Lead-free brass offers a safer alternative to traditional brass by eliminating lead content, reducing health risks associated with lead exposure in plumbing and food-related applications. While traditional brass provides excellent machinability and corrosion resistance, lead-free brass meets stringent environmental regulations without compromising durability or performance. Manufacturers increasingly adopt lead-free brass to ensure compliance and promote safer consumer products.

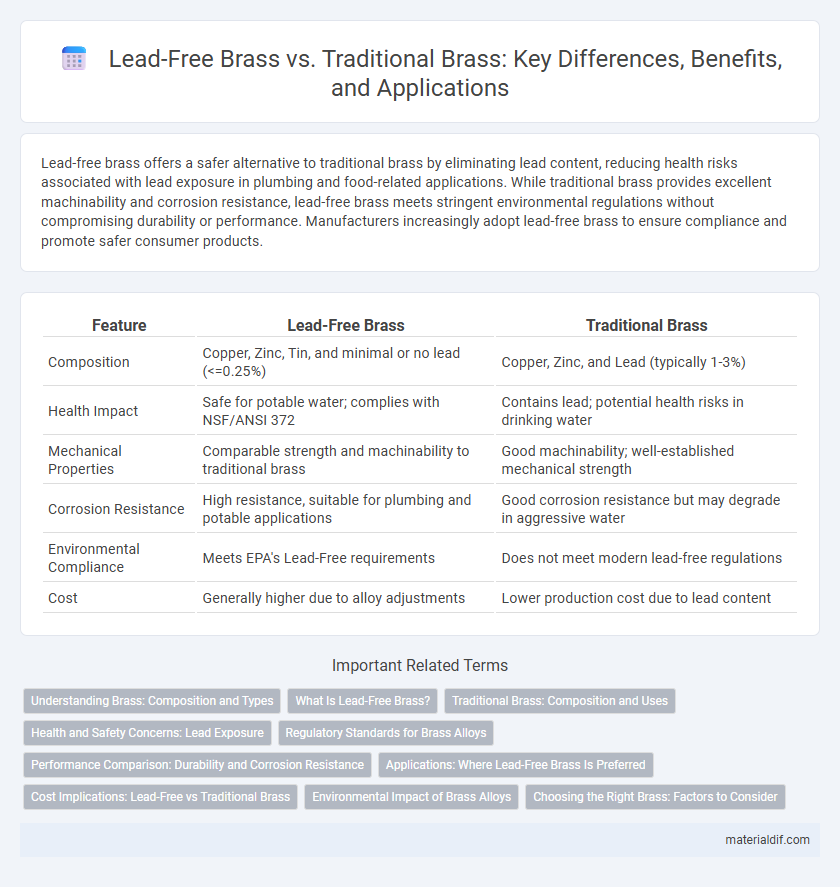

Table of Comparison

| Feature | Lead-Free Brass | Traditional Brass |

|---|---|---|

| Composition | Copper, Zinc, Tin, and minimal or no lead (<=0.25%) | Copper, Zinc, and Lead (typically 1-3%) |

| Health Impact | Safe for potable water; complies with NSF/ANSI 372 | Contains lead; potential health risks in drinking water |

| Mechanical Properties | Comparable strength and machinability to traditional brass | Good machinability; well-established mechanical strength |

| Corrosion Resistance | High resistance, suitable for plumbing and potable applications | Good corrosion resistance but may degrade in aggressive water |

| Environmental Compliance | Meets EPA's Lead-Free requirements | Does not meet modern lead-free regulations |

| Cost | Generally higher due to alloy adjustments | Lower production cost due to lead content |

Understanding Brass: Composition and Types

Lead-free brass consists primarily of copper, zinc, and other alloying elements such as silicon or tin, eliminating lead to meet health and environmental standards. Traditional brass typically contains 2-3% lead to enhance machinability and improve performance in manufacturing processes. Understanding the composition differences between lead-free and traditional brass is crucial for selecting the appropriate material based on application requirements and regulatory compliance.

What Is Lead-Free Brass?

Lead-free brass is an alloy composed primarily of copper and zinc, with restricted lead content below 0.05%, meeting stringent environmental and health regulations. It replaces traditional brass, which may contain up to 2% lead, to minimize lead exposure in potable water systems and consumer products. This eco-friendly alternative maintains mechanical strength and machinability while enhancing safety for applications like plumbing fixtures and food-contact surfaces.

Traditional Brass: Composition and Uses

Traditional brass consists primarily of copper and zinc, with typical compositions ranging from 60% to 70% copper and 30% to 40% zinc, often containing trace amounts of lead to improve machinability. This lead content, usually around 1-3%, enhances the metal's ease of cutting and shaping, making it ideal for precision components in plumbing, electrical fittings, and musical instruments. Widely used in manufacturing, traditional brass offers excellent corrosion resistance and electrical conductivity, but concerns over lead toxicity have prompted shifts toward lead-free alternatives.

Health and Safety Concerns: Lead Exposure

Lead-free brass significantly reduces health risks by eliminating lead content, which can leach into water supplies and pose severe toxicity concerns. Traditional brass typically contains small amounts of lead to enhance machinability, but this lead can contaminate drinking water and cause neurological damage, especially in children. Regulatory standards like the Safe Drinking Water Act promote lead-free brass to ensure safer plumbing materials and protect public health.

Regulatory Standards for Brass Alloys

Lead-free brass alloys comply with stringent regulatory standards such as the Safe Drinking Water Act (SDWA) in the United States, limiting lead content to 0.25% or less to ensure safer use in plumbing and potable water systems. Traditional brass, containing up to 2-3% lead, is increasingly restricted under regulations like the European Union's REACH and Germany's TrinkwV, which aim to reduce lead exposure due to health risks. Compliance with these standards drives the adoption of lead-free brass in manufacturing, balancing machinability with environmental and consumer safety requirements.

Performance Comparison: Durability and Corrosion Resistance

Lead-free brass offers enhanced corrosion resistance compared to traditional brass, which often contains lead that can accelerate degradation in certain environments. Durability in lead-free brass is generally comparable or superior due to improved alloy composition, making it ideal for applications in plumbing and potable water systems. Traditional brass, while still durable, may experience reduced lifespan in corrosive settings, highlighting lead-free brass as a more sustainable and reliable choice.

Applications: Where Lead-Free Brass Is Preferred

Lead-free brass is preferred in plumbing and potable water systems due to stringent health regulations restricting lead content, ensuring safer drinking water. Industrial applications involving food processing and medical equipment also favor lead-free brass to prevent contamination. Unlike traditional brass, lead-free variants provide compliance with standards such as NSF/ANSI 61 and the Safe Drinking Water Act.

Cost Implications: Lead-Free vs Traditional Brass

Lead-free brass typically incurs higher production costs due to the use of more expensive alloys and stricter manufacturing standards, impacting overall material expenses. Traditional brass, containing lead, offers a cost advantage with lower raw material and processing costs but faces increasing regulatory restrictions. Evaluating long-term cost implications also involves considering potential compliance penalties and health-related liabilities associated with lead content in traditional brass.

Environmental Impact of Brass Alloys

Lead-free brass alloys significantly reduce environmental contamination by eliminating toxic lead, which can leach into soil and water systems during manufacturing and disposal. Traditional brass containing lead poses health risks to ecosystems and humans due to its potential accumulation and bioavailability. Transitioning to lead-free brass supports sustainable practices by minimizing heavy metal pollution and complying with stricter environmental regulations globally.

Choosing the Right Brass: Factors to Consider

Choosing the right brass depends on factors such as corrosion resistance, machinability, and environmental impact. Lead-free brass offers enhanced safety for potable water applications due to the absence of harmful lead content, aligning with health regulations. Traditional brass provides excellent durability and ease of machining but may pose risks in sensitive uses where lead leaching is a concern.

Lead-Free Brass vs Traditional Brass Infographic

materialdif.com

materialdif.com