Naval brass, an alloy composed primarily of copper, zinc, and a small percentage of tin, offers excellent corrosion resistance, especially in seawater applications, making it ideal for marine fittings and valves. Admiralty brass contains a higher tin content compared to naval brass, enhancing its strength and resistance to dezincification, which is critical for long-term durability in aggressive marine environments. Both alloys are essential in naval engineering, but Admiralty brass is preferred where superior mechanical properties and corrosion resistance are required.

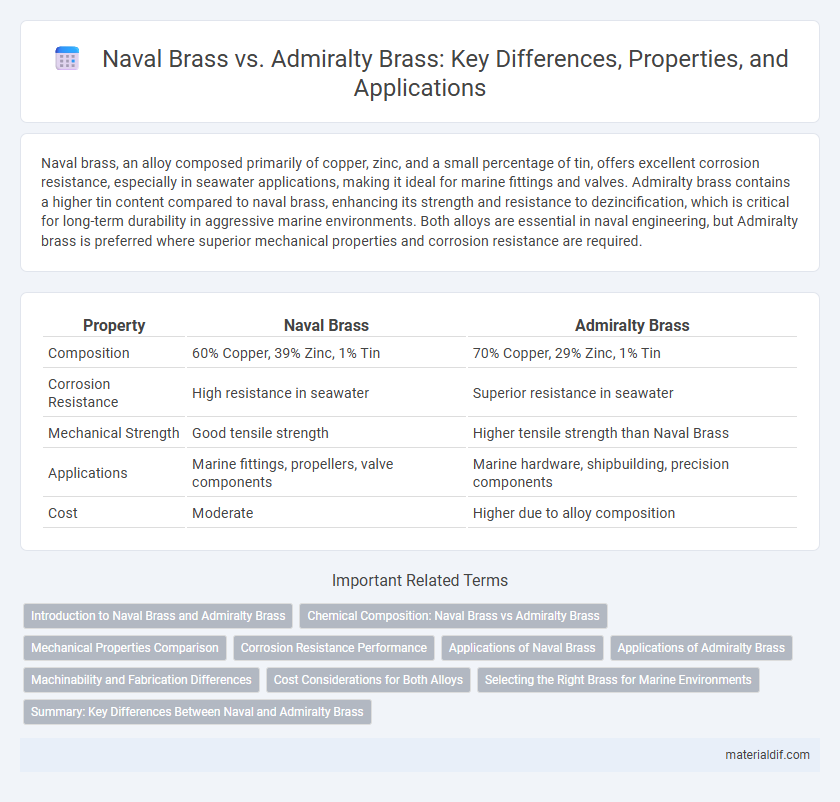

Table of Comparison

| Property | Naval Brass | Admiralty Brass |

|---|---|---|

| Composition | 60% Copper, 39% Zinc, 1% Tin | 70% Copper, 29% Zinc, 1% Tin |

| Corrosion Resistance | High resistance in seawater | Superior resistance in seawater |

| Mechanical Strength | Good tensile strength | Higher tensile strength than Naval Brass |

| Applications | Marine fittings, propellers, valve components | Marine hardware, shipbuilding, precision components |

| Cost | Moderate | Higher due to alloy composition |

Introduction to Naval Brass and Admiralty Brass

Naval Brass is a copper-zinc alloy with approximately 60% copper, 39% zinc, and 1% tin, renowned for its exceptional corrosion resistance in seawater environments. Admiralty Brass, differing slightly by including about 1% tin along with copper and zinc, offers superior strength and resistance to dezincification, making it ideal for marine hardware and shipbuilding applications. Both alloys are widely used in maritime industries due to their durability and ability to withstand harsh aquatic conditions.

Chemical Composition: Naval Brass vs Admiralty Brass

Naval Brass typically contains 60-63% copper, 2.5-3% zinc, 0.5-1% tin, and small amounts of lead, which enhances its corrosion resistance and machinability. Admiralty Brass, on the other hand, includes about 70% copper, 29% zinc, and 1% tin, resulting in improved strength and resistance to dezincification in seawater environments. The higher tin content in Naval Brass provides superior protection against saltwater corrosion compared to Admiralty Brass, making it preferred for marine applications.

Mechanical Properties Comparison

Naval Brass exhibits superior corrosion resistance and higher tensile strength, typically around 550 MPa, compared to Admiralty Brass, which generally has tensile strength near 400 MPa. Admiralty Brass offers better machinability and enhanced thermal conductivity but shows lower resistance to dezincification under marine conditions. Mechanical properties such as yield strength, elongation, and hardness favor Naval Brass for heavy-duty marine applications requiring durability and structural integrity.

Corrosion Resistance Performance

Naval Brass, composed mainly of copper, zinc, and tin, exhibits superior corrosion resistance in seawater environments due to its enhanced tin content, which forms a protective oxide layer. Admiralty Brass, while also containing copper, zinc, and tin, has a slightly lower tin percentage, making it more vulnerable to dezincification and corrosion under prolonged exposure to saltwater. This difference in alloy composition results in Naval Brass being the preferred choice for marine applications requiring high durability and resistance to seawater corrosion.

Applications of Naval Brass

Naval Brass is extensively used in marine applications due to its excellent corrosion resistance in seawater environments, making it ideal for ship fittings, pumps, valves, and propellers. Its copper-zinc-tin alloy composition provides superior strength and durability compared to Admiralty Brass, which is typically favored for corrosion-resistant marine hardware but with different mechanical properties. The use of Naval Brass ensures reliability in harsh maritime settings, particularly where resistance to dezincification and stress corrosion cracking is critical.

Applications of Admiralty Brass

Admiralty brass, an alloy composed of copper, zinc, and a small amount of tin, is primarily used in marine applications due to its excellent resistance to seawater corrosion and biofouling. It is commonly found in shipbuilding components, such as condenser tubes, pump parts, and valve bodies, where durability and corrosion resistance are critical. Its superior mechanical properties and resistance to dezincification make Admiralty brass ideal for seawater piping systems and heat exchangers in naval and offshore environments.

Machinability and Fabrication Differences

Naval Brass contains about 60% copper, 39% zinc, and 1% tin, enhancing its corrosion resistance and machinability in marine environments. Admiralty Brass, with a slightly higher copper content near 70% and 1% tin, offers superior strength but reduced machinability due to its denser microstructure. Fabrication of Naval Brass typically requires less tool wear and energy, while Admiralty Brass demands specialized machining techniques to manage its hardness and brittleness.

Cost Considerations for Both Alloys

Naval Brass, typically composed of copper, zinc, and tin, is generally more expensive than Admiralty Brass due to its superior corrosion resistance and mechanical strength, making it ideal for marine environments. Admiralty Brass contains a higher zinc content and less tin, reducing manufacturing costs but also resulting in lower durability against seawater exposure. When selecting between these alloys, cost considerations involve balancing initial material expense against long-term maintenance and replacement costs in maritime applications.

Selecting the Right Brass for Marine Environments

Naval Brass, an alloy with approximately 60% copper, 39% zinc, and 1% tin, offers superior corrosion resistance in seawater due to its enhanced tin content, making it ideal for marine fittings and propellers. Admiralty Brass, containing roughly 70% copper, 29% zinc, and 1% tin, provides excellent machinability and strength but has slightly lower resistance to dezincification compared to Naval Brass. Selecting the right brass for marine environments depends on factors such as exposure to seawater, mechanical stress requirements, and the necessity for resistance to dezincification and corrosion.

Summary: Key Differences Between Naval and Admiralty Brass

Naval Brass contains approximately 60% copper, 39% zinc, and 1% tin, offering superior corrosion resistance, especially in seawater environments, while Admiralty Brass has a slightly lower zinc content and includes a small amount of tin to enhance strength and machinability. Naval Brass is preferred for marine applications requiring high resistance to dezincification and biofouling, whereas Admiralty Brass is commonly used in industrial components like pumps and valves due to its improved mechanical properties. The primary distinction lies in their tin content and zinc percentage, which directly impact their durability and suitability for specific aquatic and engineering uses.

Naval Brass vs Admiralty Brass Infographic

materialdif.com

materialdif.com