Free-cutting brass contains lead additives that improve machinability and reduce tool wear, making it ideal for precision components requiring easy fabrication. Muntz metal, a brass alloy with higher copper content and zinc, offers excellent corrosion resistance and strength, commonly used in marine applications. Choosing between the two depends on balancing ease of machining with durability and environmental exposure.

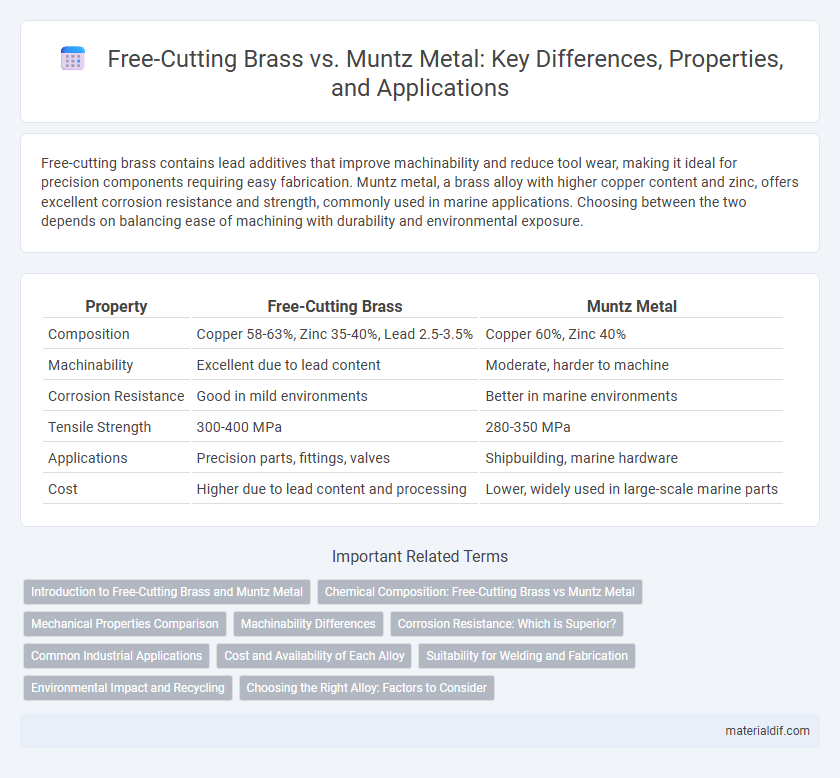

Table of Comparison

| Property | Free-Cutting Brass | Muntz Metal |

|---|---|---|

| Composition | Copper 58-63%, Zinc 35-40%, Lead 2.5-3.5% | Copper 60%, Zinc 40% |

| Machinability | Excellent due to lead content | Moderate, harder to machine |

| Corrosion Resistance | Good in mild environments | Better in marine environments |

| Tensile Strength | 300-400 MPa | 280-350 MPa |

| Applications | Precision parts, fittings, valves | Shipbuilding, marine hardware |

| Cost | Higher due to lead content and processing | Lower, widely used in large-scale marine parts |

Introduction to Free-Cutting Brass and Muntz Metal

Free-cutting brass is a high-lead alloy known for its excellent machinability and smooth surface finish, commonly used in precision components requiring easy shaping and minimal tool wear. Muntz metal, an alloy of approximately 60% copper and 40% zinc, offers superior corrosion resistance and strength, often utilized in marine and architectural applications. Both materials showcase distinct properties that cater to different industrial needs, with free-cutting brass optimized for manufacturing efficiency and Muntz metal valued for durability and environmental resilience.

Chemical Composition: Free-Cutting Brass vs Muntz Metal

Free-Cutting Brass typically contains a higher percentage of lead, around 2.5% to 4%, which enhances machinability without compromising corrosion resistance, whereas Muntz Metal comprises approximately 60% copper and 40% zinc, with minimal lead content, emphasizing strength and wear resistance. The lead in Free-Cutting Brass acts as a lubricant during machining, facilitating faster production and smoother surface finishes compared to Muntz Metal. Muntz Metal's specific copper-zinc ratio provides superior structural integrity for applications demanding durability under mechanical stress.

Mechanical Properties Comparison

Free-cutting brass offers superior machinability due to its higher lead content, enhancing tool life and reducing cutting forces compared to Muntz metal. Muntz metal, an alpha-beta brass alloy, provides greater strength and wear resistance, making it suitable for heavy-duty applications. The mechanical properties balance in free-cutting brass favors precision and efficiency, while Muntz metal prioritizes durability and structural integrity.

Machinability Differences

Free-cutting brass exhibits superior machinability due to its high sulfur or lead content, which provides excellent chip breaking and reduces tool wear compared to Muntz metal. Muntz metal, an alpha-beta brass alloy with 60% copper and 40% zinc, offers lower machinability and tends to produce longer, stringy chips that challenge cutting tools. The enhanced machinability of free-cutting brass makes it ideal for precision components requiring faster production rates and reduced manufacturing costs.

Corrosion Resistance: Which is Superior?

Free-cutting brass, an alloy primarily composed of copper, zinc, and lead, offers moderate corrosion resistance suitable for general applications, but Muntz metal, containing approximately 60% copper and 40% zinc, exhibits superior corrosion resistance especially in marine environments due to its high copper content and specific alloy composition. The presence of lead in free-cutting brass improves machinability but can create micro-galvanic cells that slightly reduce corrosion resistance compared to the more homogeneous structure of Muntz metal. Consequently, for applications requiring enhanced durability against saltwater and atmospheric corrosion, Muntz metal is the preferred choice over free-cutting brass.

Common Industrial Applications

Free-Cutting Brass is widely used in precision machining for components such as screws, nuts, and fittings due to its excellent machinability and resistance to corrosion. Muntz Metal, a high-copper alloy with zinc and a small amount of lead, finds common applications in marine hardware, shipbuilding, and roofing for its superior strength and durability in harsh environments. Both materials serve critical roles in industrial manufacturing, with Free-Cutting Brass preferred for complex, detailed parts and Muntz Metal favored for structural and outdoor uses.

Cost and Availability of Each Alloy

Free-cutting brass, known for its high machinability due to added lead, generally costs more than Muntz metal but offers easier processing and less machining wear. Muntz metal, a traditional brass alloy with higher copper content, tends to be more widely available and less expensive, making it a cost-effective option for large-scale applications. Availability varies regionally, with Muntz metal commonly stocked in bulk by metal suppliers, while free-cutting brass may require special orders or have higher lead times.

Suitability for Welding and Fabrication

Free-cutting brass, containing lead additives, offers excellent machinability and is less prone to cracking during welding, making it ideal for precision fabrication and intricate components. Muntz metal, an alloy of copper and zinc with higher zinc content, presents challenges in welding due to its tendency to oxidize and crack but provides superior strength for structural applications. Selecting the appropriate alloy depends on the balance between ease of fabrication and mechanical requirements for the intended application.

Environmental Impact and Recycling

Free-cutting brass, known for its high machinability due to added lead content, presents environmental challenges related to lead pollution and limited recyclability. Muntz metal, an alloy primarily of copper and zinc with minimal additives, offers better recyclability and a lower environmental footprint during processing. Choosing Muntz metal supports sustainable manufacturing practices due to its reduced toxic waste and higher recycling efficiency.

Choosing the Right Alloy: Factors to Consider

Choosing the right alloy between free-cutting brass and Muntz metal depends on machinability, corrosion resistance, and mechanical properties. Free-cutting brass offers superior machinability with lead content enhancing ease of cutting, ideal for precision components, while Muntz metal provides higher strength and excellent resistance to marine corrosion suitable for structural applications. Evaluating factors such as intended use environment, required mechanical performance, and ease of manufacturing ensures optimal alloy selection for specific industrial needs.

Free-Cutting Brass vs Muntz Metal Infographic

materialdif.com

materialdif.com