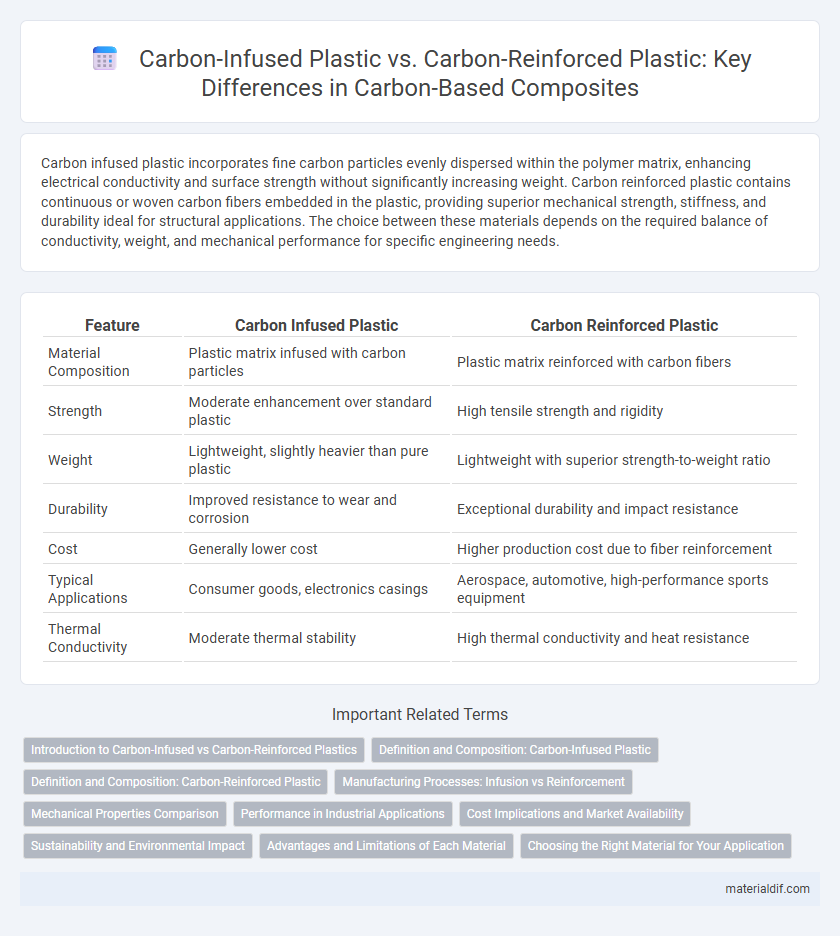

Carbon infused plastic incorporates fine carbon particles evenly dispersed within the polymer matrix, enhancing electrical conductivity and surface strength without significantly increasing weight. Carbon reinforced plastic contains continuous or woven carbon fibers embedded in the plastic, providing superior mechanical strength, stiffness, and durability ideal for structural applications. The choice between these materials depends on the required balance of conductivity, weight, and mechanical performance for specific engineering needs.

Table of Comparison

| Feature | Carbon Infused Plastic | Carbon Reinforced Plastic |

|---|---|---|

| Material Composition | Plastic matrix infused with carbon particles | Plastic matrix reinforced with carbon fibers |

| Strength | Moderate enhancement over standard plastic | High tensile strength and rigidity |

| Weight | Lightweight, slightly heavier than pure plastic | Lightweight with superior strength-to-weight ratio |

| Durability | Improved resistance to wear and corrosion | Exceptional durability and impact resistance |

| Cost | Generally lower cost | Higher production cost due to fiber reinforcement |

| Typical Applications | Consumer goods, electronics casings | Aerospace, automotive, high-performance sports equipment |

| Thermal Conductivity | Moderate thermal stability | High thermal conductivity and heat resistance |

Introduction to Carbon-Infused vs Carbon-Reinforced Plastics

Carbon-infused plastics incorporate fine carbon particles dispersed throughout the polymer matrix, enhancing electrical conductivity and thermal stability while maintaining lightweight properties. Carbon-reinforced plastics embed continuous carbon fibers within the polymer, significantly improving tensile strength and structural rigidity for high-performance engineering applications. Understanding the differences in morphology and mechanical attributes helps optimize material selection for aerospace, automotive, and sporting goods industries.

Definition and Composition: Carbon-Infused Plastic

Carbon-infused plastic, also known as carbon-filled plastic, is a composite material where carbon fibers or carbon powder are blended directly into the plastic matrix to enhance its mechanical properties and conductivity. Unlike carbon-reinforced plastic, which typically contains continuous or woven carbon fiber layers, carbon-infused plastic incorporates short or chopped carbon fibers uniformly distributed throughout the polymer, resulting in improved stiffness, thermal stability, and electrical conductivity without significantly altering the plastic's moldability. The plastic matrix commonly consists of thermoplastics or thermosets such as polypropylene or epoxy resin, optimized to maintain a balance between lightweight characteristics and enhanced performance.

Definition and Composition: Carbon-Reinforced Plastic

Carbon-reinforced plastic (CRP) is a composite material composed of carbon fibers embedded in a polymer matrix, typically epoxy or thermoplastic resin, providing enhanced strength and stiffness. Unlike carbon-infused plastic, where carbon particles are dispersed within the plastic to improve properties, CRP utilizes continuous or woven carbon fiber fabrics to achieve superior mechanical performance. The arrangement and orientation of carbon fibers within the matrix significantly influence the material's load-bearing capabilities and structural integrity in aerospace, automotive, and sporting goods applications.

Manufacturing Processes: Infusion vs Reinforcement

Carbon infused plastic involves embedding carbon nanotubes or fibers into the polymer matrix during the melting or mixing stage, enhancing electrical conductivity and mechanical properties uniformly throughout the material. Carbon reinforced plastic manufacturing uses layering techniques where carbon fiber sheets are impregnated with resin and then cured, resulting in high strength-to-weight ratios ideal for structural applications. The infusion process allows for mass production with improved material homogeneity, while reinforcement requires precise lamination and curing for tailored mechanical performance.

Mechanical Properties Comparison

Carbon infused plastic exhibits enhanced stiffness and moderate tensile strength due to the uniform dispersion of carbon particles within the polymer matrix, improving impact resistance and wear properties. Carbon reinforced plastic, typically composed of carbon fiber layers embedded in a resin, offers superior tensile strength, higher modulus, and exceptional fatigue resistance, making it ideal for structural and load-bearing applications. The mechanical performance gap is significant, with carbon reinforced plastics providing better strength-to-weight ratios and durability under cyclic loading compared to carbon infused plastics.

Performance in Industrial Applications

Carbon infused plastic offers enhanced thermal conductivity and electrical properties, making it suitable for applications requiring lightweight components with moderate strength. Carbon reinforced plastic (CRP) surpasses in tensile strength and stiffness due to continuous carbon fibers embedded within the polymer matrix, providing superior performance in load-bearing industrial parts. CRP's high strength-to-weight ratio and durability make it ideal for aerospace, automotive, and structural applications demanding extreme mechanical performance.

Cost Implications and Market Availability

Carbon infused plastic generally offers a lower production cost compared to carbon reinforced plastic due to its simpler manufacturing processes and lower carbon fiber content. Carbon reinforced plastic, known for superior strength and stiffness, commands higher prices and targets specialized markets such as aerospace and automotive sectors. Market availability of carbon infused plastic is broader and growing in consumer goods, while carbon reinforced plastic remains niche with limited suppliers focused on high-performance applications.

Sustainability and Environmental Impact

Carbon infused plastic integrates carbon particles into the polymer matrix, enhancing strength with minimal material increase, leading to lower carbon footprints due to reduced resource consumption. Carbon reinforced plastic utilizes continuous carbon fibers, offering superior mechanical performance but requiring energy-intensive manufacturing processes and challenges in recycling, impacting sustainability negatively. Lifecycle assessments reveal that carbon infused plastics achieve better environmental profiles through easier recyclability and lower energy inputs compared to carbon reinforced composites.

Advantages and Limitations of Each Material

Carbon infused plastic offers enhanced electrical conductivity and improved thermal management, making it suitable for electronic housings and lightweight components. However, its mechanical strength and stiffness are lower compared to carbon reinforced plastic, limiting its use in high-load structural applications. Carbon reinforced plastic provides superior tensile strength, stiffness, and impact resistance, ideal for aerospace and automotive parts, but it generally incurs higher production costs and complex manufacturing processes.

Choosing the Right Material for Your Application

Carbon infused plastic offers enhanced electrical conductivity and improved thermal management, making it ideal for electronic housings and heat dissipation components. Carbon reinforced plastic provides superior mechanical strength and stiffness, suited for aerospace, automotive, and structural applications demanding high durability. Selecting between these materials depends on whether electrical performance or mechanical robustness is prioritized in the specific application.

Carbon infused plastic vs Carbon reinforced plastic Infographic

materialdif.com

materialdif.com