Carbon composites offer enhanced mechanical strength and lightweight properties by combining carbon fibers with resin matrices, widely used in aerospace and automotive industries. Carbon nanotubes exhibit exceptional electrical conductivity and tensile strength on a nanoscale, making them ideal for advanced electronics, sensors, and nanotechnology applications. The integration of carbon nanotubes into carbon composites results in hybrid materials with superior performance in terms of durability, flexibility, and multifunctionality.

Table of Comparison

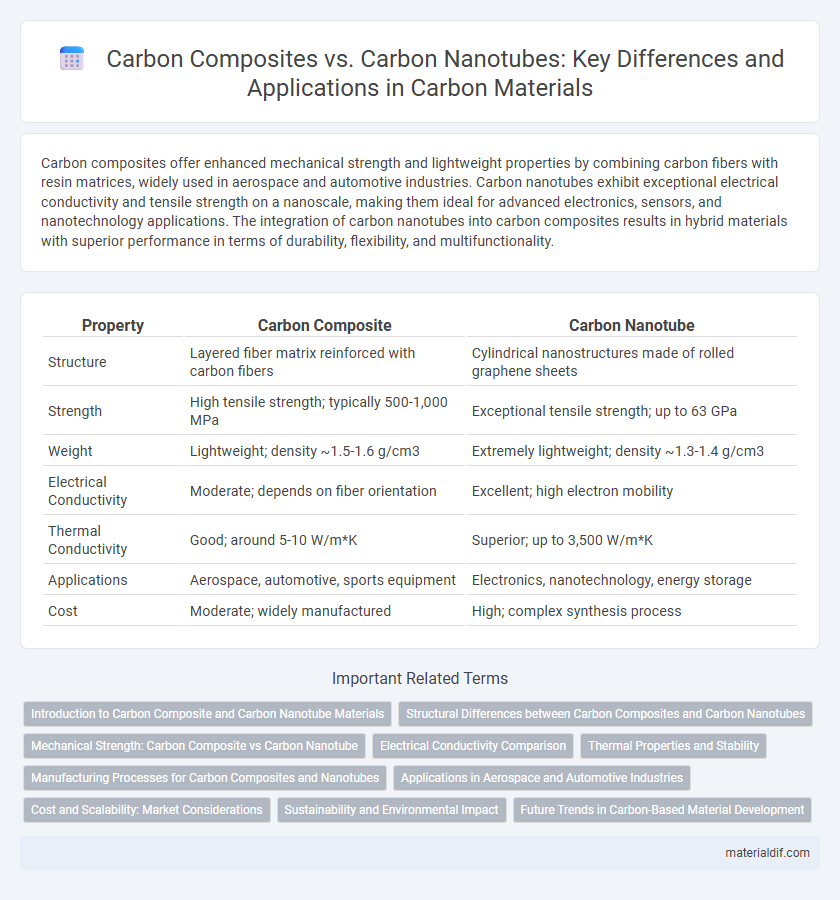

| Property | Carbon Composite | Carbon Nanotube |

|---|---|---|

| Structure | Layered fiber matrix reinforced with carbon fibers | Cylindrical nanostructures made of rolled graphene sheets |

| Strength | High tensile strength; typically 500-1,000 MPa | Exceptional tensile strength; up to 63 GPa |

| Weight | Lightweight; density ~1.5-1.6 g/cm3 | Extremely lightweight; density ~1.3-1.4 g/cm3 |

| Electrical Conductivity | Moderate; depends on fiber orientation | Excellent; high electron mobility |

| Thermal Conductivity | Good; around 5-10 W/m*K | Superior; up to 3,500 W/m*K |

| Applications | Aerospace, automotive, sports equipment | Electronics, nanotechnology, energy storage |

| Cost | Moderate; widely manufactured | High; complex synthesis process |

Introduction to Carbon Composite and Carbon Nanotube Materials

Carbon composites combine carbon fibers with polymer, metal, or ceramic matrices to create lightweight, high-strength materials widely used in aerospace, automotive, and sports equipment industries. Carbon nanotubes (CNTs) are cylindrical nanostructures with exceptional tensile strength, electrical conductivity, and thermal properties, offering advanced capabilities in nanotechnology and materials science. While carbon composites emphasize macroscopic reinforcement, carbon nanotubes enable molecular-level enhancements, making both essential for innovative material design and engineering applications.

Structural Differences between Carbon Composites and Carbon Nanotubes

Carbon composites consist of carbon fibers embedded in a polymer matrix, providing high strength and lightweight properties through macroscopic fiber reinforcement. Carbon nanotubes are cylindrical nanostructures formed by rolled graphene sheets with remarkable tensile strength and elasticity at the atomic scale. Structural differences include the scale of reinforcement, with composites operating on fiber bundles and nanotubes featuring atomic-scale carbon atom arrangements.

Mechanical Strength: Carbon Composite vs Carbon Nanotube

Carbon composites exhibit high mechanical strength through the integration of carbon fibers within a polymer matrix, offering excellent tensile strength and stiffness for structural applications. Carbon nanotubes demonstrate superior mechanical properties on the nanoscale, featuring exceptional tensile strength up to 100 times greater than steel and remarkable elasticity. The nanoscale reinforcement potential of carbon nanotubes outperforms traditional carbon composites, enabling advanced material designs with enhanced durability and lightweight performance.

Electrical Conductivity Comparison

Carbon nanotubes exhibit significantly higher electrical conductivity compared to traditional carbon composites due to their exceptional electron mobility and one-dimensional structure. While carbon composites rely on the conductivity of carbon fibers embedded in a matrix, carbon nanotubes provide superior conductive pathways through their nanoscale dimensions and intrinsic metallic or semiconducting properties. This enhanced electrical conductivity positions carbon nanotubes as a leading material for advanced electronic, energy storage, and sensing applications.

Thermal Properties and Stability

Carbon composites exhibit excellent thermal stability and can withstand temperatures up to 600degC while maintaining structural integrity, making them ideal for aerospace and automotive applications. Carbon nanotubes (CNTs) offer superior thermal conductivity, ranging from 2000 to 3000 W/m*K, significantly outperforming traditional carbon composites that typically have conductivities below 50 W/m*K. The exceptional thermal properties of CNTs, combined with their chemical stability at high temperatures, enable their use in advanced heat dissipation systems and thermal management technologies.

Manufacturing Processes for Carbon Composites and Nanotubes

Carbon composites are manufactured through layering carbon fibers with resin matrices using processes such as filament winding, resin transfer molding, and autoclave curing, ensuring high strength-to-weight ratios. Carbon nanotubes are synthesized primarily via chemical vapor deposition (CVD), arc discharge, or laser ablation, allowing control over nanotube structure and purity at the nanoscale. Advanced manufacturing techniques for carbon nanotubes focus on achieving uniformity and scalability for integration into composite materials and electronic devices.

Applications in Aerospace and Automotive Industries

Carbon composites, known for their high strength-to-weight ratio and corrosion resistance, are widely used in aerospace and automotive industries for structural components, such as aircraft fuselages and automotive body panels, enhancing fuel efficiency and performance. Carbon nanotubes offer exceptional mechanical, electrical, and thermal properties, enabling their use in lightweight, high-strength composites and conductive materials, improving energy storage and durability in aerospace and electric vehicle applications. Integration of carbon nanotube-enhanced composites drives innovation in lightweight materials, advancing next-generation design and sustainability in both sectors.

Cost and Scalability: Market Considerations

Carbon composites offer comparatively lower production costs and established scalability due to mature manufacturing processes, making them favorable for large-scale industrial applications. Carbon nanotubes, while exhibiting superior mechanical and electrical properties, face higher costs and production challenges that limit their current market scalability. Investments in scalable synthesis techniques for carbon nanotubes are crucial to achieving competitive pricing and broader commercial adoption.

Sustainability and Environmental Impact

Carbon composites offer enhanced sustainability through their lightweight structure, reducing fuel consumption in transportation and lowering carbon emissions over product lifecycles. Carbon nanotubes provide significant environmental benefits by enabling stronger, more durable materials that extend product life and reduce resource depletion in manufacturing. Both materials contribute to eco-friendly innovations but carbon nanotubes, due to their nanoscale properties, present greater potential for reducing environmental impact via improved energy efficiency and recyclability.

Future Trends in Carbon-Based Material Development

Advancements in carbon composite materials emphasize enhanced strength-to-weight ratios and cost-effective manufacturing techniques, driving widespread adoption in aerospace and automotive industries. Carbon nanotube research focuses on exploiting exceptional electrical conductivity and mechanical properties to develop next-generation electronics, energy storage, and nanodevices. Future trends indicate a convergence of carbon composites and nanotube technologies, fostering hybrid materials with multifunctional capabilities and sustainable performance improvements.

Carbon composite vs Carbon nanotube Infographic

materialdif.com

materialdif.com