Nickel silver offers superior corrosion resistance and a sleek, silvery appearance compared to yellow brass, which is known for its bright golden hue and excellent malleability. While yellow brass contains a higher copper content, giving it greater strength and ductility, nickel silver includes nickel and zinc, enhancing its durability and resistance to tarnish. Both alloys are popular in decorative and functional applications, but the choice depends on the desired aesthetic and environmental exposure.

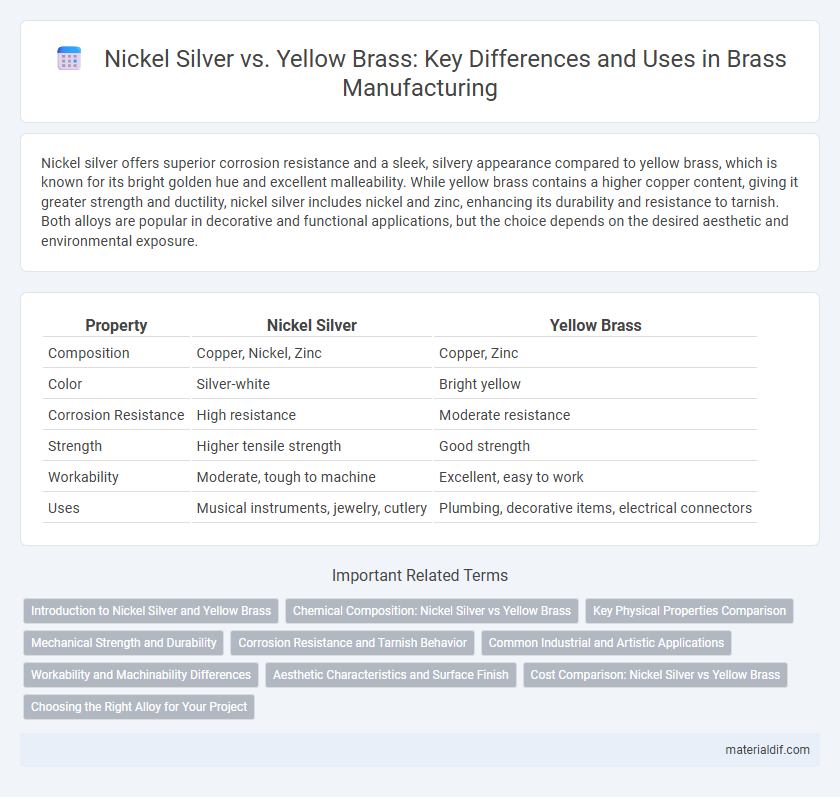

Table of Comparison

| Property | Nickel Silver | Yellow Brass |

|---|---|---|

| Composition | Copper, Nickel, Zinc | Copper, Zinc |

| Color | Silver-white | Bright yellow |

| Corrosion Resistance | High resistance | Moderate resistance |

| Strength | Higher tensile strength | Good strength |

| Workability | Moderate, tough to machine | Excellent, easy to work |

| Uses | Musical instruments, jewelry, cutlery | Plumbing, decorative items, electrical connectors |

Introduction to Nickel Silver and Yellow Brass

Nickel Silver, also known as German silver, is an alloy of copper, nickel, and zinc, prized for its silvery appearance and corrosion resistance without containing actual silver. Yellow Brass primarily consists of copper and zinc, featuring a warm golden hue and excellent machinability for diverse applications. Both materials offer unique aesthetic and mechanical properties suited for musical instruments, jewelry, and decorative hardware.

Chemical Composition: Nickel Silver vs Yellow Brass

Nickel Silver is an alloy primarily composed of copper, nickel, and zinc, typically containing 60% copper, 20% nickel, and 20% zinc, giving it a silver-like appearance without actual silver content. Yellow Brass consists mainly of copper and zinc, usually around 70% copper and 30% zinc, resulting in a warm golden-yellow hue. The increased nickel content in Nickel Silver enhances corrosion resistance and strength compared to Yellow Brass's more malleable and conductive properties.

Key Physical Properties Comparison

Nickel silver, an alloy composed primarily of copper, nickel, and zinc, exhibits greater corrosion resistance and higher tensile strength compared to yellow brass, which is a copper-zinc alloy. Yellow brass typically has better electrical conductivity and a warmer gold-like appearance but is softer and more prone to tarnishing. The denser composition of nickel silver results in a harder surface, making it ideal for applications requiring durability and wear resistance.

Mechanical Strength and Durability

Nickel silver exhibits higher mechanical strength and superior corrosion resistance compared to yellow brass, making it more durable in demanding environments. Yellow brass, an alloy primarily composed of copper and zinc, offers good machinability but is generally softer and less resistant to wear than nickel silver. Applications requiring enhanced toughness and longevity often favor nickel silver due to its improved hardness and resilience under mechanical stress.

Corrosion Resistance and Tarnish Behavior

Nickel silver exhibits superior corrosion resistance compared to yellow brass due to its higher nickel content, which forms a protective oxide layer that prevents degradation. Yellow brass, composed primarily of copper and zinc, is more prone to tarnishing and greenish patina formation when exposed to moisture and air over time. Both materials require maintenance, but nickel silver maintains a brighter finish longer under corrosive environments such as marine or industrial settings.

Common Industrial and Artistic Applications

Nickel silver, an alloy of copper, nickel, and zinc, offers superior corrosion resistance and a silvery finish ideal for musical instruments, jewelry, and decorative hardware. Yellow brass, composed primarily of copper and zinc, is favored in plumbing, marine fittings, and architectural accents due to its excellent machinability and bright golden appearance. Both materials are widely used in industrial and artistic applications where durability and aesthetic appeal are critical.

Workability and Machinability Differences

Nickel silver, an alloy of copper, nickel, and zinc, offers superior corrosion resistance and moderate machinability compared to yellow brass, which primarily consists of copper and zinc and excels in workability due to its higher malleability. Yellow brass tends to deform more easily under mechanical stress, making it ideal for forging and bending operations, whereas nickel silver's firmer structure provides better stability during precision machining and cutting processes. These differences make yellow brass preferable for forming intricate shapes, while nickel silver suits applications demanding tighter tolerances and smoother finishes in machining.

Aesthetic Characteristics and Surface Finish

Nickel silver exhibits a bright, silvery-white appearance with a smooth, reflective surface finish that enhances its modern aesthetic appeal, often used in decorative applications and musical instruments. Yellow brass, composed primarily of copper and zinc, features a warm, golden-yellow hue with a natural luster that develops a rich patina over time, favored for traditional and vintage designs. Both materials offer excellent machinability and polishability, but nickel silver maintains a consistent shine without tarnishing, while yellow brass may require regular maintenance to preserve its vibrant color.

Cost Comparison: Nickel Silver vs Yellow Brass

Nickel silver is generally more expensive than yellow brass due to its higher nickel content and corrosion-resistant properties, which increase material and manufacturing costs. Yellow brass, composed primarily of copper and zinc, offers a cost-effective option with good machinability and durability, making it popular for budget-conscious projects. Comparing prices, nickel silver typically commands a premium but benefits applications requiring enhanced aesthetic appeal and resistance to tarnishing.

Choosing the Right Alloy for Your Project

Nickel silver offers a silver-like appearance with superior corrosion resistance, making it ideal for decorative applications requiring durability and low maintenance. Yellow brass, composed primarily of copper and zinc, provides excellent machinability and a warm golden tone, perfect for projects emphasizing aesthetic appeal and workability. Selecting the right alloy depends on factors such as environmental exposure, desired color, mechanical properties, and cost considerations.

Nickel Silver vs Yellow Brass Infographic

materialdif.com

materialdif.com