German Silver and Commercial Brass are two popular alloys used in brass pet products, offering distinct properties for different applications. German Silver, also known as nickel silver, contains copper, nickel, and zinc, providing enhanced corrosion resistance and a harder surface compared to Commercial Brass, which primarily consists of copper and zinc and is prized for its superior malleability and vibrant golden color. The choice between these materials depends on the balance needed between durability and aesthetic appeal in brass pet accessories.

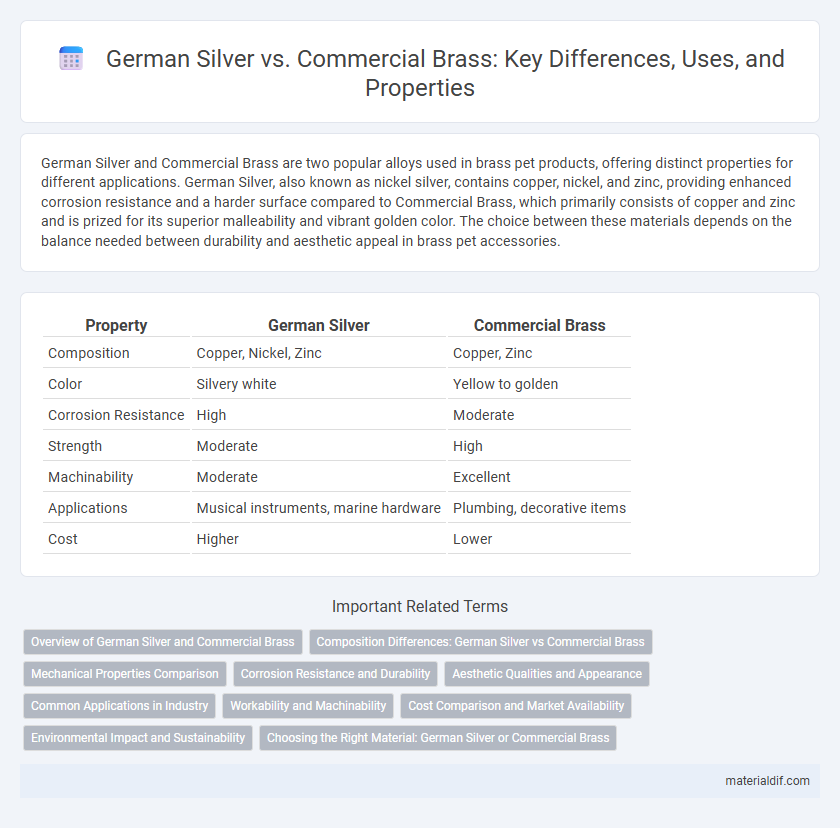

Table of Comparison

| Property | German Silver | Commercial Brass |

|---|---|---|

| Composition | Copper, Nickel, Zinc | Copper, Zinc |

| Color | Silvery white | Yellow to golden |

| Corrosion Resistance | High | Moderate |

| Strength | Moderate | High |

| Machinability | Moderate | Excellent |

| Applications | Musical instruments, marine hardware | Plumbing, decorative items |

| Cost | Higher | Lower |

Overview of German Silver and Commercial Brass

German Silver, also known as Nickel Silver, is an alloy composed mainly of copper, nickel, and zinc, notable for its silver-like appearance despite containing no actual silver. Commercial Brass primarily consists of copper and zinc, with varying compositions that influence its strength, corrosion resistance, and machinability. German Silver offers superior tarnish resistance and a more lustrous finish compared to standard Commercial Brass, making it preferred in decorative and musical instrument applications.

Composition Differences: German Silver vs Commercial Brass

German Silver, also known as nickel silver, is primarily an alloy of copper, nickel, and zinc, with typical composition around 60% copper, 20% nickel, and 20% zinc, which gives it a silver-like appearance without containing any actual silver. Commercial brass typically consists of copper and zinc, with copper content ranging from 55% to 95%, depending on the specific grade, and may include small amounts of other elements such as lead for machinability. The key compositional difference lies in the nickel content of German Silver, which is absent in most commercial brass alloys, impacting color, corrosion resistance, and mechanical properties.

Mechanical Properties Comparison

German Silver, an alloy primarily composed of copper, nickel, and zinc, exhibits superior corrosion resistance and tensile strength compared to commercial brass, which typically contains higher copper and zinc content. Commercial brass offers greater malleability and electrical conductivity but generally has lower hardness and mechanical stability under stress. The tensile strength of German Silver ranges around 450-570 MPa, while commercial brass usually falls between 300-500 MPa, making German Silver more suitable for applications requiring durability and wear resistance.

Corrosion Resistance and Durability

German Silver, an alloy consisting primarily of copper, nickel, and zinc, offers superior corrosion resistance compared to commercial brass, which is mostly copper and zinc. The presence of nickel in German Silver enhances its durability, making it more resistant to tarnishing and environmental wear over time. Commercial brass, while durable and widely used, tends to corrode faster in harsh conditions due to its lower nickel content.

Aesthetic Qualities and Appearance

German Silver, an alloy of copper, nickel, and zinc, exhibits a silvery-white appearance with a smooth, matte finish, making it ideal for modern, sleek designs. In contrast, Commercial Brass, primarily composed of copper and zinc, features a warm golden-yellow hue that develops a rich patina over time, enhancing its traditional aesthetic appeal. German Silver tends to resist tarnishing better, maintaining its lustrous look longer, while Commercial Brass offers a classic, radiant shine that deepens with age.

Common Applications in Industry

German silver, an alloy composed primarily of copper, nickel, and zinc, is widely used in applications requiring corrosion resistance and a silver-like appearance, such as in musical instruments, decorative hardware, and marine fittings. Commercial brass, typically an alloy of copper and zinc, finds extensive use in plumbing, electrical components, and automotive parts due to its excellent machinability and antimicrobial properties. Both alloys serve critical roles in manufacturing, but German silver's nickel content enhances durability in harsh environments, while commercial brass is preferred for its cost-effectiveness and versatility in everyday industrial applications.

Workability and Machinability

German Silver, an alloy primarily composed of copper, nickel, and zinc, offers superior corrosion resistance and excellent workability, making it ideal for intricate shaping and forming processes. Commercial brass, typically a copper-zinc alloy with variable zinc content, excels in machinability due to its softer nature and uniform grain structure, enabling faster cutting speeds and smoother finishes. The choice between German Silver and Commercial Brass depends on the specific requirements for forming complexity versus machining efficiency in manufacturing applications.

Cost Comparison and Market Availability

German Silver generally costs more than commercial brass due to its higher nickel content and specialized alloy composition, impacting production expenses. Commercial brass is widely available in the market at lower prices, benefiting from abundant raw materials and simpler manufacturing processes. The cost-effectiveness and extensive market availability of commercial brass make it a preferred choice for many industrial applications compared to the relatively pricier German Silver.

Environmental Impact and Sustainability

German Silver, an alloy typically composed of copper, nickel, and zinc, poses more environmental challenges than commercial brass due to its higher nickel content, which requires more intensive mining and processing, leading to greater ecological disruption and energy consumption. Commercial brass, consisting mainly of copper and zinc, generally has a lower environmental footprint since copper and zinc are more abundant and recyclable with less intensive processing. The sustainability of commercial brass is enhanced by its widespread recyclability and the lower toxicity of its constituent metals compared to the nickel-rich German Silver alloy.

Choosing the Right Material: German Silver or Commercial Brass

German Silver, an alloy of copper, nickel, and zinc, offers superior corrosion resistance and a silvery appearance ideal for decorative applications, while Commercial Brass, primarily composed of copper and zinc, provides excellent machinability and higher strength suited for structural and industrial components. Choosing between German Silver and Commercial Brass depends on the desired balance of aesthetics, durability, and mechanical properties; German Silver is preferred for tarnish resistance and visual appeal, whereas Commercial Brass excels in cost-effectiveness and ease of fabrication. For applications requiring long-term exposure to moisture or chemicals, German Silver's nickel content enhances longevity, whereas Commercial Brass is suitable for environments prioritizing toughness and economic efficiency.

German Silver vs Commercial Brass Infographic

materialdif.com

materialdif.com