Machinable brass is specifically designed for ease of cutting, drilling, and shaping, making it ideal for precision parts and mechanical components. Architectural brass emphasizes aesthetic qualities such as polish, color, and corrosion resistance, commonly used in decorative elements like handrails and fixtures. Both types offer distinct advantages, with machinable brass prioritizing functionality and architectural brass enhancing visual appeal.

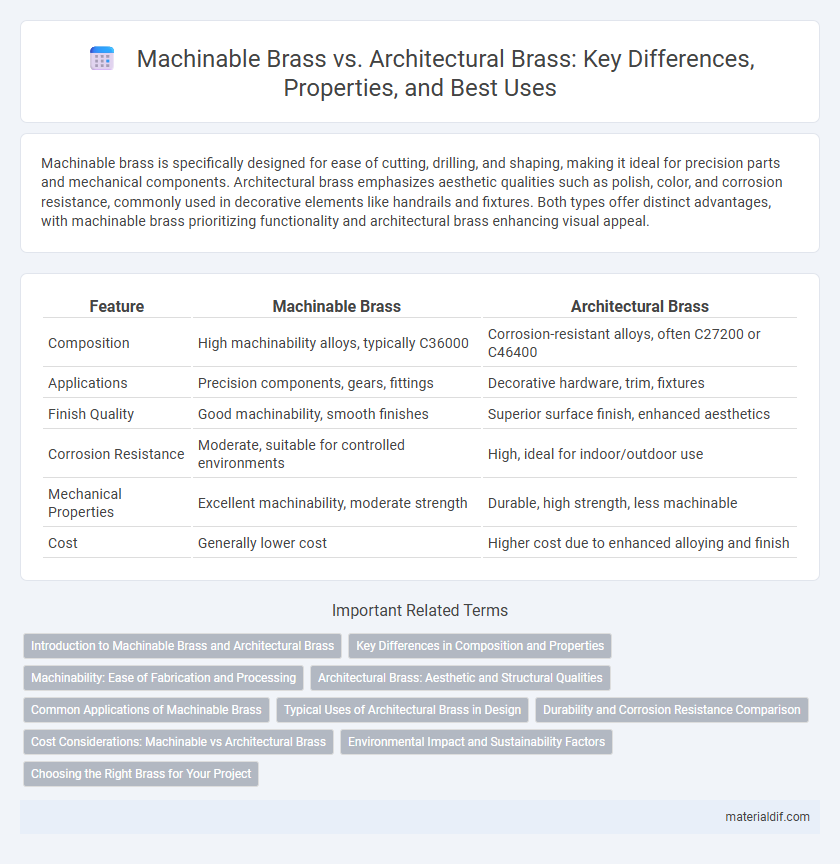

Table of Comparison

| Feature | Machinable Brass | Architectural Brass |

|---|---|---|

| Composition | High machinability alloys, typically C36000 | Corrosion-resistant alloys, often C27200 or C46400 |

| Applications | Precision components, gears, fittings | Decorative hardware, trim, fixtures |

| Finish Quality | Good machinability, smooth finishes | Superior surface finish, enhanced aesthetics |

| Corrosion Resistance | Moderate, suitable for controlled environments | High, ideal for indoor/outdoor use |

| Mechanical Properties | Excellent machinability, moderate strength | Durable, high strength, less machinable |

| Cost | Generally lower cost | Higher cost due to enhanced alloying and finish |

Introduction to Machinable Brass and Architectural Brass

Machinable brass is a type of brass alloy specifically engineered for high precision machining, featuring excellent machinability due to its controlled composition of copper, zinc, and often lead. Architectural brass is prized for its aesthetic appeal and corrosion resistance, commonly used in decorative applications such as hardware, trim, and fittings, with a composition optimized for durability and surface finish. Both alloys leverage the versatility of brass but differ significantly in their formulation and intended applications, with machinable brass prioritizing ease of fabrication and architectural brass emphasizing appearance and longevity.

Key Differences in Composition and Properties

Machinable brass typically contains higher lead content, around 2-3%, enhancing its machinability and making it ideal for precision components, whereas architectural brass has lower or no lead content, prioritizing corrosion resistance and aesthetic appeal for decorative applications. The composition of machinable brass often includes zinc and copper with lead for improved cutting and shaping, while architectural brass emphasizes durability, weather resistance, and a smooth, polished finish. These differences in composition result in machinable brass being softer and easier to work with, whereas architectural brass offers superior strength and visual qualities suited for structural and ornamental use.

Machinability: Ease of Fabrication and Processing

Machinable brass, often alloyed with added lead, offers superior machinability due to its low tool wear and exceptional chip formation, making it ideal for precision parts requiring tight tolerances. Architectural brass, typically composed of higher copper content for aesthetics and corrosion resistance, presents greater challenges in fabrication, with slower cutting speeds and increased tool wear. Manufacturers favor machinable brass in applications demanding efficient processing and high-volume production, while architectural brass is selected primarily for visual appeal and durability in exterior environments.

Architectural Brass: Aesthetic and Structural Qualities

Architectural brass boasts superior aesthetic qualities with its warm golden hue and brilliant luster, enhancing both historical and modern building designs. Its corrosion resistance and durability make it ideal for high-traffic areas, maintaining structural integrity while providing elegant finishes. Commonly used in decorative hardware, railings, and fixtures, architectural brass combines strength with visual appeal to elevate interior and exterior architectural elements.

Common Applications of Machinable Brass

Machinable brass is widely used in precision components such as gears, valves, and fittings due to its excellent machinability and corrosion resistance. Its applications extend to manufacturing intricate parts in plumbing, electrical connectors, and musical instruments where dimensional accuracy is critical. Unlike architectural brass, which emphasizes aesthetic appeal, machinable brass prioritizes functionality in mechanical and industrial settings.

Typical Uses of Architectural Brass in Design

Architectural brass is commonly used in design for decorative hardware, including door handles, railings, and fixtures, due to its aesthetic appeal and corrosion resistance. Its ability to maintain a polished finish makes it ideal for interior elements like trims, elevator panels, and light switch plates. The alloy's durability and workability enable custom designs in high-traffic environments such as hotels and commercial buildings.

Durability and Corrosion Resistance Comparison

Machinable brass offers excellent durability with high tensile strength and good wear resistance, making it suitable for components requiring precision and longevity. Architectural brass prioritizes superior corrosion resistance and aesthetic appeal, often enhanced with protective coatings to withstand harsh environmental conditions. Both types balance durability and corrosion resistance differently, with machinable brass excelling in mechanical performance and architectural brass excelling in weathering and visual integrity.

Cost Considerations: Machinable vs Architectural Brass

Machinable brass typically incurs higher costs due to its enhanced machinability, allowing for precision cutting and minimal tool wear, which reduces production time and labor expenses. Architectural brass, designed primarily for aesthetic appeal and corrosion resistance, tends to have lower raw material costs but may require additional finishing processes that increase overall expenses. Evaluating cost considerations involves balancing machining efficiency against finishing requirements based on the intended application.

Environmental Impact and Sustainability Factors

Machinable brass, often containing lead for improved machinability, poses environmental concerns due to lead toxicity and challenges in recycling compared to architectural brass, which typically uses lead-free or low-lead alloys promoting safer disposal and higher recyclability. Architectural brass supports sustainability through its durability, resistance to corrosion, and potential for reuse in construction applications, reducing resource consumption over time. The environmental impact of machining processes for brass also varies, with lead-free formulations decreasing hazardous waste generation and aligning better with green manufacturing standards.

Choosing the Right Brass for Your Project

Machinable brass, known for its superior machinability and strength, is ideal for precision components and mechanical parts requiring tight tolerances and durability. Architectural brass, valued for its aesthetic appeal and corrosion resistance, is best suited for decorative applications such as fixtures, railings, and trim where appearance is paramount. Selecting the right brass depends on balancing functional requirements like machinability and corrosion resistance with the desired visual finish and environmental exposure.

Machinable Brass vs Architectural Brass Infographic

materialdif.com

materialdif.com