Naval brass contains a higher percentage of zinc and small amounts of tin, enhancing its corrosion resistance in marine environments compared to cartridge brass. Cartridge brass typically consists of about 70% copper and 30% zinc, offering excellent ductility and strength ideal for ammunition casings. The addition of tin in naval brass improves its durability against seawater, making it superior for naval applications.

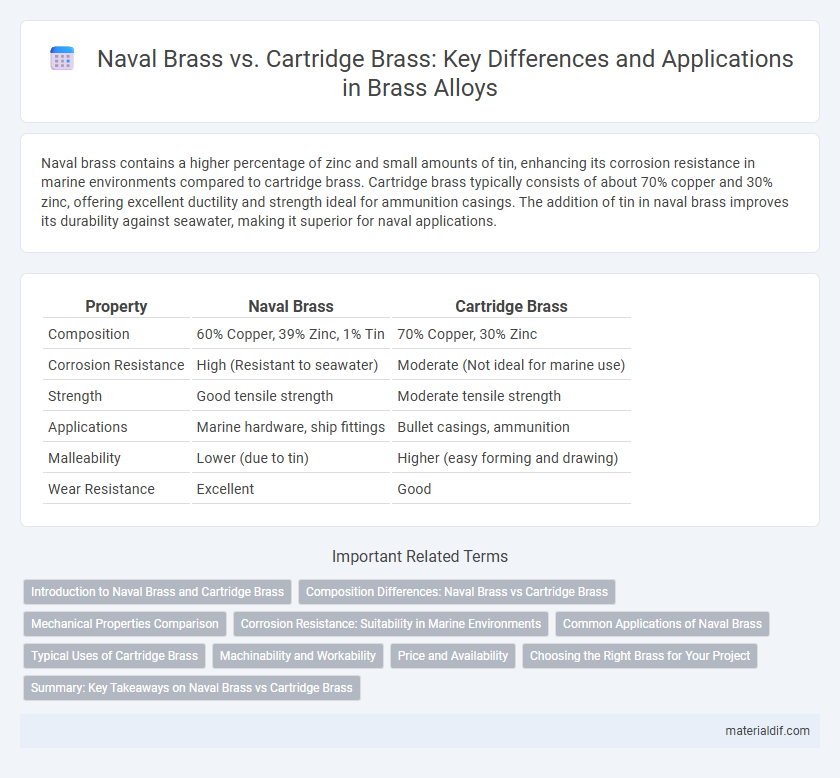

Table of Comparison

| Property | Naval Brass | Cartridge Brass |

|---|---|---|

| Composition | 60% Copper, 39% Zinc, 1% Tin | 70% Copper, 30% Zinc |

| Corrosion Resistance | High (Resistant to seawater) | Moderate (Not ideal for marine use) |

| Strength | Good tensile strength | Moderate tensile strength |

| Applications | Marine hardware, ship fittings | Bullet casings, ammunition |

| Malleability | Lower (due to tin) | Higher (easy forming and drawing) |

| Wear Resistance | Excellent | Good |

Introduction to Naval Brass and Cartridge Brass

Naval brass is a copper-zinc alloy typically containing about 60% copper, 39% zinc, and 1% tin, designed for enhanced corrosion resistance in marine environments. Cartridge brass consists of approximately 70% copper and 30% zinc, valued for its excellent ductility and strength, making it ideal for ammunition casings and industrial applications. Both alloys exhibit distinct mechanical properties and corrosion resistance due to their specific compositions and intended uses.

Composition Differences: Naval Brass vs Cartridge Brass

Naval brass typically consists of approximately 60% copper, 39% zinc, and 1% tin, enhancing its corrosion resistance and making it ideal for marine environments. Cartridge brass contains around 70% copper and 30% zinc, offering excellent ductility and strength suitable for ammunition casings. The presence of tin in naval brass improves resistance to dezincification, whereas cartridge brass prioritizes malleability and mechanical properties for forming processes.

Mechanical Properties Comparison

Naval brass typically contains about 60% copper, 39% zinc, and 1% tin, offering superior corrosion resistance and moderate strength, making it ideal for marine applications. Cartridge brass, with approximately 70% copper and 30% zinc, exhibits higher ductility and excellent workability, suitable for ammunition casings requiring reliable expansion and resilience. Mechanical properties such as tensile strength in naval brass range around 420 MPa, while cartridge brass can reach up to 485 MPa, reflecting their optimized compositions for different performance demands.

Corrosion Resistance: Suitability in Marine Environments

Naval brass, an alloy of copper, zinc, and small amounts of tin, exhibits superior corrosion resistance in marine environments compared to cartridge brass, which primarily consists of copper and zinc. The addition of tin in naval brass enhances its resistance to dezincification and saltwater-induced degradation, making it ideal for naval and marine applications such as ship fittings and underwater components. Cartridge brass, with higher zinc content and no tin, is more prone to corrosion and thus less suitable for prolonged exposure to saltwater conditions.

Common Applications of Naval Brass

Naval Brass, an alloy typically composed of 60% copper, 39% zinc, and 1% tin, is highly valued for its excellent corrosion resistance in seawater environments, making it ideal for marine hardware, ship fittings, and propellers. Its superior strength and resistance to dezincification distinguish it from Cartridge Brass, which is mainly used in ammunition casings and decorative items. Naval Brass is commonly applied in underwater fasteners, valve components, and pump parts where durability against saltwater corrosion is critical.

Typical Uses of Cartridge Brass

Cartridge brass, an alloy typically composed of 70% copper and 30% zinc, is predominantly used in ammunition casings due to its excellent ductility, corrosion resistance, and ability to withstand high pressures. Its malleability and strength make it ideal for manufacturing cartridge cases, bullet jackets, and other precision components in the firearms industry. Beyond military applications, cartridge brass is also utilized in decorative hardware, musical instruments, and plumbing fittings where durability and aesthetic appeal are essential.

Machinability and Workability

Naval brass, typically composed of 60% copper, 39% zinc, and 1% tin, exhibits superior corrosion resistance and better machinability due to its tin content, making it ideal for marine applications. Cartridge brass, with approximately 70% copper and 30% zinc, offers excellent workability and high strength, providing easier forming and shaping for ammunition casings. The tin in naval brass enhances wear resistance but slightly reduces ductility compared to cartridge brass, which balances strength and malleability for efficient machining and forming processes.

Price and Availability

Naval brass typically costs more than cartridge brass due to its higher copper and zinc content combined with added tin, enhancing corrosion resistance but increasing material expenses. Cartridge brass is widely available and more affordable, commonly used for ammunition casings because of its excellent ductility and ease of manufacturing. Supply chain stability favors cartridge brass, making it easier to procure in large quantities compared to the more specialized naval brass.

Choosing the Right Brass for Your Project

Naval brass, known for its high corrosion resistance due to its copper-zinc-tin alloy composition, is ideal for marine and outdoor applications where durability against saltwater is essential. Cartridge brass, with its higher zinc content and excellent ductility, is preferred for manufacturing ammunition casings and precision-engineered components that require superior formability and strength. Selecting the right brass depends on balancing corrosion resistance and mechanical properties to ensure optimal performance in your specific project environment.

Summary: Key Takeaways on Naval Brass vs Cartridge Brass

Naval brass typically contains 60% copper, 39% zinc, and 1% tin, providing superior corrosion resistance and strength, making it ideal for marine environments. Cartridge brass, composed of approximately 70% copper and 30% zinc, offers excellent ductility and machinability, which is crucial for ammunition casing production. Understanding the distinct composition and properties of naval brass and cartridge brass guides material selection for applications requiring durability or forming ease.

Naval Brass vs Cartridge Brass Infographic

materialdif.com

materialdif.com