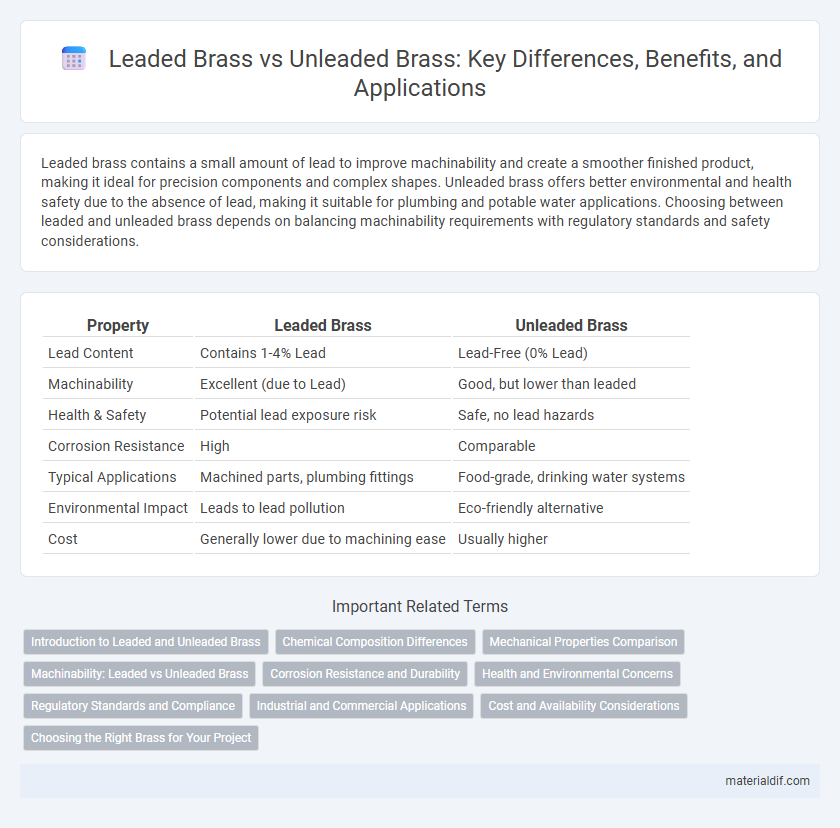

Leaded brass contains a small amount of lead to improve machinability and create a smoother finished product, making it ideal for precision components and complex shapes. Unleaded brass offers better environmental and health safety due to the absence of lead, making it suitable for plumbing and potable water applications. Choosing between leaded and unleaded brass depends on balancing machinability requirements with regulatory standards and safety considerations.

Table of Comparison

| Property | Leaded Brass | Unleaded Brass |

|---|---|---|

| Lead Content | Contains 1-4% Lead | Lead-Free (0% Lead) |

| Machinability | Excellent (due to Lead) | Good, but lower than leaded |

| Health & Safety | Potential lead exposure risk | Safe, no lead hazards |

| Corrosion Resistance | High | Comparable |

| Typical Applications | Machined parts, plumbing fittings | Food-grade, drinking water systems |

| Environmental Impact | Leads to lead pollution | Eco-friendly alternative |

| Cost | Generally lower due to machining ease | Usually higher |

Introduction to Leaded and Unleaded Brass

Leaded brass contains typically 2-3% lead, enhancing machinability and improving cutting performance in manufacturing processes, making it a preferred choice for precision components. Unleaded brass, often alloyed with bismuth or silicon, provides a safer alternative for applications requiring environmental compliance and reduced toxicity, particularly in plumbing and drinking water systems. Understanding the composition differences between leaded and unleaded brass is essential for selecting the appropriate material based on mechanical properties and regulatory standards.

Chemical Composition Differences

Leaded brass contains a small percentage of lead, typically around 2-3%, which improves machinability and lubricity during manufacturing. Unleaded brass, on the other hand, excludes lead and often incorporates elements like silicon, manganese, or aluminum to enhance strength and corrosion resistance. The absence of lead in unleaded brass also reduces health risks, making it suitable for plumbing and drinking water applications.

Mechanical Properties Comparison

Leaded brass offers superior machinability and higher ductility due to the presence of lead, which acts as a lubricant during cutting processes, resulting in smoother finishes and reduced tool wear. Unleaded brass typically exhibits greater tensile strength and corrosion resistance, making it more suitable for high-stress and demanding environmental applications. The mechanical property trade-off between leaded and unleaded brass should be carefully considered based on specific requirements for strength, machinability, and environmental compliance.

Machinability: Leaded vs Unleaded Brass

Leaded brass contains approximately 2-3% lead, significantly enhancing its machinability by reducing tool wear and improving chip formation. Unleaded brass, compliant with environmental and health regulations, offers lower machinability due to the absence of lead, often requiring optimized cutting parameters or alternative alloying elements. Industrial applications demanding high precision and efficient machining favor leaded brass, while unleaded brass is preferred in eco-sensitive contexts despite its more challenging machining characteristics.

Corrosion Resistance and Durability

Leaded brass offers enhanced machinability but generally exhibits lower corrosion resistance compared to unleaded brass, which contains safer alloys and improved environmental compliance. Unleaded brass demonstrates superior durability in harsh environments due to its reduced lead content and higher resistance to dezincification, making it ideal for plumbing and marine applications. Choosing unleaded brass ensures longer service life and better performance in corrosive conditions, aligning with modern safety and environmental standards.

Health and Environmental Concerns

Leaded brass contains small amounts of lead, enhancing machinability but posing health risks due to lead exposure, which can cause neurological and reproductive issues. Unleaded brass eliminates these health hazards, making it safer for plumbing and food-contact applications while reducing environmental contamination through lead leaching. Regulatory agencies increasingly favor unleaded brass to minimize toxic lead pollution in water systems and soil ecosystems.

Regulatory Standards and Compliance

Leaded brass contains small amounts of lead to enhance machinability but faces strict regulations such as the RoHS Directive limiting lead content to reduce environmental and health risks. Unleaded brass complies with stringent regulatory standards including the Safe Drinking Water Act (SDWA) and California's AB1953, ensuring it is safe for potable water applications and free from harmful lead levels. Manufacturers prioritizing compliance choose unleaded brass to meet global environmental and safety requirements while maintaining performance.

Industrial and Commercial Applications

Leaded brass offers superior machinability and corrosion resistance, making it ideal for complex industrial components such as valves, fittings, and gears used in automotive and plumbing industries. Unleaded brass, free from harmful lead content, is preferred in commercial applications requiring strict compliance with health and safety standards, including food processing equipment and potable water fittings. Both materials deliver excellent thermal and electrical conductivity, but the choice depends on regulatory requirements and specific performance needs in industrial or commercial environments.

Cost and Availability Considerations

Leaded brass typically costs less than unleaded brass due to simpler manufacturing processes and readily available lead additives, making it a budget-friendly option for many applications. Unleaded brass, favored for environmental and health reasons, is often more expensive and may have limited availability depending on regional regulations and supplier stock. Both materials are widely available, but fluctuating demand and regulatory restrictions can impact leaded brass supply chains more significantly.

Choosing the Right Brass for Your Project

Choosing the right brass alloy depends on the application's safety requirements and machinability, with leaded brass offering superior ease of machining due to added lead content, making it ideal for complex parts. Unleaded brass provides a safer option for potable water or food-contact projects, complying with environmental and health regulations limiting lead exposure. Evaluating mechanical properties, regulatory standards, and end-use conditions ensures optimal brass selection balancing performance and safety.

Leaded Brass vs Unleaded Brass Infographic

materialdif.com

materialdif.com