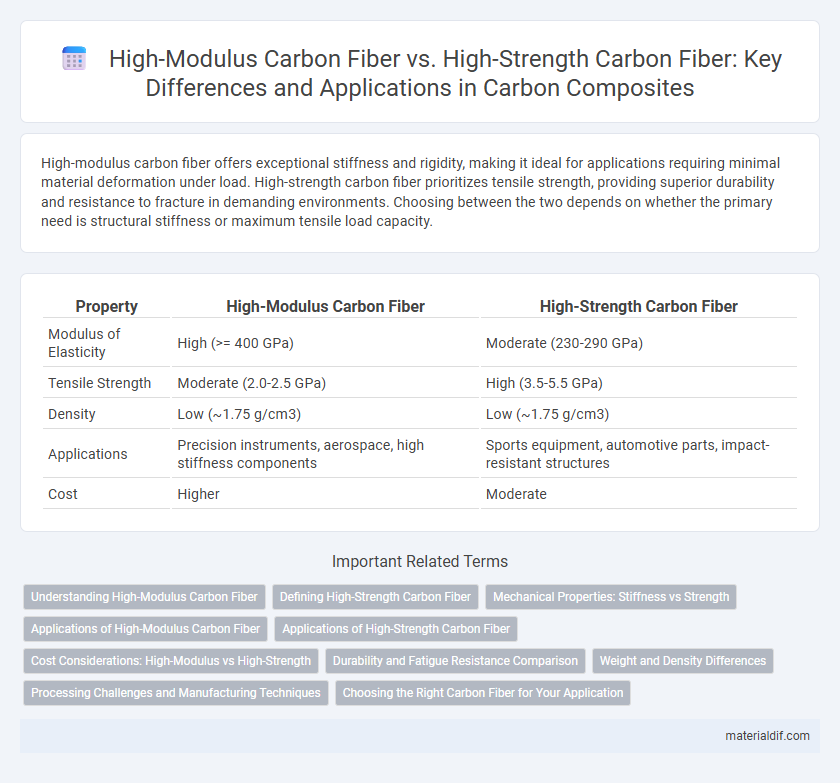

High-modulus carbon fiber offers exceptional stiffness and rigidity, making it ideal for applications requiring minimal material deformation under load. High-strength carbon fiber prioritizes tensile strength, providing superior durability and resistance to fracture in demanding environments. Choosing between the two depends on whether the primary need is structural stiffness or maximum tensile load capacity.

Table of Comparison

| Property | High-Modulus Carbon Fiber | High-Strength Carbon Fiber |

|---|---|---|

| Modulus of Elasticity | High (>= 400 GPa) | Moderate (230-290 GPa) |

| Tensile Strength | Moderate (2.0-2.5 GPa) | High (3.5-5.5 GPa) |

| Density | Low (~1.75 g/cm3) | Low (~1.75 g/cm3) |

| Applications | Precision instruments, aerospace, high stiffness components | Sports equipment, automotive parts, impact-resistant structures |

| Cost | Higher | Moderate |

Understanding High-Modulus Carbon Fiber

High-modulus carbon fiber offers superior stiffness, characterized by a tensile modulus typically exceeding 300 GPa, making it ideal for aerospace and high-performance automotive applications where rigidity is critical. Unlike high-strength carbon fiber, which prioritizes tensile strength up to 7 GPa, high-modulus variants emphasize minimal elongation under stress, enhancing structural stability. The production process of high-modulus carbon fiber involves advanced precursor materials and controlled thermal treatments to align molecular chains, resulting in fibers with enhanced tensile modulus and stiffness.

Defining High-Strength Carbon Fiber

High-strength carbon fiber is characterized by its exceptional tensile strength, typically exceeding 5,500 MPa, making it ideal for applications requiring superior load-bearing capacity and resistance to mechanical stress. Unlike high-modulus carbon fiber, which prioritizes stiffness with a modulus often above 300 GPa, high-strength fibers balance strength with adequate stiffness, enabling enhanced durability and impact resistance in aerospace, automotive, and sporting goods industries. Manufacturers emphasize high-strength carbon fibers like T700 and M40J grades for their optimal combination of toughness and performance under dynamic loads.

Mechanical Properties: Stiffness vs Strength

High-modulus carbon fiber exhibits superior stiffness due to its higher Young's modulus, making it ideal for applications requiring minimal deformation under load, such as aerospace and structural components. High-strength carbon fiber offers greater tensile strength, providing enhanced resistance to fracture and making it suitable for impact-resistant and high-stress environments. Choosing between high-modulus and high-strength carbon fiber depends on whether the application prioritizes stiffness or strength, influencing performance and durability in engineering designs.

Applications of High-Modulus Carbon Fiber

High-modulus carbon fiber, characterized by its superior stiffness and low thermal expansion, is extensively used in aerospace engineering for structural components requiring minimal deflection under stress. Its high rigidity makes it ideal for precision instruments, sporting equipment like racing bicycles and golf clubs, where stability and responsiveness are critical. Unlike high-strength carbon fiber, which prioritizes tensile strength, high-modulus variants enhance performance in applications demanding exceptional dimensional stability and vibration damping.

Applications of High-Strength Carbon Fiber

High-strength carbon fiber is widely used in aerospace structures, offering exceptional tensile strength and fatigue resistance critical for aircraft components and spacecraft. Its applications extend to automotive industries where it enhances crash safety and reduces overall vehicle weight. Sporting goods such as high-performance bicycles and golf clubs benefit from the durability and impact resistance provided by high-strength carbon fiber materials.

Cost Considerations: High-Modulus vs High-Strength

High-modulus carbon fiber generally incurs higher production costs due to its more complex manufacturing processes and the need for purer raw materials, making it significantly more expensive than high-strength carbon fiber. High-strength carbon fiber offers a cost-effective alternative by providing excellent tensile strength suitable for many applications while maintaining lower material and production costs. Choosing between high-modulus and high-strength carbon fibers depends largely on budget constraints and the specific performance requirements of the end product.

Durability and Fatigue Resistance Comparison

High-modulus carbon fiber exhibits superior stiffness and maintains structural integrity under repetitive stress, making it highly durable in applications requiring minimal deformation. High-strength carbon fiber offers enhanced tensile strength and better fatigue resistance, which is critical for components subjected to fluctuating loads and cyclic bending. The trade-off between stiffness and fatigue resistance is crucial when selecting carbon fiber types for aerospace, automotive, and sporting goods industries.

Weight and Density Differences

High-modulus carbon fiber offers superior stiffness with a density typically around 1.75 g/cm3, making it lighter and more rigid compared to high-strength carbon fiber, which has a slightly higher density near 1.80 g/cm3. The lower density of high-modulus fibers enhances weight reduction in aerospace and automotive applications where rigidity is critical. In contrast, high-strength carbon fiber prioritizes tensile strength but adds marginally more weight, impacting overall structural efficiency.

Processing Challenges and Manufacturing Techniques

High-modulus carbon fiber offers superior stiffness but presents significant processing challenges due to its brittleness, requiring precise tension control during layup to prevent fiber breakage. High-strength carbon fiber, while more ductile, demands advanced resin infusion techniques and careful curing cycles to optimize its tensile properties without compromising structural integrity. Manufacturing these fibers involves tailored processes like specialized woven fabric creation and autoclave curing to balance performance characteristics and production efficiency.

Choosing the Right Carbon Fiber for Your Application

High-modulus carbon fiber offers exceptional stiffness and rigidity, making it ideal for aerospace components and high-performance sporting goods where minimal flex is crucial. High-strength carbon fiber provides superior tensile strength and durability, suited for applications like automotive parts and structural reinforcements demanding impact resistance. Selecting the right carbon fiber depends on balancing stiffness versus strength requirements, weight limitations, and environmental conditions specific to the application's performance goals.

High-Modulus Carbon Fiber vs High-Strength Carbon Fiber Infographic

materialdif.com

materialdif.com