Phosphor bronze offers superior corrosion resistance and strength due to its tin and phosphorus content, making it ideal for marine and electrical applications. Muntz metal, an alloy of copper and zinc with a small amount of iron, provides excellent durability and is primarily used in shipbuilding and architectural features. Choosing between these materials depends on the specific requirements for toughness, machinability, and resistance to environmental factors.

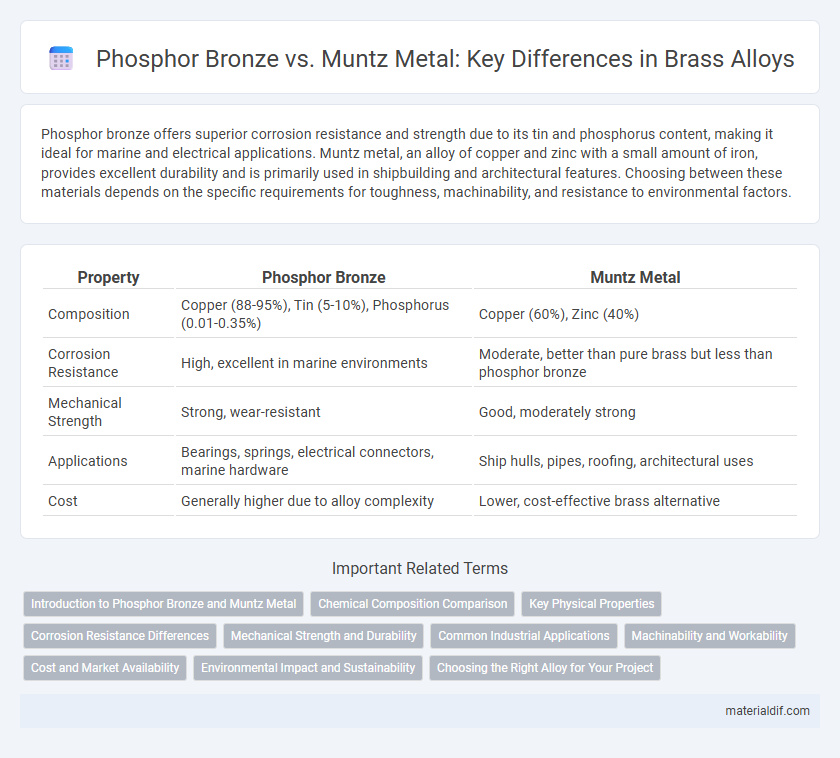

Table of Comparison

| Property | Phosphor Bronze | Muntz Metal |

|---|---|---|

| Composition | Copper (88-95%), Tin (5-10%), Phosphorus (0.01-0.35%) | Copper (60%), Zinc (40%) |

| Corrosion Resistance | High, excellent in marine environments | Moderate, better than pure brass but less than phosphor bronze |

| Mechanical Strength | Strong, wear-resistant | Good, moderately strong |

| Applications | Bearings, springs, electrical connectors, marine hardware | Ship hulls, pipes, roofing, architectural uses |

| Cost | Generally higher due to alloy complexity | Lower, cost-effective brass alternative |

Introduction to Phosphor Bronze and Muntz Metal

Phosphor bronze is an alloy of copper with 0.5-11% tin and 0.01-0.35% phosphorus, known for its toughness, low friction, and fine grain structure used in electrical components and springs. Muntz Metal, also called Yellow Metal, is a brass alloy consisting of approximately 60% copper and 40% zinc, prized for its corrosion resistance and strength, mainly utilized in shipbuilding and marine hardware. Both alloys serve distinct industrial applications due to their unique compositions and mechanical properties.

Chemical Composition Comparison

Phosphor bronze primarily consists of approximately 90-95% copper, 5-10% tin, and a small percentage (around 0.01-0.35%) of phosphorus, which enhances its strength and wear resistance. Muntz metal, on the other hand, contains about 60% copper, 40% zinc, and trace amounts of iron, providing a balance of strength and corrosion resistance with lower cost. The higher tin and phosphorus content in phosphor bronze results in superior fatigue resistance compared to the zinc-rich composition of Muntz metal.

Key Physical Properties

Phosphor bronze exhibits high tensile strength and excellent corrosion resistance due to its copper-tin-phosphorus alloy composition, making it ideal for springs and electrical connectors. Muntz metal, an alloy of copper and zinc with approx. 60% copper, offers superior malleability and good wear resistance, commonly used in marine applications and ship hulls. Phosphor bronze typically has higher hardness and fatigue resistance compared to Muntz metal, which excels in ductility and ease of machining.

Corrosion Resistance Differences

Phosphor bronze exhibits superior corrosion resistance compared to Muntz metal due to its higher copper and tin content, which forms a protective oxide layer that prevents further oxidation. Muntz metal, an alloy primarily composed of copper and zinc, is more prone to dezincification and surface corrosion in marine environments. This makes phosphor bronze a preferred choice for applications requiring enhanced durability against corrosive agents like saltwater and industrial chemicals.

Mechanical Strength and Durability

Phosphor bronze exhibits superior mechanical strength and corrosion resistance due to its phosphorus content, making it ideal for applications requiring high durability and wear resistance. Muntz metal, an alloy of copper and zinc with about 40% zinc, offers good tensile strength but lower corrosion resistance compared to phosphor bronze, limiting its durability in harsh conditions. The mechanical robustness of phosphor bronze supports long-term performance in dynamic and mechanical stress environments, whereas Muntz metal is more suited to marine applications where cost-effectiveness and moderate strength are priorities.

Common Industrial Applications

Phosphor bronze is widely used in electrical connectors, springs, and marine hardware due to its excellent corrosion resistance and high fatigue strength. Muntz metal, an alloy of copper and zinc, finds common applications in shipbuilding, roofing, and architectural structures because of its durability and resistance to seawater corrosion. Both materials serve critical roles in manufacturing industries where mechanical strength and resistance to environmental factors are essential.

Machinability and Workability

Phosphor bronze offers superior machinability due to its fine grain structure and lubricating properties from phosphorus content, enabling precise and smooth cutting operations. Muntz metal, a high-copper brass alloy, exhibits excellent workability with good malleability and ductility, making it suitable for forming and shaping but slightly less amenable to intricate machining. Both alloys serve distinct industrial needs, with phosphor bronze favored for components requiring detailed machining and muntz metal preferred for larger, formed parts.

Cost and Market Availability

Phosphor bronze typically costs more than Muntz metal due to its higher copper and tin content, making it suitable for applications requiring superior corrosion resistance and strength. Muntz metal, an alloy of copper and zinc, is more widely available and economical, often used in marine and architectural applications where budget constraints are critical. Market availability for Muntz metal is high because of its established use and cost-effectiveness, whereas phosphor bronze is less readily stocked but valued for precision and durability.

Environmental Impact and Sustainability

Phosphor bronze demonstrates a lower environmental impact due to its superior corrosion resistance, which extends product lifespan and reduces waste. Muntz metal, an alloy of copper and zinc, requires more frequent replacement and recycling due to its susceptibility to dezincification and corrosion in marine environments. Sustainable practices favor phosphor bronze for its durability and recyclability, contributing to resource conservation and lower ecological footprints.

Choosing the Right Alloy for Your Project

Phosphor bronze offers superior corrosion resistance and excellent fatigue durability, making it ideal for electrical connectors and marine hardware. Muntz metal, composed primarily of copper and zinc, provides high strength and is well-suited for applications like shipbuilding and architectural cladding. Selecting the right alloy depends on required mechanical properties, environmental exposure, and specific project demands.

Phosphor Bronze vs Muntz Metal Infographic

materialdif.com

materialdif.com