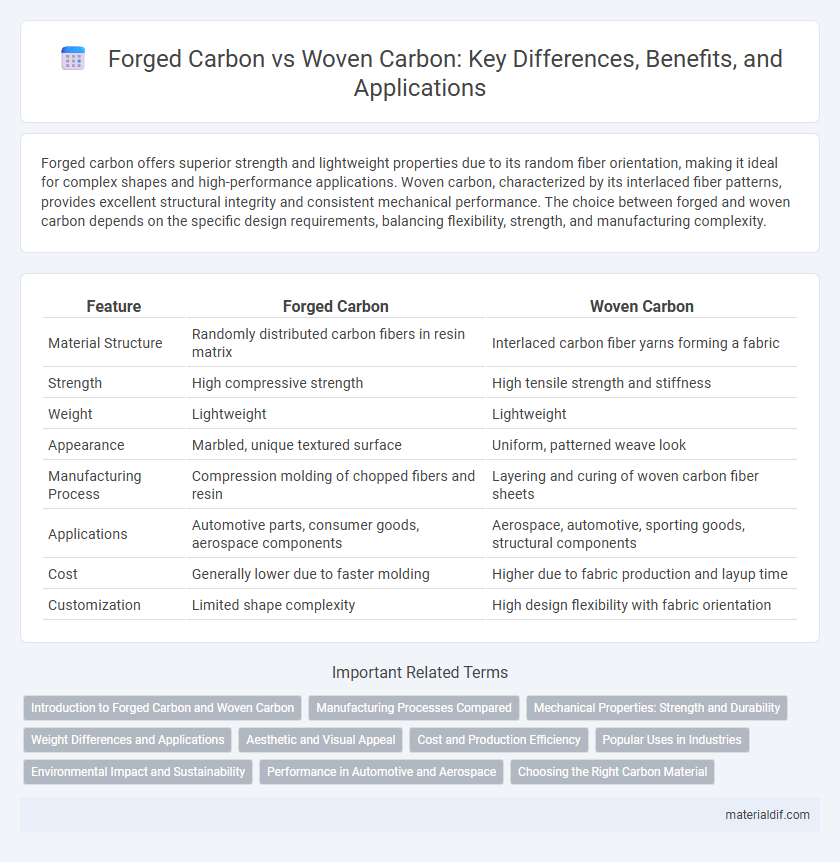

Table of Comparison

| Feature | Forged Carbon | Woven Carbon |

|---|---|---|

| Material Structure | Randomly distributed carbon fibers in resin matrix | Interlaced carbon fiber yarns forming a fabric |

| Strength | High compressive strength | High tensile strength and stiffness |

| Weight | Lightweight | Lightweight |

| Appearance | Marbled, unique textured surface | Uniform, patterned weave look |

| Manufacturing Process | Compression molding of chopped fibers and resin | Layering and curing of woven carbon fiber sheets |

| Applications | Automotive parts, consumer goods, aerospace components | Aerospace, automotive, sporting goods, structural components |

| Cost | Generally lower due to faster molding | Higher due to fabric production and layup time |

| Customization | Limited shape complexity | High design flexibility with fabric orientation |

Introduction to Forged Carbon and Woven Carbon

Forged carbon is a composite material made by compressing chopped carbon fibers mixed with resin into a mold, resulting in a dense, lightweight, and highly durable structure with a unique marbled appearance. Woven carbon, on the other hand, consists of continuous carbon fiber strands woven into fabric sheets, providing excellent strength-to-weight ratios and superior impact resistance due to the fiber orientation. Both materials are widely used in aerospace, automotive, and sports industries for their advanced mechanical properties and lightweight characteristics.

Manufacturing Processes Compared

Forged carbon involves compressing short carbon fiber composites with resin under high pressure and heat, resulting in complex shapes with high strength and lightweight properties. Woven carbon is made by layering continuous carbon fiber fabrics in specific orientations, then curing them in a mold, producing excellent mechanical strength and surface finish. Manufacturing forged carbon typically allows faster production and less waste, while woven carbon requires more labor-intensive layup and curing processes but offers superior anisotropic strength control.

Mechanical Properties: Strength and Durability

Forged carbon composites exhibit superior mechanical properties with high tensile strength and enhanced durability due to random fiber orientations, which effectively distribute stress and resist impact damage. Woven carbon fibers offer excellent strength along specific directions, providing predictable rigidity and stiffness but may be more susceptible to delamination under multi-directional loads. The choice between forged and woven carbon impacts performance outcomes in aerospace and automotive applications where balance between strength, durability, and weight is critical.

Weight Differences and Applications

Forged carbon is significantly lighter than woven carbon due to its unique manufacturing process that compresses small carbon fiber pieces with resin, resulting in a denser and more weight-efficient material ideal for high-performance automotive and aerospace components. Woven carbon consists of interlaced fibers providing superior strength and stiffness, making it better suited for applications requiring structural integrity such as sporting goods and protective gear. The choice between forged and woven carbon balances weight savings versus mechanical properties, influencing design decisions across industries from racing cars to aerospace engineering.

Aesthetic and Visual Appeal

Forged carbon features a unique, marbled pattern that delivers a distinct, high-tech aesthetic with irregular, randomized textures, enhancing visual complexity and modern appeal. Woven carbon displays a uniform, grid-like weave pattern that emphasizes precision, symmetry, and a classic, sophisticated look favored in luxury and performance applications. Both materials offer striking visual effects, with forged carbon appealing to those seeking innovation and individuality, while woven carbon attracts enthusiasts of traditional craftsmanship and sleek design.

Cost and Production Efficiency

Forged carbon offers significant cost advantages due to its rapid production process, which involves compressing carbon fiber chunks with resin in a mold, reducing labor and material waste compared to woven carbon. Woven carbon requires a more time-consuming weaving process that increases production complexity and costs, especially for intricate designs. Forged carbon's ability to be molded into complex shapes quickly makes it a more efficient and cost-effective option for high-volume manufacturing.

Popular Uses in Industries

Forged carbon is widely used in automotive and aerospace industries for high-performance components due to its superior strength-to-weight ratio and complex shape adaptability. Woven carbon is favored in sporting goods and consumer electronics, offering enhanced fatigue resistance and aesthetic appeal through its distinct fabric texture. Both materials are integral in manufacturing lightweight, durable products but serve different structural and design requirements across various industrial applications.

Environmental Impact and Sustainability

Forged carbon features randomly chopped fibers bonded with resin, resulting in less material waste and faster production compared to woven carbon, which uses continuous fibers woven into fabric. Woven carbon offers superior strength-to-weight ratios but involves more energy-intensive manufacturing processes that impact its overall environmental footprint. Choosing forged carbon can reduce carbon emissions and resource consumption, promoting greater sustainability in high-performance applications.

Performance in Automotive and Aerospace

Forged carbon offers superior impact resistance and isotropic strength due to its random fiber orientation, making it ideal for high-performance automotive and aerospace components exposed to complex stress patterns. Woven carbon provides excellent tensile strength and stiffness along specific fiber directions, benefiting structural parts that require predictable load-bearing capabilities. Optimizing between forged and woven carbon materials enhances both durability and weight reduction in advanced vehicle and aircraft design.

Choosing the Right Carbon Material

Forged carbon offers superior strength-to-weight ratios and enhanced impact resistance, making it ideal for high-performance applications requiring durability and lightweight properties. Woven carbon provides excellent tensile strength and aesthetic appeal, favored in designs where flexibility and a refined finish are priorities. Selecting between forged and woven carbon hinges on balancing structural demands with visual and tactile requirements in carbon fiber manufacturing.

Forged carbon vs Woven carbon Infographic

materialdif.com

materialdif.com