Brass tubing offers lightweight flexibility and is ideal for applications requiring fluid or gas transfer due to its hollow structure, while brass rod provides solid strength and durability for machining and structural uses. The choice between brass tubing and brass rod depends on whether the project prioritizes weight reduction and fluid dynamics or mechanical stability and precision shaping. Understanding these differences ensures optimal material selection for plumbing, decorative, or industrial manufacturing needs.

Table of Comparison

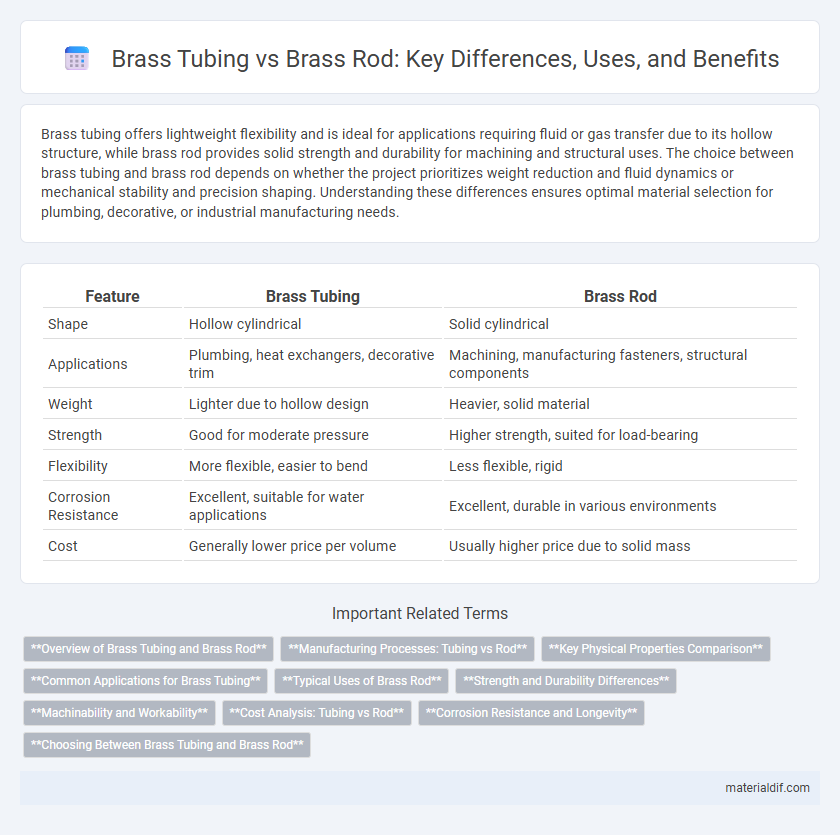

| Feature | Brass Tubing | Brass Rod |

|---|---|---|

| Shape | Hollow cylindrical | Solid cylindrical |

| Applications | Plumbing, heat exchangers, decorative trim | Machining, manufacturing fasteners, structural components |

| Weight | Lighter due to hollow design | Heavier, solid material |

| Strength | Good for moderate pressure | Higher strength, suited for load-bearing |

| Flexibility | More flexible, easier to bend | Less flexible, rigid |

| Corrosion Resistance | Excellent, suitable for water applications | Excellent, durable in various environments |

| Cost | Generally lower price per volume | Usually higher price due to solid mass |

Overview of Brass Tubing and Brass Rod

Brass tubing consists of hollow cylindrical shapes primarily used for fluid transport, HVAC systems, and decorative applications, offering flexibility and corrosion resistance. Brass rods are solid, cylindrical bars suited for machining, structural components, and manufacturing fittings due to their strength and durability. Both exhibit excellent thermal conductivity and machinability, but tubing serves different functional purposes compared to solid rods.

Manufacturing Processes: Tubing vs Rod

Brass tubing is typically produced through extrusion or drawing processes, where metal is forced through a die to create hollow, cylindrical shapes with consistent wall thickness. Brass rods are manufactured by hot or cold rolling and extrusion, resulting in solid, cylindrical bars with uniform diameter. The difference in manufacturing methods directly impacts their structural properties, with tubing requiring precision control for hollow sections and rods emphasizing solid material integrity.

Key Physical Properties Comparison

Brass tubing typically offers greater flexibility and lighter weight compared to brass rod, making it ideal for applications requiring precision bending and fluid transport. Brass rod boasts higher structural strength and rigidity due to its solid cross-section, essential for machining and load-bearing components. Both materials share excellent corrosion resistance and thermal conductivity, but the choice depends on whether dimensional stability or malleability is prioritized.

Common Applications for Brass Tubing

Brass tubing is commonly used in plumbing, HVAC systems, and instrumentation due to its corrosion resistance and excellent machinability. It is also prevalent in automotive fuel lines, musical instruments, and decorative architectural applications where flexibility and precision are essential. Compared to brass rod, brass tubing offers superior fluid flow capabilities and easier integration into complex assemblies.

Typical Uses of Brass Rod

Brass rods are commonly used in manufacturing precision components such as gears, valves, and fittings due to their excellent machinability and corrosion resistance. They serve in decorative applications and architectural hardware where durability and aesthetic appeal are essential. Industrial sectors also utilize brass rods for electrical connectors and musical instruments, leveraging their conductivity and acoustic properties.

Strength and Durability Differences

Brass tubing offers enhanced flexibility and resistance to impact due to its hollow structure, making it suitable for applications requiring lightweight yet strong materials. Brass rods provide superior tensile strength and durability because of their solid cross-section, ideal for load-bearing and structural uses. The choice between tubing and rod depends on balancing strength requirements with weight and form factor constraints in specific engineering projects.

Machinability and Workability

Brass tubing offers superior machinability due to its uniform wall thickness and consistent hollow structure, making it ideal for precise cutting and shaping applications. Brass rod, being solid, provides greater workability for heavy-duty machining processes like threading, turning, and bending where strength and durability are essential. Both forms exhibit excellent corrosion resistance and thermal conductivity, but the choice depends on specific project requirements for ease of machining or structural integrity.

Cost Analysis: Tubing vs Rod

Brass tubing generally costs more per linear foot than brass rod due to the added manufacturing processes such as extrusion and drawing, which create hollow structures. Brass rods offer a more economical choice for applications requiring solid sections since they involve simpler production methods and less material waste. Choosing between tubing and rod depends on specific project needs, with tubing favored for weight reduction and rod preferred for structural strength at a lower cost.

Corrosion Resistance and Longevity

Brass tubing exhibits superior corrosion resistance compared to brass rod due to its often thinner, more uniform alloy composition designed for fluid transport, reducing the risk of internal oxidation. The longevity of brass tubing is enhanced by its resistance to tarnishing and dezincification, especially in marine and industrial environments where exposure to moisture and chemicals is frequent. In contrast, brass rods, while durable, may be more prone to surface corrosion when exposed to harsh conditions due to their solid cross-section and potential for micro-cracks.

Choosing Between Brass Tubing and Brass Rod

Choosing between brass tubing and brass rod depends on the application's structural and design requirements; brass tubing offers hollow, lightweight characteristics ideal for fluid transport and decorative elements, while brass rod provides solid strength suited for machining and load-bearing components. Material properties such as corrosion resistance, machinability, and dimensional stability also influence the selection process, ensuring optimal performance in HVAC, plumbing, or fabrication projects. Cost considerations and ease of assembly play crucial roles, with tubing often being more economical for volume-based uses and rods preferred for precise, solid parts.

Brass Tubing vs Brass Rod Infographic

materialdif.com

materialdif.com