Carbon cloth offers enhanced flexibility and breathability, making it ideal for applications requiring lightweight reinforcement with complex shapes. Carbon tape provides superior directional strength and consistency, perfect for precise lamination and structural repairs. Choosing between carbon cloth and carbon tape depends on the specific mechanical performance and molding requirements of the project.

Table of Comparison

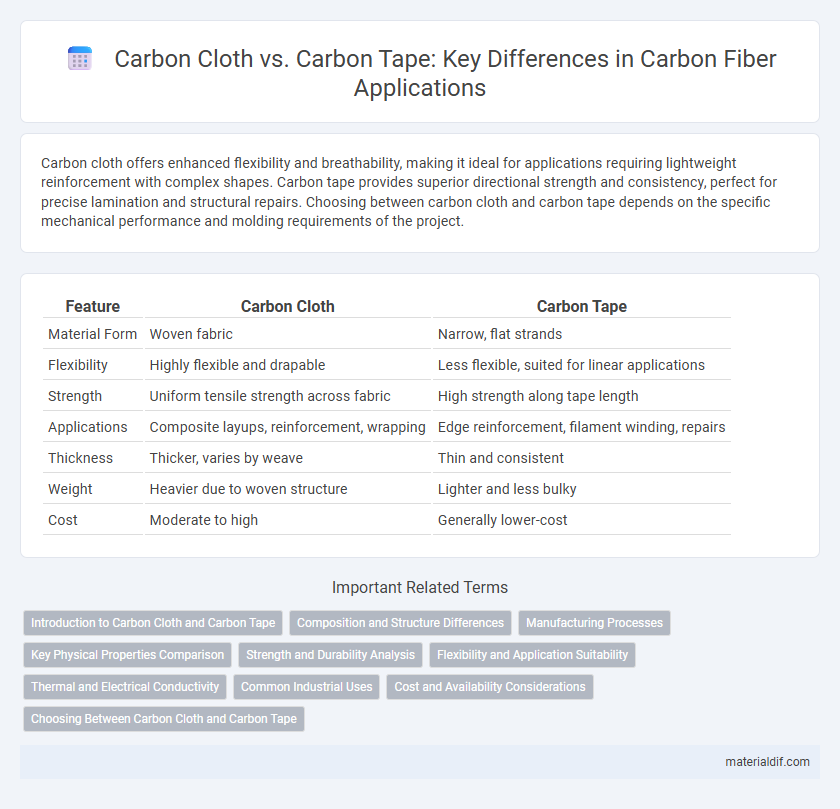

| Feature | Carbon Cloth | Carbon Tape |

|---|---|---|

| Material Form | Woven fabric | Narrow, flat strands |

| Flexibility | Highly flexible and drapable | Less flexible, suited for linear applications |

| Strength | Uniform tensile strength across fabric | High strength along tape length |

| Applications | Composite layups, reinforcement, wrapping | Edge reinforcement, filament winding, repairs |

| Thickness | Thicker, varies by weave | Thin and consistent |

| Weight | Heavier due to woven structure | Lighter and less bulky |

| Cost | Moderate to high | Generally lower-cost |

Introduction to Carbon Cloth and Carbon Tape

Carbon cloth consists of woven carbon fibers forming a flexible textile, widely used in aerospace and automotive applications for its high tensile strength and thermal stability. Carbon tape, by contrast, is a unidirectional reinforcement material made from aligned carbon fibers, offering superior stiffness and strength in one direction, ideal for composite layups requiring precise fiber orientation. Both materials significantly enhance structural performance and weight reduction in advanced engineering designs.

Composition and Structure Differences

Carbon cloth consists of woven carbon fibers forming a fabric with high tensile strength and flexibility, ideal for composite reinforcements. Carbon tape, by contrast, is made of unidirectional carbon fibers aligned in parallel bundles, offering superior stiffness and directional strength. The distinct weaving pattern of carbon cloth versus the linear fiber arrangement in carbon tape results in varied mechanical properties suited to different engineering applications.

Manufacturing Processes

Carbon cloth is manufactured through weaving carbon fibers into a flexible fabric, enabling enhanced durability and moldability for composite applications. Carbon tape involves aligning unidirectional carbon fibers and binding them with resin, producing a thin, stiff material optimized for strength in linear load directions. The choice between cloth and tape manufacturing impacts mechanical properties, layup complexity, and suitability for specific aerospace, automotive, or sporting goods applications.

Key Physical Properties Comparison

Carbon cloth offers superior flexibility and drapability, making it ideal for complex shapes and conforms easily to curved surfaces. Carbon tape, characterized by its uniform width and thickness, provides higher tensile strength and is preferred for applications requiring precise reinforcement and load distribution. The enhanced mechanical properties of carbon tape, combined with the adaptability of carbon cloth, determine their specific use in aerospace, automotive, and sporting goods manufacturing.

Strength and Durability Analysis

Carbon cloth demonstrates superior strength uniformity and exceptional durability due to its woven fiber architecture, which evenly distributes stress and resists fatigue. Carbon tape, featuring unidirectional fibers, excels in tensile strength along the fiber direction but shows limited durability against multi-directional forces and impact. In applications requiring consistent load resistance and long-term structural integrity, carbon cloth is often preferred over carbon tape.

Flexibility and Application Suitability

Carbon cloth offers superior flexibility due to its woven fiber structure, making it ideal for complex contoured surfaces and dynamic applications such as aerospace and automotive components. Carbon tape, characterized by its unidirectional fibers, provides higher stiffness and strength but limited flexibility, suitable for applications requiring precise load paths like structural reinforcements in composites and sporting goods. Selecting between carbon cloth and tape depends on the balance between needed flexibility and mechanical performance for the target application.

Thermal and Electrical Conductivity

Carbon cloth exhibits superior thermal conductivity compared to carbon tape due to its woven fiber structure that facilitates efficient heat dissipation across surfaces. In terms of electrical conductivity, carbon cloth typically provides more uniform current distribution because of its continuous fiber network, whereas carbon tape, composed of aligned but discrete fibers, offers higher directional electrical conductivity along the fiber orientation. These properties make carbon cloth ideal for applications requiring multidirectional thermal management and consistent conductivity, while carbon tape is preferred for targeted electrical conduction in composite manufacturing.

Common Industrial Uses

Carbon cloth offers a flexible, woven fabric ideal for manufacturing lightweight, high-strength components in aerospace, automotive, and sporting goods industries. Carbon tape, with its unidirectional fiber alignment, provides superior tensile strength for reinforcing structures in wind turbine blades, pressure vessels, and composite repair applications. Both materials are essential in industrial settings for enhancing durability, stiffness, and corrosion resistance of advanced composite products.

Cost and Availability Considerations

Carbon cloth tends to be more expensive than carbon tape due to its complex weaving process and higher material consumption, impacting the overall project budget. Availability of carbon cloth is generally broader, as it is widely used in various industries such as aerospace, automotive, and sports equipment, while carbon tape availability may be more limited to niche applications like localized reinforcements. Choosing between carbon cloth and carbon tape depends on cost constraints and the need for material supply consistency in production timelines.

Choosing Between Carbon Cloth and Carbon Tape

Choosing between carbon cloth and carbon tape depends on the application's flexibility and strength requirements. Carbon cloth offers superior conformability and is ideal for complex shapes, while carbon tape provides higher tensile strength and is better suited for linear reinforcement and repair. Understanding the mechanical properties and bonding characteristics of each material ensures optimal performance in composite manufacturing.

Carbon Cloth vs Carbon Tape Infographic

materialdif.com

materialdif.com