Forged brass is produced by shaping heated brass under high pressure, resulting in a denser and stronger material with superior mechanical properties compared to cast brass. Cast brass is made by pouring molten brass into molds, which allows more complex shapes but often leads to a coarser grain structure and reduced strength. The choice between forged and cast brass depends on the application, balancing the need for durability with design complexity.

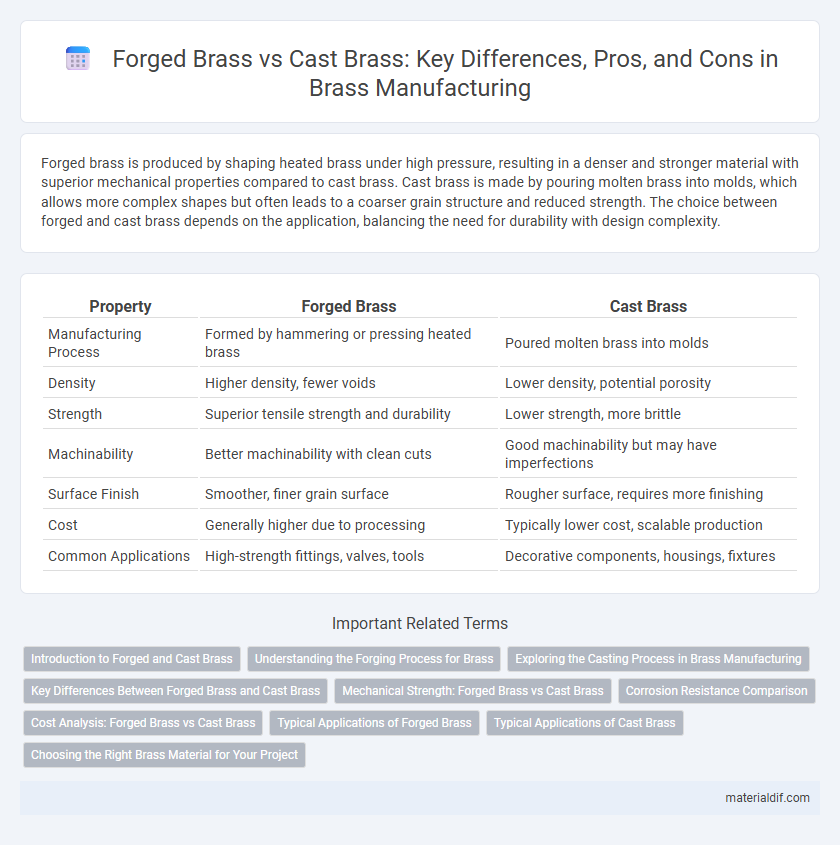

Table of Comparison

| Property | Forged Brass | Cast Brass |

|---|---|---|

| Manufacturing Process | Formed by hammering or pressing heated brass | Poured molten brass into molds |

| Density | Higher density, fewer voids | Lower density, potential porosity |

| Strength | Superior tensile strength and durability | Lower strength, more brittle |

| Machinability | Better machinability with clean cuts | Good machinability but may have imperfections |

| Surface Finish | Smoother, finer grain surface | Rougher surface, requires more finishing |

| Cost | Generally higher due to processing | Typically lower cost, scalable production |

| Common Applications | High-strength fittings, valves, tools | Decorative components, housings, fixtures |

Introduction to Forged and Cast Brass

Forged brass is produced by heating and shaping solid brass billets under high pressure, resulting in a denser and stronger material with improved mechanical properties. Cast brass is made by pouring molten brass into molds, allowing complex shapes and intricate designs but often with a coarser grain structure and potential porosity. Forged brass typically offers superior durability and finish quality compared to cast brass, making it ideal for high-stress applications.

Understanding the Forging Process for Brass

The forging process for brass involves heating a solid billet of brass until it becomes malleable, then applying high pressure to shape it into the desired form, resulting in a denser and stronger material compared to casting. Forged brass exhibits improved mechanical properties such as increased tensile strength and resistance to fatigue due to the refined grain structure created during deformation. This method is preferred in applications requiring superior durability and precision, including plumbing fittings, musical instruments, and aerospace components.

Exploring the Casting Process in Brass Manufacturing

The casting process in brass manufacturing involves pouring molten brass into molds to create complex shapes with consistent thicknesses, making cast brass ideal for intricate and detailed designs. Forged brass, however, is produced by shaping solid brass billets under high pressure, resulting in superior strength and durability due to its refined grain structure. Understanding these differences helps manufacturers select the appropriate method based on product requirements such as mechanical performance and design complexity.

Key Differences Between Forged Brass and Cast Brass

Forged brass offers superior strength and durability due to its manufacturing process, which involves shaping metal under high pressure, resulting in a dense and fine-grained structure. Cast brass is created by pouring molten metal into molds, producing a more uniform and intricate design but with reduced mechanical strength and higher porosity. The enhanced tensile strength and wear resistance of forged brass make it ideal for high-stress applications, while cast brass suits decorative and complex-shaped components.

Mechanical Strength: Forged Brass vs Cast Brass

Forged brass exhibits superior mechanical strength compared to cast brass due to its denser microstructure and refined grain alignment achieved through the forging process. The forging method reduces internal porosity and improves tensile strength, making forged brass ideal for high-stress applications requiring durability and resistance to deformation. In contrast, cast brass tends to have a coarser grain and higher porosity, resulting in lower mechanical strength and increased brittleness.

Corrosion Resistance Comparison

Forged brass exhibits superior corrosion resistance compared to cast brass due to its denser microstructure and reduced porosity, which limits exposure to corrosive agents. Cast brass tends to have microscopic voids and impurities from the molding process, making it more susceptible to oxidation and dezincification. For applications requiring enhanced durability in corrosive environments, forged brass is the preferred material choice.

Cost Analysis: Forged Brass vs Cast Brass

Forged brass generally incurs higher production costs compared to cast brass due to the labor-intensive forging process and the need for specialized equipment, which translates to increased material waste and energy consumption. Cast brass, produced through molding molten metal into shapes, offers more cost-effective manufacturing with lower tooling expenses and faster production cycles, making it suitable for large-scale, complex components. Cost analysis shows forged brass is preferred for applications requiring superior mechanical strength and durability despite its premium price, while cast brass is economical for intricate designs and bulk manufacturing.

Typical Applications of Forged Brass

Forged brass is commonly used in applications requiring high strength and durability, such as valves, fittings, and fasteners for plumbing and industrial machinery. The forging process enhances the metal's mechanical properties, making it ideal for components subjected to high pressure and mechanical stress. Typical industries utilizing forged brass include automotive, aerospace, and construction, where reliability and resistance to wear are essential.

Typical Applications of Cast Brass

Cast brass is typically used in applications requiring complex shapes and detailed designs, such as decorative fixtures, marine hardware, and plumbing components. Its excellent corrosion resistance and good machinability make it ideal for valve bodies, fittings, and ornamental pieces. Industries often prefer cast brass for producing precision instruments and electrical connectors due to its stability and durability.

Choosing the Right Brass Material for Your Project

Forged brass offers superior strength, durability, and resistance to fatigue, making it ideal for high-stress applications such as plumbing fittings and valves. Cast brass provides more intricate shapes and cost-effectiveness, suitable for decorative hardware and complex components where precision molding is essential. Selecting the right brass material depends on balancing mechanical requirements and design complexity to ensure optimal performance and longevity for your project.

Forged Brass vs Cast Brass Infographic

materialdif.com

materialdif.com