Cartridge brass, primarily composed of 70% copper and 30% zinc, offers exceptional strength and corrosion resistance, making it ideal for ammunition casings and industrial applications. Architectural brass, with a lower zinc content and often alloyed with small amounts of other metals, emphasizes aesthetic appeal and workability for decorative elements and building materials. Both types balance durability and appearance, but cartridge brass prioritizes mechanical performance while architectural brass focuses on visual elegance and ease of fabrication.

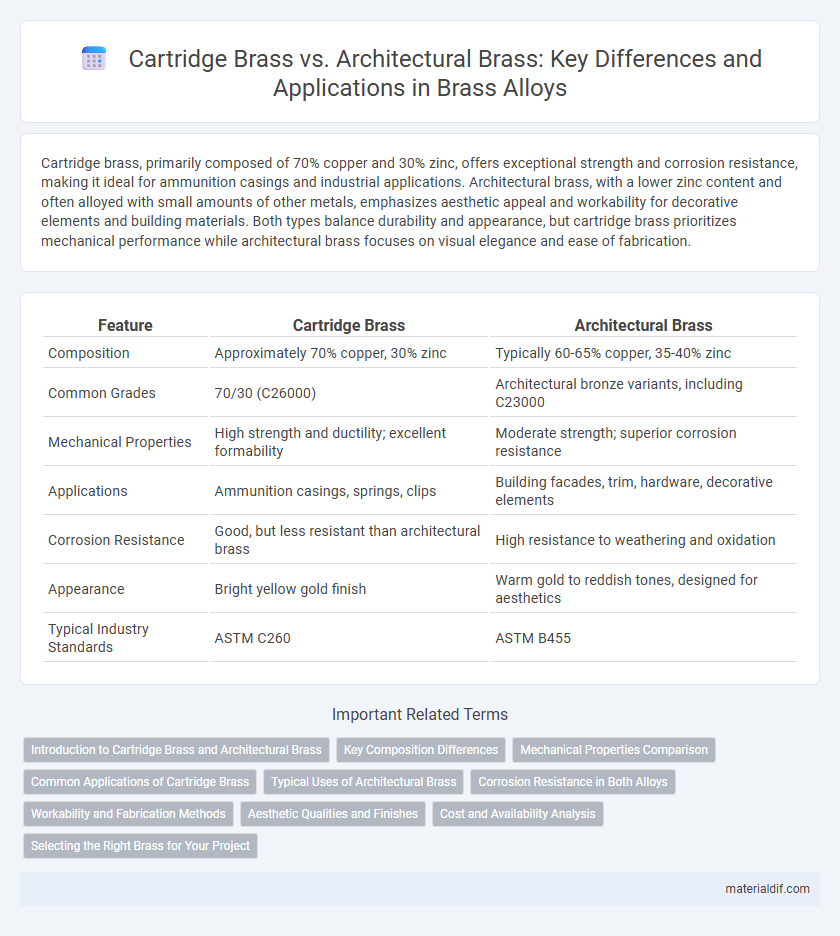

Table of Comparison

| Feature | Cartridge Brass | Architectural Brass |

|---|---|---|

| Composition | Approximately 70% copper, 30% zinc | Typically 60-65% copper, 35-40% zinc |

| Common Grades | 70/30 (C26000) | Architectural bronze variants, including C23000 |

| Mechanical Properties | High strength and ductility; excellent formability | Moderate strength; superior corrosion resistance |

| Applications | Ammunition casings, springs, clips | Building facades, trim, hardware, decorative elements |

| Corrosion Resistance | Good, but less resistant than architectural brass | High resistance to weathering and oxidation |

| Appearance | Bright yellow gold finish | Warm gold to reddish tones, designed for aesthetics |

| Typical Industry Standards | ASTM C260 | ASTM B455 |

Introduction to Cartridge Brass and Architectural Brass

Cartridge brass is a high-strength alloy primarily composed of 70% copper and 30% zinc, renowned for its excellent ductility and resistance to corrosion, making it ideal for manufacturing ammunition casings. Architectural brass, containing a similar copper-zinc ratio but often alloyed with small amounts of lead or tin, prioritizes enhanced machinability and polished aesthetics for applications in decorative building elements and fixtures. Both alloys offer distinct mechanical properties tailored to their respective industrial and design requirements.

Key Composition Differences

Cartridge brass primarily consists of 70% copper and 30% zinc, offering excellent ductility and corrosion resistance ideal for ammunition casings. Architectural brass typically contains a higher copper content, around 60-70%, with additional elements like lead to enhance machinability and surface finish. The variation in zinc and lead percentages directly influences mechanical properties and suitability for applications in structural design versus precision manufacturing.

Mechanical Properties Comparison

Cartridge brass typically exhibits higher tensile strength and better corrosion resistance, making it ideal for ammunition casings requiring durability under high stress. Architectural brass, while offering moderate strength, excels in formability and surface finish, suitable for decorative applications with less mechanical demand. Both alloys have comparable hardness, but cartridge brass generally withstands greater mechanical stress due to its carefully controlled copper-zinc composition.

Common Applications of Cartridge Brass

Cartridge brass, typically composed of 70% copper and 30% zinc, is primarily used in the manufacture of ammunition casings due to its excellent ductility and corrosion resistance. It is also widely employed in electrical connectors and plumbing fittings, where strong mechanical properties and ease of machining are crucial. Its balanced composition offers superior workability compared to architectural brass, which is often chosen for decorative and structural applications.

Typical Uses of Architectural Brass

Architectural brass is commonly used in decorative applications such as door hardware, handrails, and elevator panels due to its enhanced corrosion resistance and attractive finish. Unlike cartridge brass, which is primarily used for ammunition casings and industrial components, architectural brass offers superior workability and aesthetic qualities ideal for interior and exterior design elements. Its ability to maintain luster and resist tarnishing makes it a preferred choice in construction and architectural detailing.

Corrosion Resistance in Both Alloys

Cartridge brass, primarily composed of 70% copper and 30% zinc, demonstrates superior corrosion resistance due to its balanced alloy composition, making it ideal for ammunition and other high-stress applications. Architectural brass, often containing additional elements like lead and tin, offers enhanced machinability but slightly reduced corrosion resistance compared to cartridge brass. Both alloys resist oxidation, but the purity and zinc content in cartridge brass provide better durability in corrosive environments, especially in outdoor and marine settings.

Workability and Fabrication Methods

Cartridge brass, typically composed of 70% copper and 30% zinc, offers exceptional workability due to its balanced hardness and ductility, making it ideal for stamping, deep drawing, and machining in manufacturing processes. Architectural brass, often containing higher copper content and sometimes added elements like lead or tin, provides enhanced corrosion resistance and aesthetic appeal but requires more precise fabrication methods such as casting, extrusion, or specialized welding techniques to maintain its integrity. The selection between cartridge brass and architectural brass depends on the specific fabrication demands, where cartridge brass excels in mass production and architectural brass suits custom, durable, and visually refined applications.

Aesthetic Qualities and Finishes

Cartridge brass, primarily composed of 70% copper and 30% zinc, offers excellent malleability and a bright, golden-yellow finish that enhances its use in decorative applications requiring precision and durability. Architectural brass, with a lower zinc content, typically around 60% copper and 40% zinc, provides a richer, deeper color and superior corrosion resistance, making it ideal for exterior and high-traffic design elements. Both types can be finished through processes such as polishing, lacquering, or patination to achieve varying degrees of sheen, texture, and coloration tailored to specific aesthetic demands.

Cost and Availability Analysis

Cartridge brass, primarily composed of 70% copper and 30% zinc, is widely available and cost-effective due to its extensive use in ammunition manufacturing. Architectural brass, often alloyed with additional metals like lead for enhanced machinability and corrosion resistance, tends to be more expensive and less abundant because of its specialized application in construction and decorative features. Market prices fluctuate based on copper and zinc commodity rates, with cartridge brass benefiting from higher production volumes that lower unit costs compared to architectural brass.

Selecting the Right Brass for Your Project

Cartridge brass, known for its high copper and zinc content, offers excellent strength, corrosion resistance, and machinability, making it ideal for precision applications like ammunition casings. Architectural brass contains additional elements such as lead and other alloys, enhancing its malleability and appearance, favoring decorative and structural uses in building projects. Selecting the right brass depends on the required mechanical properties, environmental exposure, and aesthetic demands of your project to ensure durability and performance.

Cartridge Brass vs Architectural Brass Infographic

materialdif.com

materialdif.com