Cast brass offers intricate shapes and complex designs due to its molten pouring process, making it ideal for decorative pet accessories. Wrought brass involves mechanical working like rolling or forging, resulting in stronger, more durable components suitable for everyday use. Choosing between cast and wrought brass depends on whether aesthetics or structural integrity is the priority for your pet item.

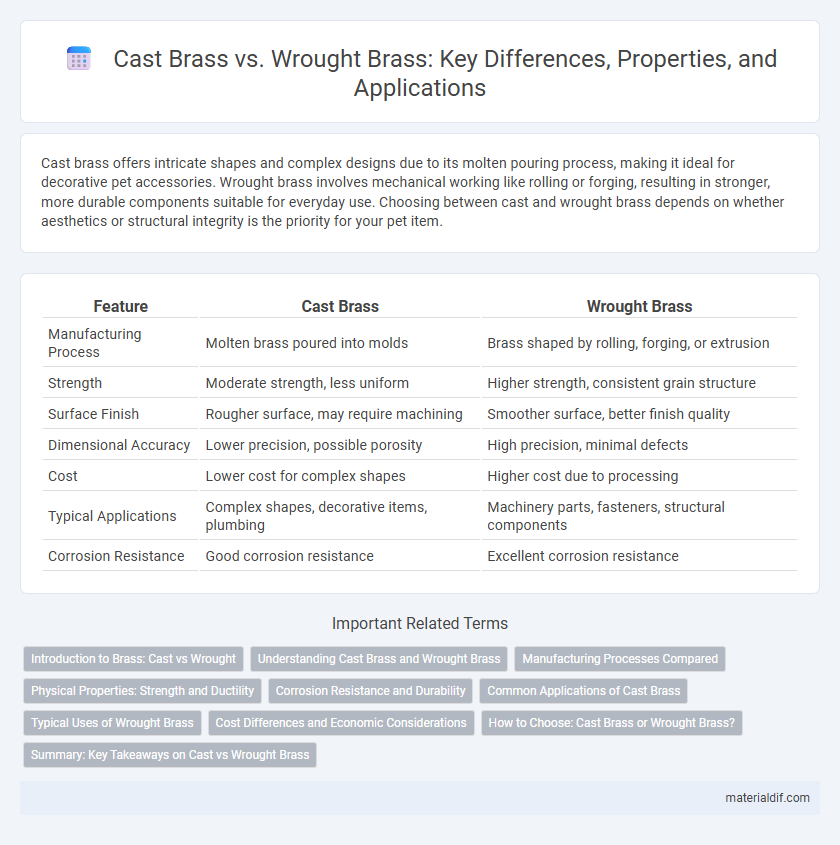

Table of Comparison

| Feature | Cast Brass | Wrought Brass |

|---|---|---|

| Manufacturing Process | Molten brass poured into molds | Brass shaped by rolling, forging, or extrusion |

| Strength | Moderate strength, less uniform | Higher strength, consistent grain structure |

| Surface Finish | Rougher surface, may require machining | Smoother surface, better finish quality |

| Dimensional Accuracy | Lower precision, possible porosity | High precision, minimal defects |

| Cost | Lower cost for complex shapes | Higher cost due to processing |

| Typical Applications | Complex shapes, decorative items, plumbing | Machinery parts, fasteners, structural components |

| Corrosion Resistance | Good corrosion resistance | Excellent corrosion resistance |

Introduction to Brass: Cast vs Wrought

Cast brass is produced by pouring molten brass into molds, resulting in a material with excellent fluidity and the ability to form complex shapes with fine details. Wrought brass is mechanically worked through processes like rolling, forging, or extrusion, enhancing its strength and ductility compared to cast brass. The choice between cast and wrought brass depends on the application requirements such as dimensional precision, mechanical properties, and surface finish.

Understanding Cast Brass and Wrought Brass

Cast brass is formed by pouring molten brass into molds, resulting in intricate shapes with excellent dimensional accuracy and enhanced corrosion resistance. Wrought brass is produced by mechanically working solid brass billets through processes like rolling or forging, offering superior strength and ductility ideal for structural applications. Choosing between cast and wrought brass depends on the desired mechanical properties, complexity of design, and intended use in industries such as construction, plumbing, and decorative arts.

Manufacturing Processes Compared

Cast brass is produced by pouring molten brass into molds, allowing for complex shapes and detailed designs with minimal machining required, while wrought brass is created by mechanically deforming solid brass through processes such as rolling, forging, or extrusion, which enhances its strength and ductility. Casting offers the advantage of forming intricate geometries quickly, but wrought processes improve grain structure and mechanical properties, making wrought brass preferable for applications demanding higher durability. Differences in manufacturing impact surface finish, dimensional accuracy, and material properties, with cast brass often used for decorative components and wrought brass suited for structural and load-bearing parts.

Physical Properties: Strength and Ductility

Cast brass typically exhibits higher strength due to its solidified structure but lower ductility, making it more prone to brittleness under stress. Wrought brass, produced through mechanical working like rolling or forging, offers enhanced ductility and toughness, allowing it to deform without cracking. The differences in grain structure significantly influence mechanical behavior, with wrought brass favoring applications requiring flexibility and cast brass suited for rigid, load-bearing components.

Corrosion Resistance and Durability

Cast brass exhibits superior corrosion resistance due to its uniform alloy composition and controlled cooling process, which minimizes porosity and enhances durability in harsh environments. Wrought brass, while offering greater mechanical strength and flexibility, may have microstructural inconsistencies that slightly reduce its corrosion resistance compared to cast brass. The choice between cast and wrought brass depends on specific application requirements, balancing durability with resistance to environmental degradation.

Common Applications of Cast Brass

Cast brass is commonly used in applications requiring complex shapes and detailed designs such as decorative hardware, musical instruments, and plumbing fittings. Its ability to be molded into intricate forms makes it ideal for architectural components, valves, and intricate machine parts. The casting process allows for high durability and corrosion resistance, making cast brass suitable for both functional and aesthetic uses in various industries.

Typical Uses of Wrought Brass

Wrought brass is commonly used in applications requiring high strength and durability, such as architectural hardware, musical instruments, and marine fittings. Its ability to be cold-worked into complex shapes makes it ideal for precision components like gears, valves, and electrical connectors. The material's corrosion resistance and excellent machinability enhance its suitability for decorative and functional industrial uses.

Cost Differences and Economic Considerations

Cast brass typically involves lower production costs due to its molding process, making it more cost-effective for large, complex shapes. Wrought brass, manufactured through rolling or extrusion, incurs higher expenses from intensive labor and machinery requirements, resulting in increased prices. Economic considerations favor cast brass for budget-sensitive projects, while wrought brass is preferred for applications demanding superior mechanical properties and precision.

How to Choose: Cast Brass or Wrought Brass?

Choose cast brass for intricate designs and detailed components due to its excellent flow characteristics and ability to fill complex molds with high precision. Opt for wrought brass when superior mechanical strength, toughness, and ductility are essential, as cold working processes enhance its structural integrity and fatigue resistance. Consider application requirements such as corrosion resistance, dimensional accuracy, and manufacturing volume to select between cast and wrought brass effectively.

Summary: Key Takeaways on Cast vs Wrought Brass

Cast brass offers enhanced fluidity and complex shapes due to its molten metal pouring process, ideal for intricate components, while wrought brass is worked mechanically through rolling or extrusion, providing superior strength and uniform grain structure for durability. Cast brass tends to have a slightly lower tensile strength and is more brittle compared to wrought brass, which exhibits higher ductility and better resistance to fatigue and stress. Selecting between cast and wrought brass depends on the application's need for detailed geometry versus mechanical performance and toughness.

Cast Brass vs Wrought Brass Infographic

materialdif.com

materialdif.com