Surface-treated carbon fiber exhibits enhanced adhesion properties and improved durability compared to untreated carbon fiber, making it ideal for composite applications that require strong bonding with resins. The treatment process modifies the fiber surface to increase wettability and compatibility with various matrix materials, resulting in superior mechanical performance and resistance to environmental degradation. Untreated carbon fiber, while lightweight and strong, often suffers from poor interfacial bonding, limiting its effectiveness in high-stress or demanding applications.

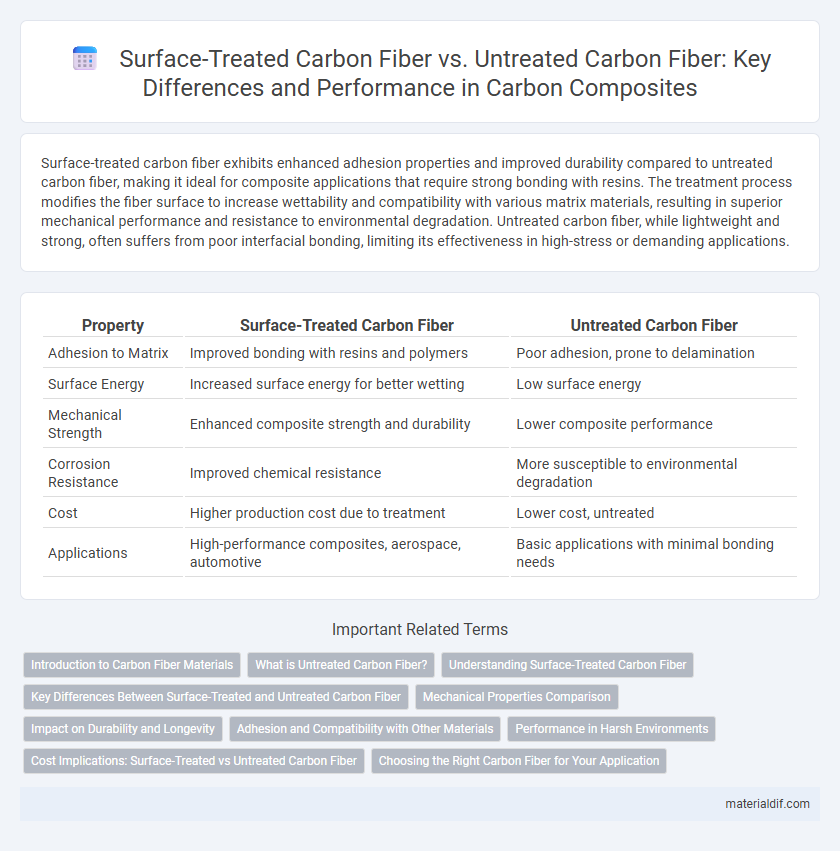

Table of Comparison

| Property | Surface-Treated Carbon Fiber | Untreated Carbon Fiber |

|---|---|---|

| Adhesion to Matrix | Improved bonding with resins and polymers | Poor adhesion, prone to delamination |

| Surface Energy | Increased surface energy for better wetting | Low surface energy |

| Mechanical Strength | Enhanced composite strength and durability | Lower composite performance |

| Corrosion Resistance | Improved chemical resistance | More susceptible to environmental degradation |

| Cost | Higher production cost due to treatment | Lower cost, untreated |

| Applications | High-performance composites, aerospace, automotive | Basic applications with minimal bonding needs |

Introduction to Carbon Fiber Materials

Surface-treated carbon fiber exhibits enhanced adhesion properties and improved bonding with resins compared to untreated carbon fiber, resulting in superior composite material strength and durability. Untreated carbon fiber lacks surface modifications, which can lead to weaker interfacial bonding and reduced mechanical performance in composite applications. The surface treatment process typically involves oxidative or plasma treatments that increase surface energy and activate chemical functional groups, crucial for high-performance carbon fiber composites in aerospace, automotive, and sports equipment industries.

What is Untreated Carbon Fiber?

Untreated carbon fiber consists of raw carbon filaments without any surface modifications or coatings, which results in low chemical reactivity and poor bonding with matrix materials in composites. Its smooth surface hinders adhesion, leading to weaker mechanical properties when integrated into polymers or resins. Surface treatments like plasma etching, oxidation, or sizing improve fiber-matrix bonding by increasing surface energy and introducing functional groups, enhancing composite strength and durability.

Understanding Surface-Treated Carbon Fiber

Surface-treated carbon fiber features a specialized coating that enhances its bonding properties with composite materials, improving mechanical strength and durability. The treatment process modifies the fiber surface chemistry, promoting better adhesion with resins and reducing the risk of delamination in finished products. Compared to untreated carbon fiber, surface-treated variants provide superior performance in aerospace, automotive, and sporting goods applications where structural integrity is critical.

Key Differences Between Surface-Treated and Untreated Carbon Fiber

Surface-treated carbon fiber exhibits enhanced adhesion properties and improved compatibility with polymer matrices due to chemical or physical modifications on its surface, whereas untreated carbon fiber maintains its original smooth, inert surface. The surface treatment increases interfacial bonding strength, resulting in composites with superior mechanical performance and durability compared to those made with untreated fibers. Untreated carbon fiber often suffers from poor matrix adhesion, leading to weaker composites and reduced structural integrity.

Mechanical Properties Comparison

Surface-treated carbon fiber exhibits significantly enhanced mechanical properties compared to untreated carbon fiber, including improved tensile strength and interfacial bonding with resin matrices. The surface treatment modifies the fiber's chemical composition, promoting better adhesion and load transfer within composite materials. Untreated carbon fiber often shows lower mechanical performance due to weak fiber-matrix interaction and higher susceptibility to fiber pull-out under stress.

Impact on Durability and Longevity

Surface-treated carbon fiber exhibits significantly enhanced durability and longevity due to improved adhesion between fibers and matrix materials, reducing the risk of delamination and fiber pull-out. Untreated carbon fiber lacks this improved interfacial bonding, leading to higher susceptibility to mechanical wear, moisture ingress, and environmental degradation. The surface treatment process, often involving oxidation or plasma treatments, creates functional groups that promote stronger chemical bonds, thereby extending the service life of carbon fiber composites.

Adhesion and Compatibility with Other Materials

Surface-treated carbon fiber exhibits enhanced adhesion properties and improved compatibility with resin matrices, resulting from chemical or plasma treatments that increase surface energy and roughness. Untreated carbon fiber has lower surface energy, leading to poor bonding with epoxy or thermoplastic polymers and reduced mechanical performance in composites. The improved interfacial bonding of surface-treated fibers significantly enhances load transfer and durability in high-performance composite applications.

Performance in Harsh Environments

Surface-treated carbon fiber exhibits superior resistance to corrosion, UV degradation, and moisture infiltration compared to untreated carbon fiber, ensuring enhanced durability and mechanical integrity in harsh environments. The chemical treatments form a protective barrier that minimizes matrix debonding and fiber degradation under extreme temperature fluctuations and chemical exposure. Untreated carbon fiber lacks this protective coating, making it prone to surface damage and reduced lifespan when subjected to aggressive environmental conditions.

Cost Implications: Surface-Treated vs Untreated Carbon Fiber

Surface-treated carbon fiber incurs higher production costs due to additional chemical or plasma treatments that enhance fiber-matrix adhesion and mechanical properties. Untreated carbon fiber remains more affordable but may result in compromised composite performance, potentially leading to increased maintenance or replacement expenses. The cost-benefit analysis depends on application-specific requirements for strength, durability, and longevity.

Choosing the Right Carbon Fiber for Your Application

Surface-treated carbon fiber offers enhanced adhesion and improved durability by chemically modifying the fiber's surface, making it ideal for composite materials requiring strong bonding with resins. Untreated carbon fiber, while retaining its raw strength and lightweight properties, may exhibit weaker matrix adhesion and is better suited for applications where surface bonding is less critical. Selecting the right carbon fiber depends on specific application demands, such as mechanical performance, environmental exposure, and compatibility with other materials in the composite structure.

Surface-treated carbon fiber vs Untreated carbon fiber Infographic

materialdif.com

materialdif.com