Muntz Metal, an alloy consisting of approximately 60% copper and 40% zinc with a small amount of iron, is highly valued for its strength, corrosion resistance, and affordability in marine applications. Naval Brass typically contains a higher copper content (around 60-70%) combined with zinc and a small percentage of tin, offering enhanced resistance to dezincification and improved durability in saltwater environments. Choosing between Muntz Metal and Naval Brass depends on specific marine conditions, with Naval Brass preferred for environments requiring superior resistance to corrosion and Muntz Metal favored for cost-effective structural components.

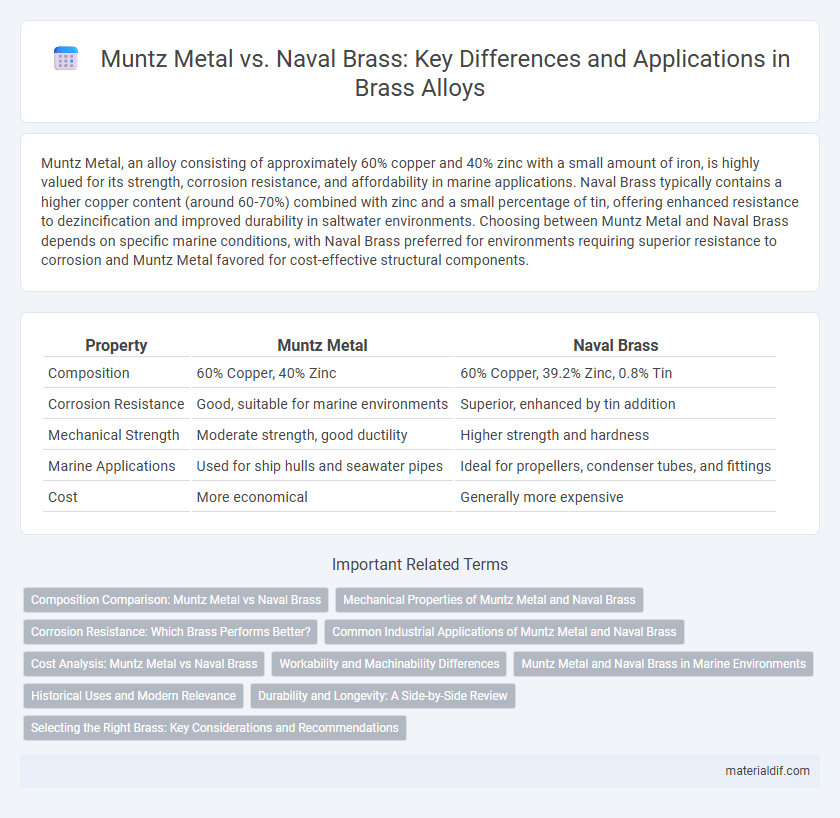

Table of Comparison

| Property | Muntz Metal | Naval Brass |

|---|---|---|

| Composition | 60% Copper, 40% Zinc | 60% Copper, 39.2% Zinc, 0.8% Tin |

| Corrosion Resistance | Good, suitable for marine environments | Superior, enhanced by tin addition |

| Mechanical Strength | Moderate strength, good ductility | Higher strength and hardness |

| Marine Applications | Used for ship hulls and seawater pipes | Ideal for propellers, condenser tubes, and fittings |

| Cost | More economical | Generally more expensive |

Composition Comparison: Muntz Metal vs Naval Brass

Muntz Metal consists primarily of 60% copper and 40% zinc, offering high strength and corrosion resistance ideal for marine applications. Naval Brass contains about 60% copper, 39% zinc, and 1% tin, adding enhanced resistance to dezincification and improved durability in seawater environments. The addition of tin in Naval Brass provides superior protection against corrosion compared to the simpler composition of Muntz Metal.

Mechanical Properties of Muntz Metal and Naval Brass

Muntz Metal exhibits superior tensile strength, typically around 350 to 450 MPa, combined with excellent corrosion resistance and good machinability, making it ideal for marine applications. Naval Brass offers higher corrosion resistance and enhanced wear resistance due to its 60% copper, 39% zinc, and 1% tin composition, with tensile strength ranging from 450 to 550 MPa. Both alloys provide robust mechanical properties, but Muntz Metal is favored for structural components requiring moderate strength and high corrosion protection, while Naval Brass is preferred where higher strength and resistance to dezincification are critical.

Corrosion Resistance: Which Brass Performs Better?

Muntz Metal, composed of approximately 60% copper and 40% zinc with small amounts of iron, exhibits superior corrosion resistance in marine environments due to its added iron content that enhances protective oxide layer formation. Naval Brass, containing around 60% copper, 39% zinc, and 1% tin, also offers excellent corrosion resistance, particularly against dezincification and stress corrosion cracking in seawater. When comparing both, Naval Brass generally performs better in aggressive saltwater conditions because the tin content provides extra protection against dezincification, making it the preferred choice for critical marine applications.

Common Industrial Applications of Muntz Metal and Naval Brass

Muntz Metal, an alloy of approximately 60% copper and 40% zinc with a small percentage of iron, is commonly used in marine hardware, roofing, and decorative architectural elements due to its excellent corrosion resistance and strength. Naval Brass, containing about 60% copper, 39% zinc, and 1% tin, is favored in shipbuilding, marine fasteners, and pump components for its superior resistance to seawater corrosion and enhanced mechanical properties. Both alloys serve critical roles in industries requiring durability in harsh environments, with Muntz Metal often chosen for structural applications and Naval Brass preferred for precision components exposed to saltwater.

Cost Analysis: Muntz Metal vs Naval Brass

Muntz Metal typically offers a lower cost compared to Naval Brass due to its higher copper content and simpler alloy composition, making it more budget-friendly for large-scale industrial applications. Naval Brass contains more zinc and tin, enhancing corrosion resistance and mechanical properties, which justifies its higher price in marine environments requiring durability. Cost analysis must consider not only initial material expenses but also long-term maintenance and replacement costs driven by environmental exposure and performance requirements.

Workability and Machinability Differences

Muntz Metal, an alloy composed mainly of copper and zinc with a small percentage of iron, exhibits superior corrosion resistance and moderate machinability, making it ideal for marine applications where durability is critical. Naval Brass, containing higher copper and zinc content with added tin, offers enhanced workability and better cold-forming properties, allowing easier shaping and bending without cracking. While Muntz Metal performs better under harsh seawater conditions, Naval Brass provides improved machinability for intricate components requiring precise fabrication.

Muntz Metal and Naval Brass in Marine Environments

Muntz Metal, an alloy of approximately 60% copper and 40% zinc with a small trace of iron, offers enhanced corrosion resistance and durability in marine environments compared to Naval Brass, which typically contains about 60% copper, 39% zinc, and 1% tin. The tin in Naval Brass provides superior resistance to dezincification and biofouling, making it suitable for seawater applications, yet Muntz Metal's higher zinc content improves strength and wear resistance under heavy mechanical stress. Both alloys resist saltwater corrosion effectively, but Muntz Metal is preferred for ship hulls and underwater fittings where abrasion and impact resistance are critical.

Historical Uses and Modern Relevance

Muntz Metal, an alloy composed of approximately 60% copper and 40% zinc, was historically favored for ship hulls and marine fastenings due to its superior resistance to corrosion and biofouling compared to Naval Brass, which contains about 60% copper, 39% zinc, and 1% tin. Naval Brass gained prominence in the early 20th century for marine hardware and ammunition casings owing to its enhanced strength and dezincification resistance. Today, Muntz Metal remains relevant in marine restoration projects and architectural applications, while Naval Brass is widely used in precision components and fittings requiring greater mechanical durability and corrosion resistance.

Durability and Longevity: A Side-by-Side Review

Muntz Metal, an alloy consisting of approximately 60% copper and 40% zinc with trace amounts of iron, offers superior durability due to its higher zinc content, making it highly resistant to corrosion and wear in marine environments. Naval Brass, composed of around 60% copper, 39% zinc, and 1% tin, provides excellent longevity through enhanced strength and exceptional resistance to dezincification, which is crucial for prolonged exposure to seawater. Comparing durability and longevity, Muntz Metal excels in general corrosion resistance, while Naval Brass outperforms in maintaining structural integrity under harsh saltwater conditions.

Selecting the Right Brass: Key Considerations and Recommendations

Muntz metal, an alloy composed of approximately 60% copper, 40% zinc, and trace amounts of iron, offers superior corrosion resistance and strength compared to naval brass, which typically contains about 60% copper, 39% zinc, and 1% tin for enhanced marine durability. When selecting brass for marine applications, prioritize Muntz metal for its excellent resistance to biofouling and dezincification, while naval brass is recommended for components requiring higher machinability and corrosion resistance in saltwater environments. Evaluating factors such as tensile strength, corrosion resistance, and maintenance requirements ensures optimal material performance tailored to specific maritime conditions.

Muntz Metal vs Naval Brass Infographic

materialdif.com

materialdif.com