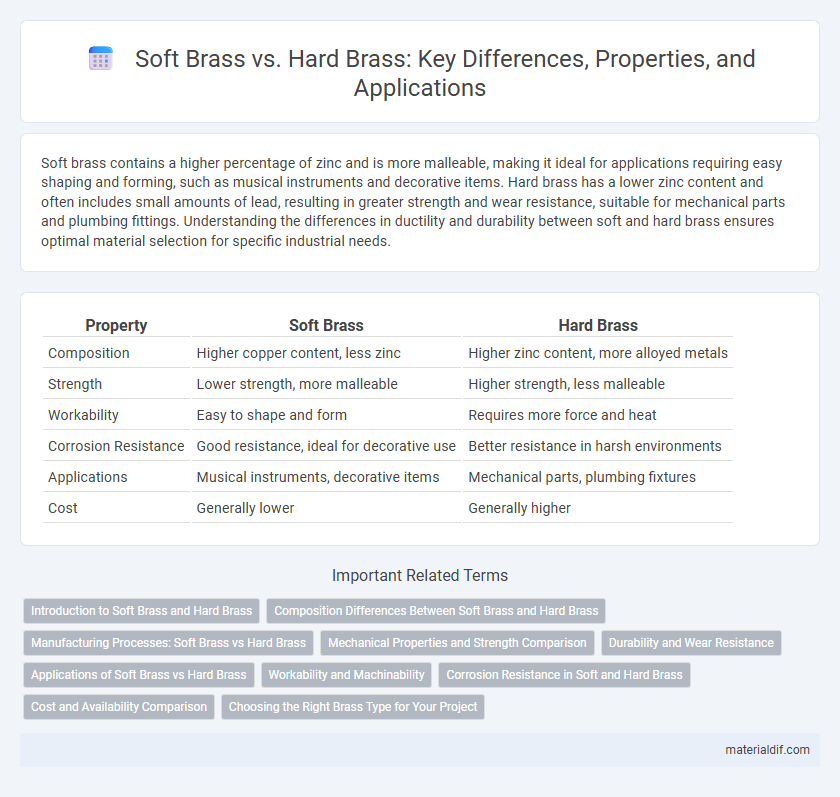

Soft brass contains a higher percentage of zinc and is more malleable, making it ideal for applications requiring easy shaping and forming, such as musical instruments and decorative items. Hard brass has a lower zinc content and often includes small amounts of lead, resulting in greater strength and wear resistance, suitable for mechanical parts and plumbing fittings. Understanding the differences in ductility and durability between soft and hard brass ensures optimal material selection for specific industrial needs.

Table of Comparison

| Property | Soft Brass | Hard Brass |

|---|---|---|

| Composition | Higher copper content, less zinc | Higher zinc content, more alloyed metals |

| Strength | Lower strength, more malleable | Higher strength, less malleable |

| Workability | Easy to shape and form | Requires more force and heat |

| Corrosion Resistance | Good resistance, ideal for decorative use | Better resistance in harsh environments |

| Applications | Musical instruments, decorative items | Mechanical parts, plumbing fixtures |

| Cost | Generally lower | Generally higher |

Introduction to Soft Brass and Hard Brass

Soft brass primarily consists of copper and zinc with a higher copper content, resulting in greater malleability and ease of forming, ideal for applications requiring intricate shapes and detailed craftsmanship. Hard brass contains a higher zinc concentration, making it stronger and more durable, suitable for structural and load-bearing uses. Understanding the difference in composition and mechanical properties between soft and hard brass is crucial for selecting the appropriate alloy for manufacturing, musical instruments, and decorative purposes.

Composition Differences Between Soft Brass and Hard Brass

Soft brass primarily contains about 60-65% copper and 35-40% zinc, which results in a more malleable and ductile alloy ideal for intricate forming processes. Hard brass increases the zinc content to around 40-45%, enhancing its strength and hardness while reducing its flexibility compared to soft brass. The variation in zinc concentration directly influences the mechanical properties, making soft brass suited for applications requiring ease of shaping and hard brass preferable for structural durability.

Manufacturing Processes: Soft Brass vs Hard Brass

Soft brass undergoes annealing during manufacturing, which involves heating and slow cooling to enhance its ductility and ease of machining. Hard brass is produced through cold working techniques such as rolling or drawing, increasing its strength and hardness by inducing strain hardening. The choice between soft and hard brass in manufacturing impacts formability, with soft brass favored for complex shapes and hard brass preferred for applications requiring durability and wear resistance.

Mechanical Properties and Strength Comparison

Soft brass exhibits lower tensile strength and greater ductility, making it ideal for applications requiring malleability and ease of fabrication. Hard brass contains a higher zinc content, resulting in increased hardness, tensile strength, and wear resistance suitable for mechanical components under stress. The mechanical properties of hard brass generally range from 350 to 500 MPa in tensile strength, while soft brass typically falls between 200 and 350 MPa.

Durability and Wear Resistance

Soft brass exhibits lower durability and wear resistance due to its higher malleability and reduced hardness, making it ideal for applications requiring easy shaping but less suited to heavy-duty use. Hard brass, alloyed with increased zinc or other elements, offers enhanced durability and wear resistance, maintaining structural integrity under mechanical stress and frequent contact. These properties make hard brass preferable for components subject to friction, impact, and long-term wear.

Applications of Soft Brass vs Hard Brass

Soft brass, known for its high malleability and corrosion resistance, is widely used in applications such as electrical connectors, musical instruments, and decorative hardware where ease of shaping and detailed work are essential. Hard brass offers superior strength and durability, making it suitable for heavy-duty fittings, gears, and valve components exposed to mechanical stress and wear. Manufacturers often select soft brass for intricate machining and forming processes, while hard brass is preferred in structural and load-bearing applications.

Workability and Machinability

Soft brass offers superior workability due to its lower hardness, making it easier to bend and shape for intricate designs. Hard brass provides enhanced machinability with greater strength, ideal for components requiring durability and precision cutting. Both types balance machinability and workability depending on the specific application and mechanical requirements.

Corrosion Resistance in Soft and Hard Brass

Soft brass exhibits superior corrosion resistance compared to hard brass due to its higher copper content and lower zinc percentage, which enhances its ability to withstand oxidizing environments. Hard brass, containing more zinc and sometimes other alloying elements, tends to be less resistant to corrosion, making it more prone to dezincification and surface degradation in harsh conditions. The corrosion resistance of brass alloys is crucial for applications in plumbing, marine, and electrical components where durability against chemical exposure is vital.

Cost and Availability Comparison

Soft brass generally costs more due to its higher copper content and greater malleability, making it ideal for intricate manufacturing processes. Hard brass is more affordable and widely available because it contains additional alloying elements like zinc, which increase its strength and reduce production costs. Manufacturers often choose hard brass when budget constraints and material availability are critical factors in large-scale production.

Choosing the Right Brass Type for Your Project

Soft brass, with its higher malleability and lower tensile strength, is ideal for intricate shaping and detailed work in decorative projects and musical instruments. Hard brass, known for its durability and resistance to wear, is better suited for structural components, plumbing fixtures, and applications requiring higher strength. Selecting the right brass type depends on the balance between flexibility and strength needed for your specific project's performance and longevity.

Soft Brass vs Hard Brass Infographic

materialdif.com

materialdif.com