Eco Brass stands out for its environmentally friendly composition, reducing harmful elements commonly found in traditional brass such as lead and nickel. This sustainable alloy enhances recyclability and minimizes toxic exposure, making it safer for both manufacturers and end-users. Its durability and corrosion resistance maintain the functional benefits of traditional brass while promoting a greener manufacturing process.

Table of Comparison

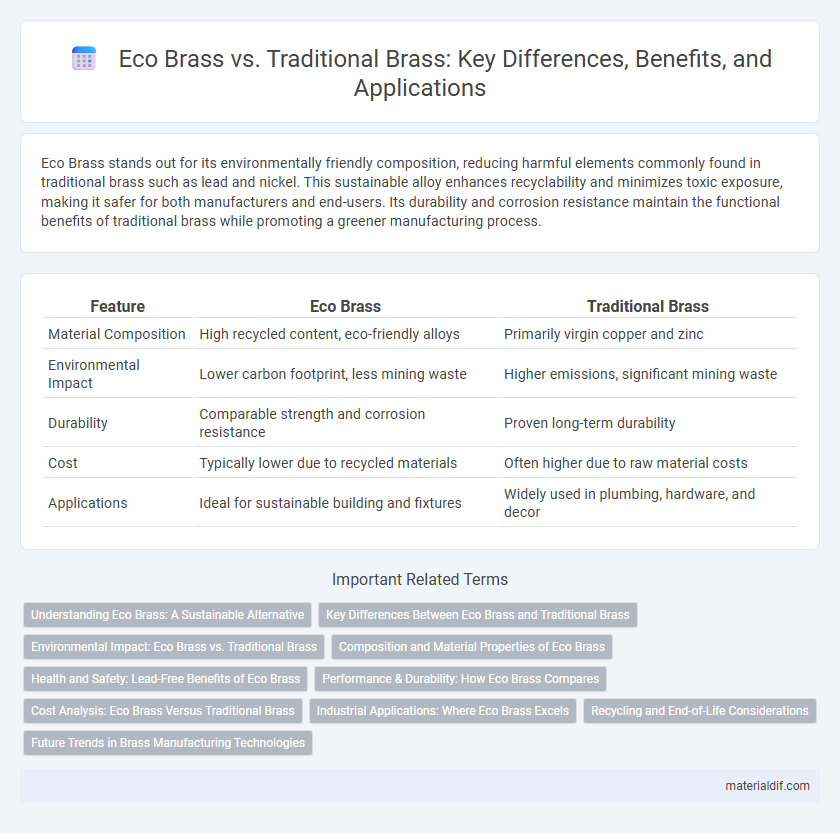

| Feature | Eco Brass | Traditional Brass |

|---|---|---|

| Material Composition | High recycled content, eco-friendly alloys | Primarily virgin copper and zinc |

| Environmental Impact | Lower carbon footprint, less mining waste | Higher emissions, significant mining waste |

| Durability | Comparable strength and corrosion resistance | Proven long-term durability |

| Cost | Typically lower due to recycled materials | Often higher due to raw material costs |

| Applications | Ideal for sustainable building and fixtures | Widely used in plumbing, hardware, and decor |

Understanding Eco Brass: A Sustainable Alternative

Eco Brass is an innovative, sustainable alternative to traditional brass, designed to reduce environmental impact by incorporating recycled materials and minimizing harmful chemicals during production. Unlike conventional brass, Eco Brass offers improved corrosion resistance and durability while maintaining comparable mechanical properties, making it ideal for both industrial and decorative applications. Its eco-friendly manufacturing process significantly lowers carbon emissions and energy consumption, supporting green building standards and circular economy principles.

Key Differences Between Eco Brass and Traditional Brass

Eco Brass is manufactured using recycled materials and sustainable processes that reduce environmental impact, whereas Traditional Brass relies heavily on virgin raw materials and energy-intensive production. Eco Brass typically contains lower levels of toxic elements like lead, enhancing its safety for plumbing and consumer products compared to Traditional Brass. The durability and corrosion resistance of Eco Brass remain comparable to Traditional Brass, making it a responsible choice without compromising performance.

Environmental Impact: Eco Brass vs. Traditional Brass

Eco Brass significantly reduces environmental impact by utilizing recycled materials and lower energy consumption during production compared to Traditional Brass. The manufacturing process of Eco Brass emits fewer greenhouse gases and generates less industrial waste, contributing to sustainable resource management. Traditional Brass often relies on virgin metal extraction, which causes higher ecological degradation and energy-intensive processing.

Composition and Material Properties of Eco Brass

Eco Brass is an alloy primarily composed of copper, zinc, and a significantly reduced amount of lead, typically less than 0.1%, compared to traditional brass which can contain up to 2.5% lead. This lower lead content enhances its environmental and health safety, while maintaining excellent machinability and corrosion resistance. Eco Brass exhibits similar mechanical strength and thermal conductivity to traditional brass, making it a sustainable yet effective alternative for plumbing and electrical applications.

Health and Safety: Lead-Free Benefits of Eco Brass

Eco Brass offers significant health and safety advantages over traditional brass by being lead-free, reducing the risk of lead exposure in plumbing and fixtures. Lead-free composition prevents leaching into potable water, ensuring safer drinking water and compliance with stringent health regulations. This makes Eco Brass an ideal choice for environments prioritizing human health and environmental safety.

Performance & Durability: How Eco Brass Compares

Eco Brass exhibits enhanced corrosion resistance and superior tensile strength compared to traditional brass, ensuring longer service life in demanding applications. Its optimized alloy composition reduces environmental impact without compromising mechanical performance, making it highly durable in both marine and industrial environments. Performance tests demonstrate Eco Brass maintains structural integrity under higher stress conditions, outperforming conventional brass in wear resistance and operational longevity.

Cost Analysis: Eco Brass Versus Traditional Brass

Eco brass typically offers a cost advantage over traditional brass due to lower energy consumption and reduced raw material waste during production. The initial price per unit of eco brass may be slightly higher, but long-term savings arise from improved manufacturing efficiency and decreased environmental compliance costs. When factoring in lifecycle expenses, eco brass proves more economical, especially for large-scale industrial applications seeking sustainable solutions.

Industrial Applications: Where Eco Brass Excels

Eco Brass offers superior corrosion resistance and reduced lead content compared to traditional brass, making it ideal for industrial applications requiring strict environmental and safety standards. Its enhanced machinability lowers production costs and improves efficiency in manufacturing precision components such as valves, fittings, and gears. Industries focused on sustainability increasingly prefer Eco Brass for its compliance with green regulations and reduced environmental impact.

Recycling and End-of-Life Considerations

Eco Brass significantly reduces environmental impact by incorporating a higher percentage of recycled copper and zinc, minimizing raw material extraction. Traditional Brass, while durable, often relies more heavily on virgin metals, leading to increased energy consumption and waste generation during production. At end-of-life, Eco Brass is easier to recycle due to its standardized composition and lower contamination risk, enhancing material recovery and supporting circular economy goals.

Future Trends in Brass Manufacturing Technologies

Eco brass integrates recycled materials and low-emission processes, reducing environmental impact in brass manufacturing. Emerging trends emphasize advanced alloy formulations and energy-efficient production methods to enhance sustainability and material performance. Future brass manufacturing technologies are anticipated to prioritize circular economy principles and smart automation for improved resource optimization.

Eco Brass vs Traditional Brass Infographic

materialdif.com

materialdif.com