Prepreg carbon offers superior strength and consistency due to its pre-impregnated resin system, ensuring precise fiber-to-resin ratios and reduced void content. Wet layup carbon, while more cost-effective and flexible for complex shapes, often results in lower mechanical properties and higher weight because of manual resin application. The choice between prepreg and wet layup carbon depends on performance requirements, budget constraints, and production scale.

Table of Comparison

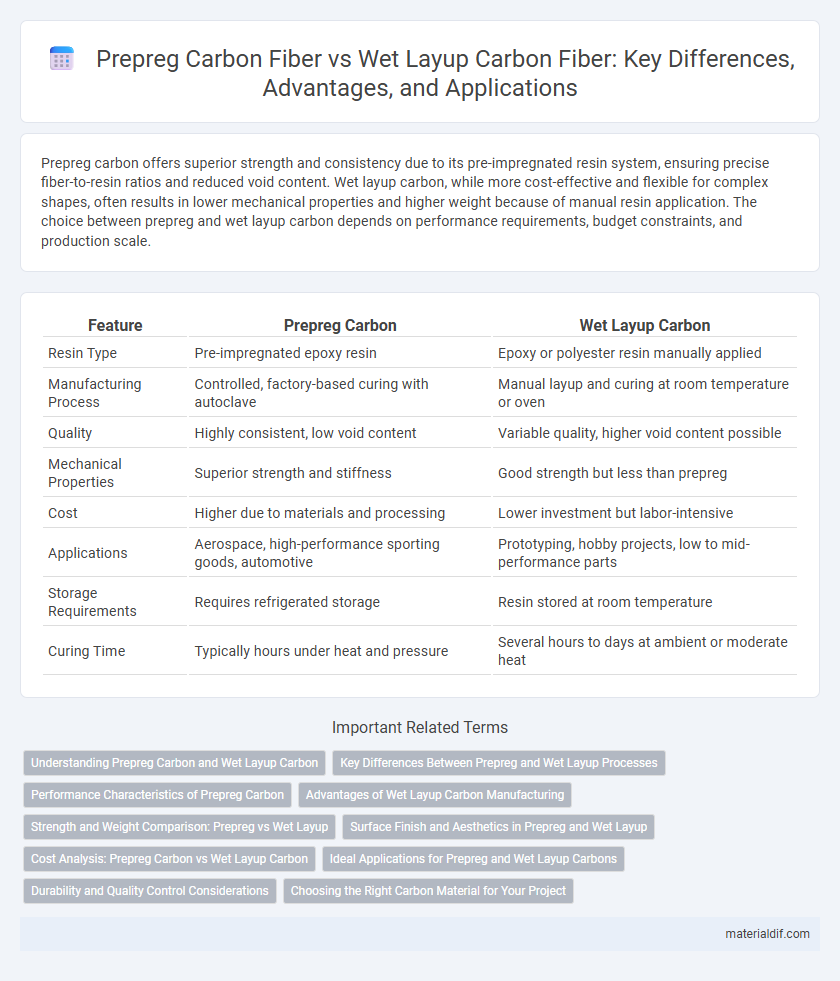

| Feature | Prepreg Carbon | Wet Layup Carbon |

|---|---|---|

| Resin Type | Pre-impregnated epoxy resin | Epoxy or polyester resin manually applied |

| Manufacturing Process | Controlled, factory-based curing with autoclave | Manual layup and curing at room temperature or oven |

| Quality | Highly consistent, low void content | Variable quality, higher void content possible |

| Mechanical Properties | Superior strength and stiffness | Good strength but less than prepreg |

| Cost | Higher due to materials and processing | Lower investment but labor-intensive |

| Applications | Aerospace, high-performance sporting goods, automotive | Prototyping, hobby projects, low to mid-performance parts |

| Storage Requirements | Requires refrigerated storage | Resin stored at room temperature |

| Curing Time | Typically hours under heat and pressure | Several hours to days at ambient or moderate heat |

Understanding Prepreg Carbon and Wet Layup Carbon

Prepreg carbon fibers are pre-impregnated with a controlled amount of resin, offering superior consistency, strength, and finished product quality compared to wet layup carbon, which involves manually applying resin onto dry carbon fabric. Prepreg carbon requires refrigeration storage and precise curing processes, typically in an autoclave, to achieve optimal mechanical properties and a higher fiber-to-resin ratio. Wet layup carbon is more cost-effective and flexible for smaller projects but generally results in heavier, less durable composites with variable resin distribution.

Key Differences Between Prepreg and Wet Layup Processes

Prepreg carbon utilizes pre-impregnated fibers with a precise resin-to-fiber ratio, ensuring superior consistency and mechanical properties compared to wet layup carbon, where resin is manually applied to dry fibers. Prepreg processes require controlled curing environments like autoclaves or ovens, resulting in higher strength-to-weight ratios and reduced void content, whereas wet layup offers more flexibility and lower initial costs but with potential variability in resin distribution. The choice impacts performance, manufacturing complexity, and cost efficiency in applications such as aerospace, automotive, and sporting goods.

Performance Characteristics of Prepreg Carbon

Prepreg carbon offers superior mechanical properties, including higher tensile strength and improved stiffness, due to its uniform resin distribution and controlled fiber alignment during manufacturing. This results in enhanced fatigue resistance and dimensional stability compared to wet layup carbon composites, which often suffer from inconsistent resin content and potential voids. The precision curing process in prepreg carbon also enables better repeatability and optimized weight-to-strength ratios, crucial for high-performance aerospace and automotive applications.

Advantages of Wet Layup Carbon Manufacturing

Wet layup carbon manufacturing offers greater design flexibility and cost-effectiveness compared to prepreg carbon, making it ideal for low-volume or custom applications. The process allows for easy adjustment of resin content and laminate thickness, which enhances material performance and structural integrity tailored to specific requirements. Additionally, wet layup equipment is more accessible and requires less specialized storage, reducing overall production complexity and expense.

Strength and Weight Comparison: Prepreg vs Wet Layup

Prepreg carbon fiber offers higher strength-to-weight ratios compared to wet layup carbon due to its controlled resin content and superior fiber alignment. This precision manufacturing results in lighter components with enhanced mechanical properties, ideal for aerospace and high-performance automotive applications. Wet layup carbon, while more cost-effective and versatile for complex shapes, tends to have higher resin content, making it heavier and less strong than prepreg alternatives.

Surface Finish and Aesthetics in Prepreg and Wet Layup

Prepreg carbon offers superior surface finish and aesthetics due to its precise resin-to-fiber ratio and controlled curing process, resulting in a smooth, glossy, and uniform appearance. Wet layup carbon often exhibits a less consistent surface with visible resin pooling and air bubbles, leading to a rougher texture and less appealing visual quality. High-end automotive and aerospace applications favor prepreg for its enhanced cosmetic appeal and flawless contours.

Cost Analysis: Prepreg Carbon vs Wet Layup Carbon

Prepreg carbon offers higher material costs compared to wet layup carbon due to its pre-impregnated fibers requiring specialized storage and handling, increasing overall expenses. Wet layup carbon remains more cost-effective with lower raw material costs and simpler processing methods, making it suitable for budget-sensitive projects. However, prepreg carbon's improved consistency and reduced labor time can offset initial costs by enhancing production efficiency and part quality.

Ideal Applications for Prepreg and Wet Layup Carbons

Prepreg carbon is ideal for high-performance aerospace, motorsports, and automotive applications requiring precise fiber alignment, superior strength-to-weight ratios, and consistent resin distribution, enabling enhanced mechanical properties and excellent surface finishes. Wet layup carbon suits lower-budget projects, prototyping, marine, and hobbyist uses where flexibility in resin choice and simpler processing outweigh the need for stringent quality control or maximum structural integrity. Selecting prepreg or wet layup methods depends on factors like production scale, performance demands, environmental exposure, and available curing equipment.

Durability and Quality Control Considerations

Prepreg carbon offers superior durability due to its precise resin-to-fiber ratio and controlled curing process, resulting in consistent mechanical properties and reduced void content. Quality control is enhanced through factory-prepared prepregs that minimize human error and environmental variability compared to wet layup carbon, which relies on manual resin application and is prone to inconsistencies and higher porosity. The controlled autoclave curing of prepreg carbon ensures enhanced interlaminar strength and fatigue resistance, critical for high-performance applications.

Choosing the Right Carbon Material for Your Project

Prepreg carbon offers superior strength-to-weight ratio and enhanced resin control due to its pre-impregnated fiber sheets, making it ideal for high-performance applications requiring precision and durability. Wet layup carbon is more cost-effective and flexible for small-scale or custom projects where tooling and equipment limitations exist. Selecting between prepreg and wet layup carbon depends on project budget, performance requirements, and available manufacturing resources.

Prepreg carbon vs Wet layup carbon Infographic

materialdif.com

materialdif.com