Phosphor bronze offers superior corrosion resistance and higher tensile strength compared to Admiralty brass, making it ideal for marine and electrical applications where durability is crucial. Admiralty brass, containing zinc and tin, provides excellent machinability and moderate corrosion resistance, commonly used in heat exchangers and condenser tubes. Choosing between the two depends on the balance needed between mechanical strength and ease of fabrication in specific industrial uses.

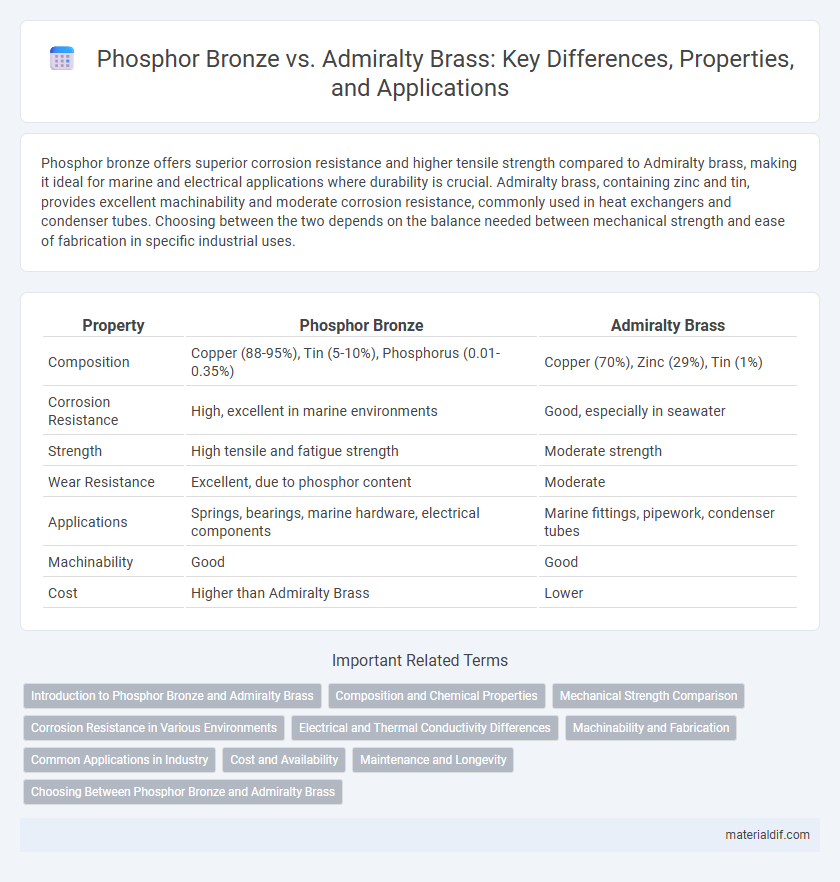

Table of Comparison

| Property | Phosphor Bronze | Admiralty Brass |

|---|---|---|

| Composition | Copper (88-95%), Tin (5-10%), Phosphorus (0.01-0.35%) | Copper (70%), Zinc (29%), Tin (1%) |

| Corrosion Resistance | High, excellent in marine environments | Good, especially in seawater |

| Strength | High tensile and fatigue strength | Moderate strength |

| Wear Resistance | Excellent, due to phosphor content | Moderate |

| Applications | Springs, bearings, marine hardware, electrical components | Marine fittings, pipework, condenser tubes |

| Machinability | Good | Good |

| Cost | Higher than Admiralty Brass | Lower |

Introduction to Phosphor Bronze and Admiralty Brass

Phosphor bronze is a copper alloy containing 0.5-11% tin and 0.01-0.35% phosphorus, renowned for its high strength, corrosion resistance, and excellent fatigue endurance. Admiralty brass consists primarily of copper (around 70%) with zinc (about 29%) and a small amount of tin (1%), valued for its superior resistance to seawater corrosion and good machinability. Both alloys are widely used in marine applications, with phosphor bronze favored for bearing and spring components, while Admiralty brass is preferred for marine hardware and condenser tubes.

Composition and Chemical Properties

Phosphor bronze consists primarily of copper (around 88-95%), tin (5-10%), and a small amount of phosphorus (0.01-0.35%), which enhances its wear resistance, stiffness, and corrosion resistance. Admiralty brass is an alloy of copper (approximately 70%), zinc (29.0-30.5%), and a small percentage of tin (around 1%), providing excellent resistance to marine corrosion and good strength. The presence of phosphorus in phosphor bronze improves its fatigue resistance and reduces friction, while the tin content in Admiralty brass contributes to its dezincification resistance and antimicrobial properties.

Mechanical Strength Comparison

Phosphor Bronze exhibits superior mechanical strength compared to Admiralty Brass, attributed to its higher copper and tin content combined with a small percentage of phosphorus, which enhances hardness and fatigue resistance. Admiralty Brass, primarily composed of copper, zinc, and a small amount of tin, offers moderate strength but excels in corrosion resistance, especially in marine environments. For applications requiring higher tensile strength and durability under mechanical stress, Phosphor Bronze is often the preferred choice over Admiralty Brass.

Corrosion Resistance in Various Environments

Phosphor bronze exhibits superior corrosion resistance compared to Admiralty brass, especially in marine environments due to its tin content, which enhances its resistance to seawater and salt spray. Admiralty brass, containing zinc and a small percentage of tin, provides good corrosion resistance but is more susceptible to dezincification in acidic or highly saline conditions. In industrial settings with exposure to chemicals or fresh water, phosphor bronze maintains structural integrity longer, making it preferable for applications demanding prolonged durability in corrosive environments.

Electrical and Thermal Conductivity Differences

Phosphor bronze exhibits lower electrical and thermal conductivity compared to Admiralty brass due to its higher tin and phosphorus content, which increases mechanical strength but reduces conductivity. Admiralty brass, primarily consisting of copper, zinc, and a small amount of tin, offers superior electrical conductivity around 28% IACS and better thermal conductivity, making it more suitable for electrical and heat transfer applications. These conductivity differences influence material selection in industries requiring efficient electrical performance and effective heat dissipation.

Machinability and Fabrication

Phosphor Bronze offers superior machinability compared to Admiralty Brass due to its uniform microstructure and lower lead content, resulting in smoother cutting and higher tool life. Admiralty Brass, while excellent in corrosion resistance and strength, poses challenges in fabrication because of its higher zinc and tin content, which can cause brittleness and reduce machinability. Manufacturers often prefer Phosphor Bronze for intricate machining and precision components, whereas Admiralty Brass suits applications requiring enhanced mechanical durability with moderate fabrication demands.

Common Applications in Industry

Phosphor bronze is widely used in electrical connectors, springs, and bushings due to its excellent corrosion resistance and high fatigue strength. Admiralty brass is favored in marine applications, such as shipbuilding and seawater piping, because of its superior resistance to dezincification and biofouling. Both alloys find critical roles in industries requiring durable, corrosion-resistant materials with specific mechanical properties.

Cost and Availability

Phosphor bronze generally costs more than Admiralty brass due to its higher copper and tin content, which enhances durability and corrosion resistance. Admiralty brass is more readily available and widely used in marine applications because of its favorable balance between cost and corrosion resistance. Availability of Admiralty brass remains higher in most markets, making it a cost-effective option for large-scale projects.

Maintenance and Longevity

Phosphor Bronze exhibits superior corrosion resistance and requires minimal maintenance, making it ideal for marine and industrial applications where longevity is critical. Admiralty Brass, while resistant to dezincification, demands more frequent inspections and cleaning to prevent surface degradation in harsh environments. The enhanced durability of Phosphor Bronze contributes to extended service life, reducing long-term upkeep costs compared to Admiralty Brass.

Choosing Between Phosphor Bronze and Admiralty Brass

Choosing between Phosphor Bronze and Admiralty Brass depends on the specific application requirements such as corrosion resistance, strength, and machinability. Phosphor Bronze offers superior wear resistance, higher fatigue strength, and better corrosion resistance in marine environments, making it ideal for springs, bearings, and electrical connectors. Admiralty Brass excels in machinability and provides good corrosion resistance in seawater, commonly used in valve and pump components where ease of fabrication is essential.

Phosphor Bronze vs Admiralty Brass Infographic

materialdif.com

materialdif.com