Machinable brass offers superior workability due to its fine grain structure, allowing for precise cutting, drilling, and shaping without compromising strength. Non-machinable brass typically contains higher levels of lead or other alloying elements, making it harder and more brittle, which limits its suitability for intricate machining processes. Choosing machinable brass ensures enhanced efficiency and accuracy in manufacturing components requiring tight tolerances.

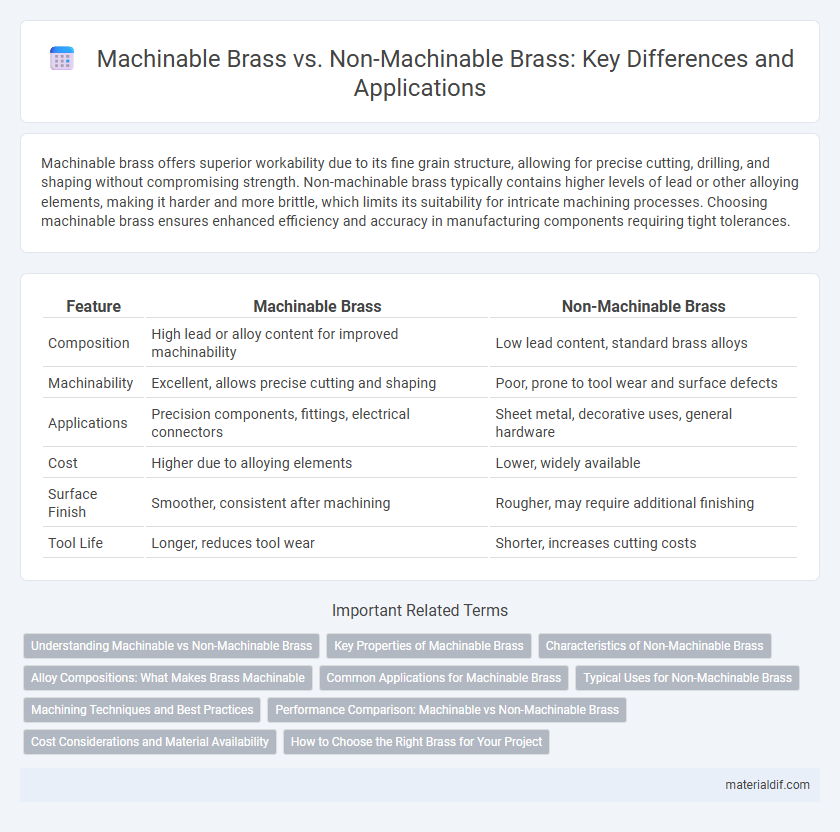

Table of Comparison

| Feature | Machinable Brass | Non-Machinable Brass |

|---|---|---|

| Composition | High lead or alloy content for improved machinability | Low lead content, standard brass alloys |

| Machinability | Excellent, allows precise cutting and shaping | Poor, prone to tool wear and surface defects |

| Applications | Precision components, fittings, electrical connectors | Sheet metal, decorative uses, general hardware |

| Cost | Higher due to alloying elements | Lower, widely available |

| Surface Finish | Smoother, consistent after machining | Rougher, may require additional finishing |

| Tool Life | Longer, reduces tool wear | Shorter, increases cutting costs |

Understanding Machinable vs Non-Machinable Brass

Machinable brass offers superior workability due to its fine grain structure and specific alloy composition, which reduces tool wear and enhances precision during machining processes. Non-machinable brass, often containing higher levels of lead or other additives, exhibits increased hardness and corrosion resistance but poses challenges such as increased tool wear and slower cutting speeds. Selecting between machinable and non-machinable brass depends on application requirements, prioritizing ease of fabrication versus mechanical strength and durability.

Key Properties of Machinable Brass

Machinable brass is characterized by its excellent machinability, high tensile strength, and good corrosion resistance, making it ideal for precision components. This type of brass typically contains lead or other additives that enhance chip breaking and reduce tool wear during machining processes. Its superior dimensional stability and thermal conductivity further contribute to consistent performance in manufacturing applications.

Characteristics of Non-Machinable Brass

Non-machinable brass is characterized by its high hardness and strength, which make it resistant to deformation but difficult to cut or shape using conventional machining processes. It typically contains higher amounts of copper and may include lead-free alloys, resulting in reduced machinability but improved corrosion resistance and thermal conductivity. This type of brass is often chosen for applications requiring durability and wear resistance rather than ease of fabrication.

Alloy Compositions: What Makes Brass Machinable

Machinable brass alloys typically contain lead (Pb) ranging from 1.5% to 3.5%, enhancing chip-breaking and reducing tool wear, with common compositions like C36000 featuring approximately 61.5% copper (Cu), 35.5% zinc (Zn), and lead additions. Non-machinable brass alloys, such as C26000, usually have higher copper and zinc content but lack lead, resulting in tougher materials that resist deformation but complicate machining processes. The presence and percentage of lead in the alloy composition directly influence machinability by improving lubricant film formation and internal chip control during cutting operations.

Common Applications for Machinable Brass

Machinable brass, known for its excellent workability and strength, is commonly used in precision components such as gears, valves, and fittings. Its ability to be easily shaped without compromising durability makes it ideal for electrical connectors and plumbing applications. The alloy's corrosion resistance also suits it for marine hardware and musical instruments.

Typical Uses for Non-Machinable Brass

Non-machinable brass is typically used in applications requiring excellent corrosion resistance and high strength, such as plumbing fittings, musical instruments, and decorative hardware. Its durability and resistance to dezincification make it ideal for marine environments and architectural components. Unlike machinable brass, it is often found in cast forms where intricate machining is unnecessary.

Machining Techniques and Best Practices

Machinable brass alloys such as C360 are favored for their excellent cutting properties, allowing high-speed machining with minimal tool wear and superior surface finish. Best practices include using sharp carbide tools, maintaining moderate cutting speeds between 150-200 surface feet per minute, and applying adequate lubrication to prevent chip welding and tool overheating. Non-machinable brass, typically high-leaded or containing additives for corrosion resistance, requires specialized methods like EDM or grinding to achieve precise tolerances.

Performance Comparison: Machinable vs Non-Machinable Brass

Machinable brass offers superior precision and ease of fabrication due to its enhanced composition, allowing for tighter tolerances and smoother finishes compared to non-machinable brass. Non-machinable brass, while typically more cost-effective, lacks the refined grain structure necessary for high-speed machining, resulting in increased tool wear and lower dimensional accuracy. Performance differences impact applications requiring intricate designs or high-volume production, where machinable brass ensures consistent quality and efficiency.

Cost Considerations and Material Availability

Machinable brass typically incurs higher costs due to its enhanced alloy composition that facilitates easier machining processes, reducing tool wear and production time. Non-machinable brass, while generally more affordable, may require specialized equipment and longer processing periods, impacting overall manufacturing expenses. Material availability for machinable brass is often more limited as it is produced in specific grades, whereas non-machinable brass is widely accessible in various standard forms and applications.

How to Choose the Right Brass for Your Project

Selecting the right brass for your project involves understanding the machinability and application requirements of machinable versus non-machinable brass. Machinable brass, often composed of alloys with lead like C360, offers excellent ease of cutting and shaping, making it ideal for components requiring precision and intricate details. Non-machinable brass varieties, such as architectural brass, prioritize corrosion resistance and aesthetic appeal but may require alternative fabrication methods like casting or forging, influencing the choice based on mechanical properties and project goals.

Machinable Brass vs Non-Machinable Brass Infographic

materialdif.com

materialdif.com